A light guide plate directs and distributes light evenly from a source, enhancing brightness and efficiency in displays and lighting panels, while a diffuser plate scatters light to reduce glare and create uniform illumination. Discover how choosing between a light guide plate and a diffuser plate can impact Your lighting design by reading the rest of the article.

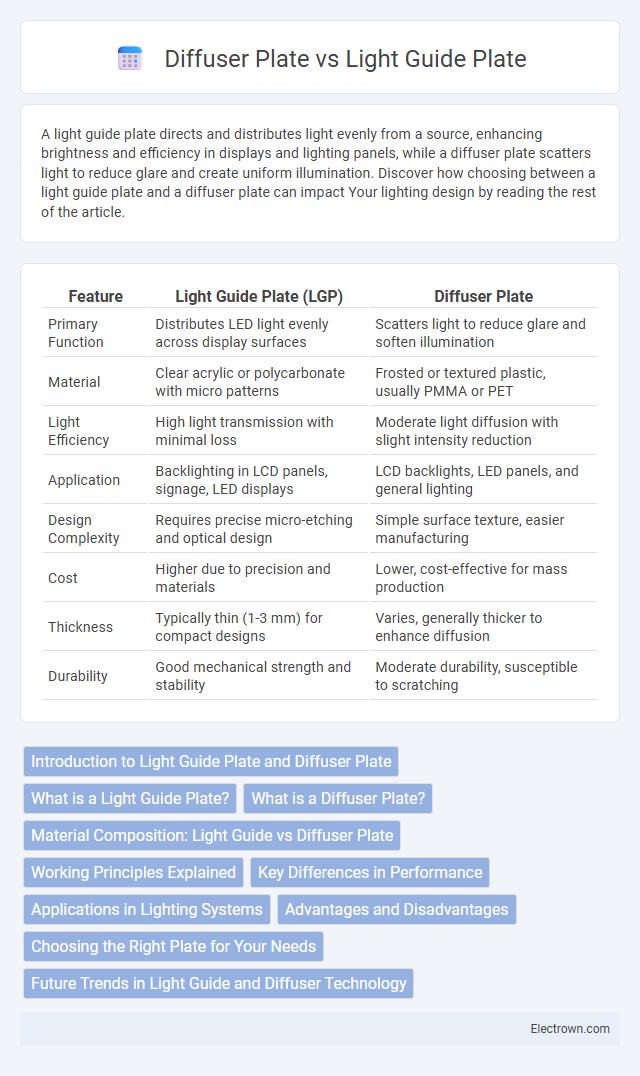

Table of Comparison

| Feature | Light Guide Plate (LGP) | Diffuser Plate |

|---|---|---|

| Primary Function | Distributes LED light evenly across display surfaces | Scatters light to reduce glare and soften illumination |

| Material | Clear acrylic or polycarbonate with micro patterns | Frosted or textured plastic, usually PMMA or PET |

| Light Efficiency | High light transmission with minimal loss | Moderate light diffusion with slight intensity reduction |

| Application | Backlighting in LCD panels, signage, LED displays | LCD backlights, LED panels, and general lighting |

| Design Complexity | Requires precise micro-etching and optical design | Simple surface texture, easier manufacturing |

| Cost | Higher due to precision and materials | Lower, cost-effective for mass production |

| Thickness | Typically thin (1-3 mm) for compact designs | Varies, generally thicker to enhance diffusion |

| Durability | Good mechanical strength and stability | Moderate durability, susceptible to scratching |

Introduction to Light Guide Plate and Diffuser Plate

Light guide plates (LGPs) are optical components designed to evenly distribute light from edge-lit sources, commonly used in displays and LED lighting panels to enhance brightness and uniformity. Diffuser plates scatter light to reduce glare and soften illumination, often positioned after the LGP in lighting assemblies to ensure smooth, consistent light output. Both components work together to improve visual comfort and efficiency in backlit systems.

What is a Light Guide Plate?

A Light Guide Plate (LGP) is a crucial component in LED backlighting systems, designed to distribute light evenly across a display panel. It utilizes microstructures etched or molded on its surface to direct light from LEDs uniformly, enhancing brightness and reducing hotspots. Compared to diffuser plates, LGPs actively manage light direction and intensity, making them essential for achieving high-quality, energy-efficient illumination in devices like LCD TVs and monitors.

What is a Diffuser Plate?

A Diffuser Plate is a transparent or translucent panel designed to evenly disperse light across a surface, reducing glare and hotspots to create uniform illumination. Unlike a Light Guide Plate, which channels light through internal reflection to direct it precisely, a Diffuser Plate scatters light to soften brightness and enhance visual comfort. Commonly used in backlighting applications for LCD displays and LED panels, diffuser plates improve light distribution and image clarity.

Material Composition: Light Guide vs Diffuser Plate

Light guide plates are typically composed of acrylic or polycarbonate materials with high optical clarity to efficiently channel and distribute light through internal reflection. Diffuser plates often use polymethyl methacrylate (PMMA) with added microstructures or surface textures to scatter light uniformly and reduce glare. The distinct material compositions directly influence their functional roles: light guide plates focus on directing light paths, while diffuser plates enhance light diffusion for even illumination.

Working Principles Explained

A Light guide plate (LGP) efficiently channels LED light through embedded patterns, using total internal reflection to direct illumination uniformly across display surfaces. A Diffuser plate, by contrast, scatters light passing through it, enhancing the evenness and reducing glare by diffusing the intensity across a broader area. Understanding these working principles helps you choose the right component to optimize lighting performance in LCD screens or backlight assemblies.

Key Differences in Performance

Light guide plates (LGPs) efficiently channel and distribute light uniformly across displays or lighting panels, enhancing brightness while minimizing energy consumption. Diffuser plates scatter light to reduce glare and soften illumination, but often result in slight light intensity loss compared to LGPs. Performance-wise, LGPs excel in directional brightness and uniformity, whereas diffuser plates prioritize glare reduction and light diffusion quality.

Applications in Lighting Systems

Light guide plates are widely used in backlit displays and LED panels to ensure uniform light distribution and enhance brightness in applications like LCD screens and signage. Diffuser plates are essential in softening and scattering light, reducing glare and shadows, making them ideal for architectural lighting, office environments, and photography studios. Choosing the right component affects your lighting system's efficiency, visual comfort, and overall light quality.

Advantages and Disadvantages

Light guide plates (LGPs) offer precise light distribution and high efficiency in backlighting applications, providing uniform illumination with minimal energy loss. However, they require complex manufacturing processes and can be more expensive compared to diffuser plates. Diffuser plates excel in scattering light to reduce glare and improve viewing angles but may cause slight brightness reduction and less directional control compared to LGPs.

Choosing the Right Plate for Your Needs

Light guide plates efficiently channel light from a source to create uniform brightness, making them ideal for applications requiring precise light distribution like LCD backlighting. Diffuser plates scatter light evenly to reduce glare and soften illumination, perfect for ambient lighting and eye comfort. Choosing the right plate depends on your need for directional uniformity versus diffuse, gentle lighting effects.

Future Trends in Light Guide and Diffuser Technology

Light guide plates are evolving with advanced nanostructures to increase light uniformity and efficiency, while diffuser plates incorporate innovative materials like micro-prism films to enhance brightness and reduce glare. Flexible and ultra-thin designs are becoming prominent, enabling integration in next-generation displays, automotive lighting, and wearable devices. Your choice between these technologies should consider future trends emphasizing energy efficiency, improved optical performance, and miniaturization.

Light guide plate vs Diffuser plate Infographic

electrown.com

electrown.com