Flip-chip LEDs offer enhanced thermal management and higher efficiency due to their direct contact with the substrate, while wire-bonded LEDs rely on fine wires for electrical connection, which can limit heat dissipation and device longevity. Discover how these differences impact your lighting applications by exploring the rest of this article.

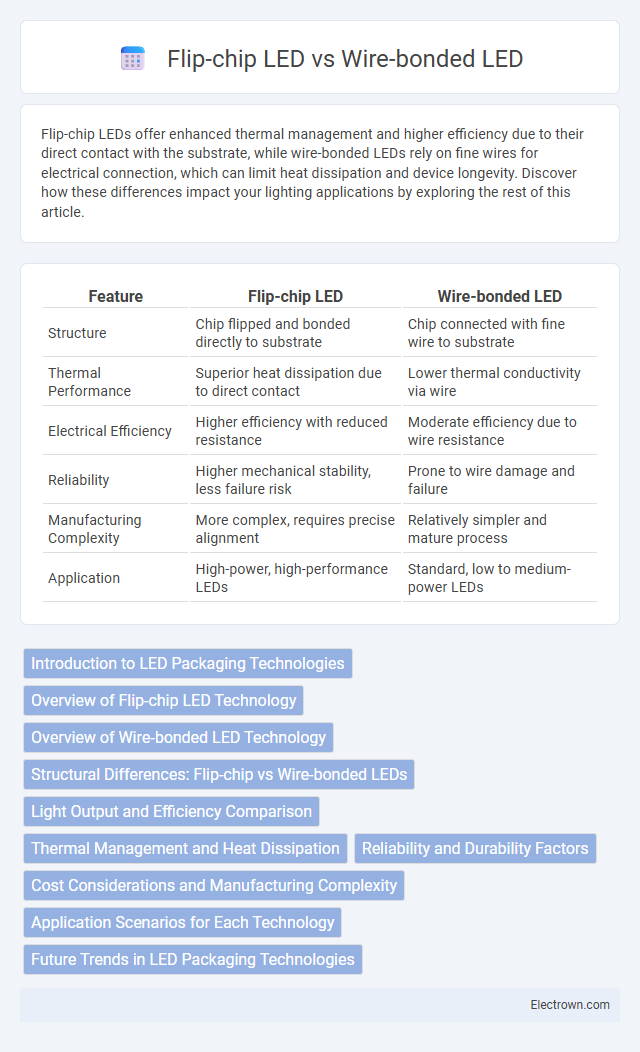

Table of Comparison

| Feature | Flip-chip LED | Wire-bonded LED |

|---|---|---|

| Structure | Chip flipped and bonded directly to substrate | Chip connected with fine wire to substrate |

| Thermal Performance | Superior heat dissipation due to direct contact | Lower thermal conductivity via wire |

| Electrical Efficiency | Higher efficiency with reduced resistance | Moderate efficiency due to wire resistance |

| Reliability | Higher mechanical stability, less failure risk | Prone to wire damage and failure |

| Manufacturing Complexity | More complex, requires precise alignment | Relatively simpler and mature process |

| Application | High-power, high-performance LEDs | Standard, low to medium-power LEDs |

Introduction to LED Packaging Technologies

Flip-chip LED packaging offers superior thermal management and enhanced light extraction by directly mounting the LED chip onto the substrate, reducing electrical resistance and improving heat dissipation compared to wire-bonded LEDs. Wire-bonded LED packaging involves connecting the chip to lead frames with fine metal wires, which can limit performance due to longer electrical paths and potential wire damage. Understanding these differences helps you choose the optimal LED packaging technology for applications requiring high efficiency and reliability.

Overview of Flip-chip LED Technology

Flip-chip LED technology involves mounting the LED chip directly onto the substrate with the light-emitting surface facing down, enhancing heat dissipation and electrical performance compared to wire-bonded LEDs. This configuration eliminates the need for wire bonds, reducing series resistance and inductance, which improves efficiency and reliability in high-power applications. Flip-chip LEDs also offer better light extraction efficiency due to minimized obstruction from wire bonds and improved thermal management.

Overview of Wire-bonded LED Technology

Wire-bonded LED technology uses thin metal wires to connect the LED chip to its package, providing electrical pathways while allowing heat dissipation through the package substrate. This method supports high-performance LED applications but may face limitations in thermal management and reliability compared to flip-chip LEDs. Understanding wire-bonded LED construction helps optimize your choices for lighting solutions where cost and established manufacturing processes are key factors.

Structural Differences: Flip-chip vs Wire-bonded LEDs

Flip-chip LEDs feature the semiconductor chip mounted directly onto the substrate with the active side facing down, enabling shorter electrical paths and improved thermal dissipation compared to wire-bonded LEDs. Wire-bonded LEDs connect the chip to the lead frame using thin metal wires, which can introduce higher resistance and limit heat management efficiency. Understanding these structural differences helps optimize Your LED choice for applications requiring enhanced performance and reliability.

Light Output and Efficiency Comparison

Flip-chip LEDs deliver higher light output and improved efficiency compared to wire-bonded LEDs due to their superior thermal management and reduced electrical resistance. The flip-chip design allows for direct heat dissipation through the substrate, resulting in lower junction temperatures and enhanced luminous efficacy. Your choice of LEDs can significantly impact performance, with flip-chip technology offering better energy savings and brighter illumination in demanding applications.

Thermal Management and Heat Dissipation

Flip-chip LEDs offer superior thermal management and heat dissipation compared to wire-bonded LEDs due to their direct substrate contact, which allows efficient heat transfer away from the junction. The absence of wire bonds reduces thermal resistance and minimizes hotspots, enhancing reliability and brightness stability. Improved heat dissipation in flip-chip designs results in lower junction temperatures, extending LED lifespan and performance in high-power applications.

Reliability and Durability Factors

Flip-chip LEDs offer enhanced thermal management due to their direct substrate contact, resulting in improved reliability and longer lifespan compared to wire-bonded LEDs prone to wire fatigue and delamination under thermal stress. The absence of fragile wire bonds in flip-chip designs reduces the risk of mechanical failure, making them more durable in harsh environments and high-vibration applications. Studies show flip-chip LEDs maintain consistent lumen output and color stability over extended operational hours, outperforming conventional wire-bonded LEDs in reliability metrics.

Cost Considerations and Manufacturing Complexity

Flip-chip LEDs typically offer lower thermal resistance and higher efficiency but involve higher initial manufacturing costs due to complex wafer-level processing and precise alignment requirements. Wire-bonded LEDs feature simpler assembly with established, cost-effective manufacturing techniques, making them more economical for large-scale production despite slightly reduced performance. Your choice between flip-chip and wire-bonded LED technologies should weigh these trade-offs in cost considerations and manufacturing complexity based on the specific application needs.

Application Scenarios for Each Technology

Flip-chip LEDs are ideal for high-power applications requiring superior heat dissipation and enhanced brightness, such as automotive headlights and large-scale signage displays. Wire-bonded LEDs are better suited for cost-sensitive, low to medium power uses like indicator lights and general illumination where simpler assembly and lower thermal management are sufficient. Each technology's characteristics dictate its optimal application, with flip-chip focusing on performance-critical environments and wire-bonded on economical, versatile lighting solutions.

Future Trends in LED Packaging Technologies

Flip-chip LED technology offers superior thermal management and higher luminous efficiency compared to traditional wire-bonded LEDs, positioning it as a leading solution in future LED packaging trends. Advances in materials and miniaturization are driving widespread adoption of flip-chip designs to meet growing demands for compact, high-performance lighting in automotive, display, and general illumination sectors. Your choice of LED packaging will increasingly favor flip-chip technology for enhanced reliability and energy efficiency as the market shifts toward smart and integrated lighting systems.

Flip-chip LED vs Wire-bonded LED Infographic

electrown.com

electrown.com