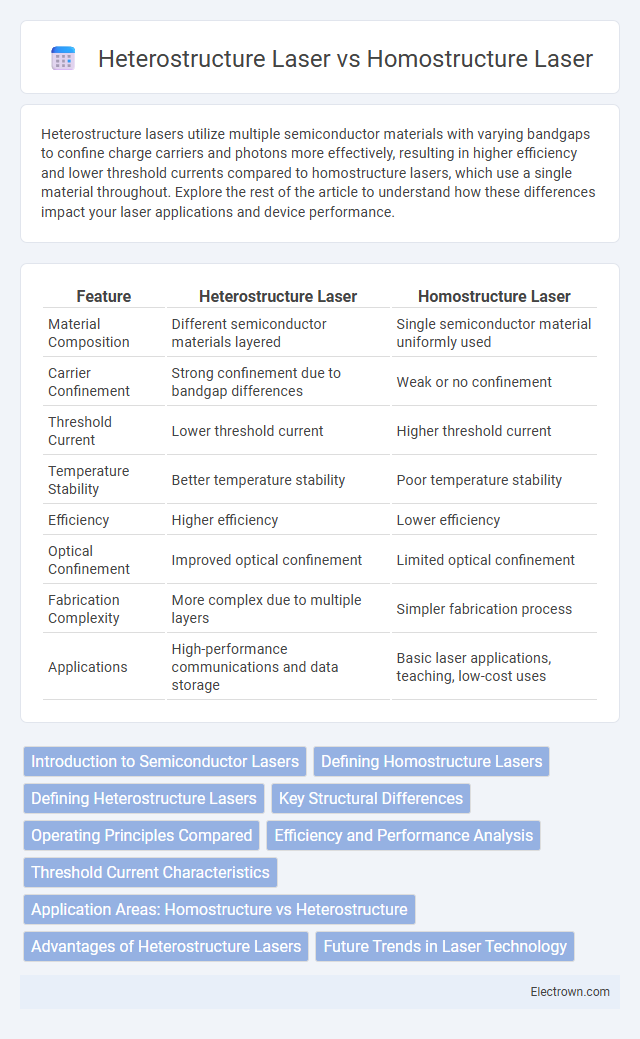

Heterostructure lasers utilize multiple semiconductor materials with varying bandgaps to confine charge carriers and photons more effectively, resulting in higher efficiency and lower threshold currents compared to homostructure lasers, which use a single material throughout. Explore the rest of the article to understand how these differences impact your laser applications and device performance.

Table of Comparison

| Feature | Heterostructure Laser | Homostructure Laser |

|---|---|---|

| Material Composition | Different semiconductor materials layered | Single semiconductor material uniformly used |

| Carrier Confinement | Strong confinement due to bandgap differences | Weak or no confinement |

| Threshold Current | Lower threshold current | Higher threshold current |

| Temperature Stability | Better temperature stability | Poor temperature stability |

| Efficiency | Higher efficiency | Lower efficiency |

| Optical Confinement | Improved optical confinement | Limited optical confinement |

| Fabrication Complexity | More complex due to multiple layers | Simpler fabrication process |

| Applications | High-performance communications and data storage | Basic laser applications, teaching, low-cost uses |

Introduction to Semiconductor Lasers

Semiconductor lasers, essential in optical communication and sensing, are distinguished by their active region structures: heterostructure lasers feature layers of differing semiconductor materials, enhancing electron confinement and efficiency, while homostructure lasers consist of a single semiconductor material, resulting in less effective carrier confinement. Heterostructure lasers offer superior performance due to improved threshold current and temperature stability, making them more suitable for high-speed and high-power applications. Your choice between these laser types impacts device efficiency, spectral purity, and operational reliability in advanced photonics systems.

Defining Homostructure Lasers

Homostructure lasers consist of a single semiconductor material uniformly doped to form the active region, enabling electron-hole recombination for laser emission within a consistent bandgap. They exhibit simpler fabrication but often suffer from lower efficiency and higher threshold currents due to uneven carrier confinement. In contrast, heterostructure lasers utilize multiple materials with varied bandgaps to enhance carrier and optical confinement, resulting in improved performance and reduced threshold currents.

Defining Heterostructure Lasers

Heterostructure lasers utilize layers of different semiconductor materials with varying bandgaps to create a junction that efficiently confines both electrons and photons, enhancing laser performance. Unlike homostructure lasers, which have uniform material composition, heterostructure designs improve carrier injection and reduce threshold current significantly. Your choice of a heterostructure laser can lead to better efficiency, higher output power, and greater temperature stability in optoelectronic applications.

Key Structural Differences

Heterostructure lasers feature multiple semiconductor layers with varying bandgaps, enabling efficient carrier confinement and improved optical performance. Homostructure lasers consist of a single semiconductor material layer, resulting in less effective carrier and photon confinement. The distinct bandgap engineering in heterostructure designs enhances threshold current reduction and laser efficiency compared to the uniform structure of homostructure lasers.

Operating Principles Compared

Heterostructure lasers utilize materials with different bandgap energies to confine both carriers and photons within the active region, enhancing efficiency and threshold current performance. Homostructure lasers consist of a single uniform material, leading to less effective carrier confinement and higher threshold currents. The improved quantum well confinement in heterostructure designs results in superior modulation speed and lower power consumption compared to homostructure lasers.

Efficiency and Performance Analysis

Heterostructure lasers exhibit significantly higher efficiency and performance compared to homostructure lasers due to their superior carrier confinement and reduced threshold current density, which enhances optical gain and reduces energy losses. The heterojunction interface creates a distinct potential well that restricts electron and hole recombination zones, leading to improved output power and spectral purity in laser applications. Your choice of laser technology should consider heterostructure designs for applications demanding high modulation speeds and energy efficiency.

Threshold Current Characteristics

Heterostructure lasers exhibit significantly lower threshold current characteristics compared to homostructure lasers due to better carrier confinement and reduced nonradiative recombination at the active region. This improved efficiency allows your device to operate at lower power levels for lasing action, enhancing overall performance and thermal stability. The heterostructure design confines carriers and photons more effectively, resulting in more efficient stimulated emission and reduced threshold current density.

Application Areas: Homostructure vs Heterostructure

Heterostructure lasers are widely used in high-speed optical communication, data storage, and laser printing due to their superior efficiency, lower threshold current, and enhanced modulation capabilities compared to homostructure lasers. Homostructure lasers find application primarily in basic research and low-cost devices where fabrication simplicity is critical, but their performance limitations restrict their use in advanced telecommunications and integrated photonics. The improved carrier confinement and reduced recombination losses in heterostructure lasers enable their dominance in high-performance applications such as fiber-optic networks and semiconductor laser arrays.

Advantages of Heterostructure Lasers

Heterostructure lasers offer superior performance due to their ability to confine electrons and holes within a narrow active region, resulting in lower threshold currents and higher efficiency compared to homostructure lasers. The bandgap engineering in heterostructures enhances carrier confinement and reduces non-radiative recombination, improving output power and temperature stability. This makes heterostructure lasers ideal for high-speed optical communications and integrated photonic devices.

Future Trends in Laser Technology

Future trends in laser technology emphasize the advancement of heterostructure lasers due to their superior efficiency, lower threshold current, and enhanced modulation speed compared to homostructure lasers. Innovations in material engineering and nanoscale fabrication are enabling heterostructure lasers to achieve higher performance in telecommunications, data storage, and integrated photonic circuits. Continued development in quantum well and quantum dot heterostructures is expected to drive breakthroughs in laser miniaturization and energy efficiency.

Heterostructure laser vs Homostructure laser Infographic

electrown.com

electrown.com