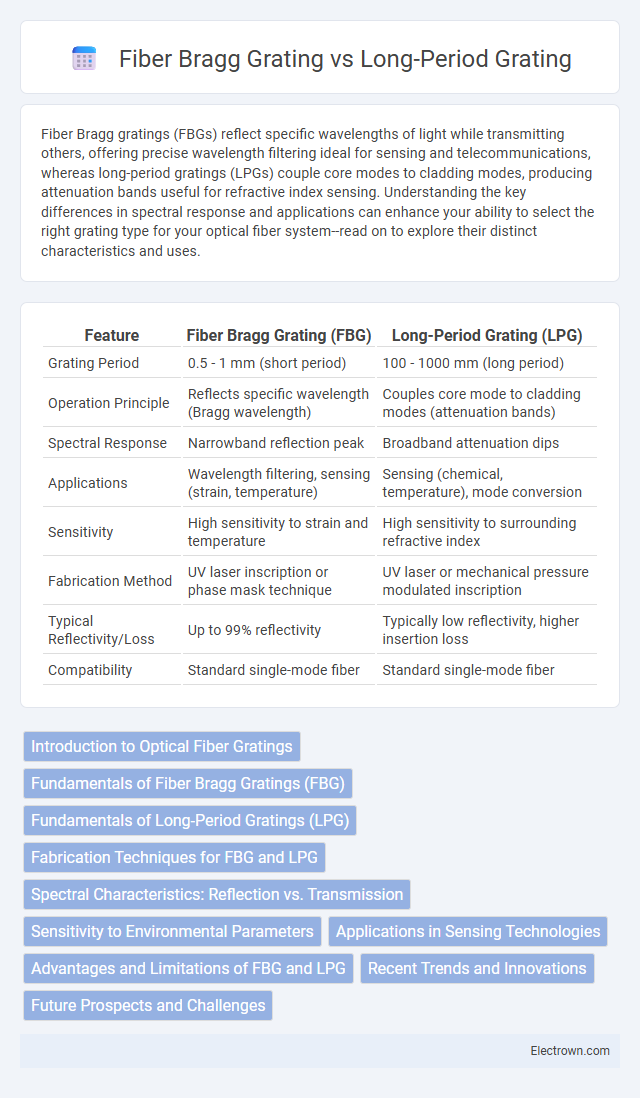

Fiber Bragg gratings (FBGs) reflect specific wavelengths of light while transmitting others, offering precise wavelength filtering ideal for sensing and telecommunications, whereas long-period gratings (LPGs) couple core modes to cladding modes, producing attenuation bands useful for refractive index sensing. Understanding the key differences in spectral response and applications can enhance your ability to select the right grating type for your optical fiber system--read on to explore their distinct characteristics and uses.

Table of Comparison

| Feature | Fiber Bragg Grating (FBG) | Long-Period Grating (LPG) |

|---|---|---|

| Grating Period | 0.5 - 1 mm (short period) | 100 - 1000 mm (long period) |

| Operation Principle | Reflects specific wavelength (Bragg wavelength) | Couples core mode to cladding modes (attenuation bands) |

| Spectral Response | Narrowband reflection peak | Broadband attenuation dips |

| Applications | Wavelength filtering, sensing (strain, temperature) | Sensing (chemical, temperature), mode conversion |

| Sensitivity | High sensitivity to strain and temperature | High sensitivity to surrounding refractive index |

| Fabrication Method | UV laser inscription or phase mask technique | UV laser or mechanical pressure modulated inscription |

| Typical Reflectivity/Loss | Up to 99% reflectivity | Typically low reflectivity, higher insertion loss |

| Compatibility | Standard single-mode fiber | Standard single-mode fiber |

Introduction to Optical Fiber Gratings

Optical fiber gratings are periodic variations in the refractive index along the core of an optical fiber, used to filter specific wavelengths of light. Fiber Bragg gratings (FBGs) reflect particular wavelengths back towards the source, enabling precise wavelength-specific sensing and filtering applications. Long-period gratings (LPGs) couple light from the core to cladding modes over longer periods, offering broad spectral filtering and enhanced sensitivity for your optical fiber sensing systems.

Fundamentals of Fiber Bragg Gratings (FBG)

Fiber Bragg Gratings (FBGs) consist of periodic refractive index variations inscribed along the optical fiber core, reflecting specific wavelengths while transmitting others, based on the Bragg condition. These gratings serve as precise wavelength-selective reflectors, enabling applications in sensing, telecommunications, and signal filtering by measuring shifts in the reflected Bragg wavelength due to strain or temperature changes. Understanding FBG fundamentals helps you optimize their design for high sensitivity and stability, differentiating them from long-period gratings which instead couple core modes to cladding modes and rely on different spectral responses.

Fundamentals of Long-Period Gratings (LPG)

Long-Period Gratings (LPG) consist of periodic refractive index modulations along the fiber core with typical periods ranging from 100 to 1000 micrometers. LPGs couple light from the guided core mode to co-propagating cladding modes, resulting in attenuation bands at specific wavelengths sensitive to external parameters like strain, temperature, and surrounding refractive index. Unlike Fiber Bragg Gratings (FBG) which reflect specific wavelengths, LPGs operate in transmission mode and are widely utilized for sensing and filtering applications due to their high sensitivity and broad tunability.

Fabrication Techniques for FBG and LPG

Fiber Bragg Gratings (FBGs) are typically fabricated using ultraviolet (UV) laser inscription through phase masks, creating periodic refractive index changes in the fiber core with high precision and short grating periods (around 0.5 microns). Long-Period Gratings (LPGs) are produced using methods such as CO2 laser irradiation, electric arc discharge, or mechanical pressure, inducing refractive index modulation over longer periods (100-1000 microns) in the fiber cladding or core-cladding interface. The distinct fabrication techniques result in different grating structures and spectral properties, with FBGs reflecting specific narrow wavelengths and LPGs coupling core modes to cladding modes, affecting broader spectral features.

Spectral Characteristics: Reflection vs. Transmission

Fiber Bragg gratings (FBGs) exhibit sharp reflection spectra at specific wavelengths corresponding to the Bragg condition, allowing precise wavelength filtering and sensing. Long-period gratings (LPGs) show broadband transmission dips due to coupling between core and cladding modes, resulting in wavelength-specific attenuation rather than reflection. The spectral characteristics make FBGs ideal for reflection-based sensing and wavelength multiplexing, while LPGs suit transmission-based applications such as gain flattening and refractive index sensing.

Sensitivity to Environmental Parameters

Fiber Bragg gratings (FBGs) exhibit high sensitivity to strain and temperature changes due to their short grating period that reflects specific wavelengths precisely, making them ideal for precise sensing applications. Long-period gratings (LPGs), with longer grating periods, are more responsive to refractive index variations in the surrounding environment, enhancing their use in chemical and biochemical sensing. The distinct spectral sensitivity of FBGs and LPGs to environmental parameters allows for tailored sensing solutions in structural health monitoring and biochemical analyses.

Applications in Sensing Technologies

Fiber Bragg gratings (FBGs) are extensively used in structural health monitoring, temperature sensing, and strain measurement due to their high sensitivity and wavelength-specific reflectivity. Long-period gratings (LPGs) excel in biochemical sensing and refractive index measurements by leveraging their sensitivity to surrounding media changes and transmission spectrum shifts. Both technologies offer precise, real-time data but differ in spectral response and optimal application environments.

Advantages and Limitations of FBG and LPG

Fiber Bragg gratings (FBG) offer high reflectivity with precise wavelength selectivity, enabling accurate sensing and filtering in telecommunications, but their limited bandwidth can restrict broader spectral applications. Long-period gratings (LPG) provide broader bandwidth and higher sensitivity to surrounding refractive index changes, making them ideal for biochemical and environmental sensing with minimal intrusion on your signal's integrity. While FBGs excel in compact, high-resolution tasks, LPGs accommodate more versatile sensing environments despite typically lower reflectivity and larger device size.

Recent Trends and Innovations

Fiber Bragg gratings (FBGs) and long-period gratings (LPGs) have witnessed significant advancements in sensing applications, with recent trends emphasizing enhanced sensitivity and multiplexing capabilities. Innovations in FBG technology include the development of ultra-short and chirped gratings, which improve strain and temperature resolution, while LPGs have been optimized for refractive index sensing through novel cladding mode coupling techniques. Integration with nanomaterials and machine learning algorithms has further propelled the performance and real-time data analysis of both grating types in structural health monitoring and biochemical detection.

Future Prospects and Challenges

Fiber Bragg gratings (FBGs) offer precise wavelength selectivity and high reflectivity, making them integral to next-generation telecommunication and sensing technologies, while long-period gratings (LPGs) excel in broad spectral filtering and refractive index sensing with potential in biochemical and environmental monitoring. Future prospects for FBGs include enhanced multiplexing capabilities and integration with advanced photonic circuits, yet challenges remain in improving fabrication precision and temperature sensitivity. LPGs face obstacles in achieving higher sensitivity and stability, but advancements in material engineering and hybrid grating designs are expected to extend their applications in wearable sensors and optical signal processing.

Fiber Bragg grating vs Long-period grating Infographic

electrown.com

electrown.com