Surface mount LEDs offer a compact design and efficient heat dissipation ideal for modern electronic devices, while through hole LEDs provide stronger mechanical bonds suited for applications requiring durability and easy manual assembly. Explore the rest of the article to understand which LED type best fits Your specific project needs.

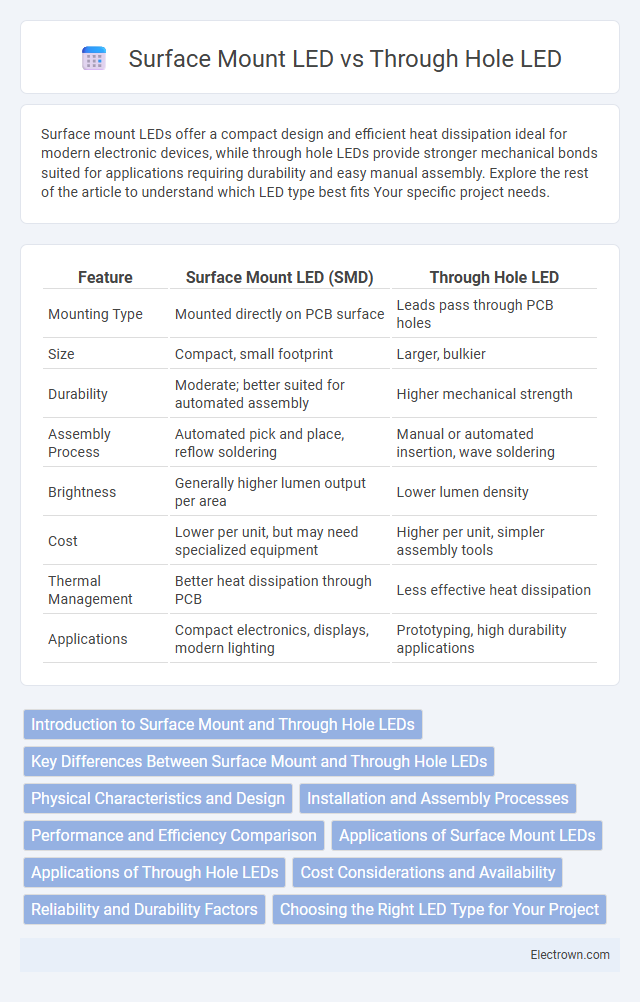

Table of Comparison

| Feature | Surface Mount LED (SMD) | Through Hole LED |

|---|---|---|

| Mounting Type | Mounted directly on PCB surface | Leads pass through PCB holes |

| Size | Compact, small footprint | Larger, bulkier |

| Durability | Moderate; better suited for automated assembly | Higher mechanical strength |

| Assembly Process | Automated pick and place, reflow soldering | Manual or automated insertion, wave soldering |

| Brightness | Generally higher lumen output per area | Lower lumen density |

| Cost | Lower per unit, but may need specialized equipment | Higher per unit, simpler assembly tools |

| Thermal Management | Better heat dissipation through PCB | Less effective heat dissipation |

| Applications | Compact electronics, displays, modern lighting | Prototyping, high durability applications |

Introduction to Surface Mount and Through Hole LEDs

Surface mount LEDs (SMD LEDs) are compact components designed for direct placement on the surface of printed circuit boards, offering high brightness and energy efficiency in a small footprint. Through hole LEDs feature leads that pass through drilled holes on the PCB and are soldered on the opposite side, providing robust mechanical strength and ease of prototype testing. The choice between SMD and through hole LEDs depends on application requirements such as space constraints, manufacturing processes, and reliability needs.

Key Differences Between Surface Mount and Through Hole LEDs

Surface mount LEDs (SMD) are compact, lightweight components soldered directly onto the PCB surface, enabling higher component density and automated assembly processes. Through hole LEDs feature leads that pass through PCB holes, providing stronger mechanical bonds ideal for high-stress environments but limiting miniaturization. Your choice depends on factors like application durability, production volume, and the desired circuit board design complexity.

Physical Characteristics and Design

Surface mount LEDs feature compact, flat packages designed for direct mounting onto PCB surfaces, enabling higher component density and streamlined automated assembly processes. Through hole LEDs possess longer leads that pass through PCB holes, providing robust mechanical support and ease of prototyping or manual soldering. The smaller footprint and low profile of surface mount LEDs make them ideal for modern, space-constrained electronic devices, whereas through hole LEDs are preferred in applications demanding durability against mechanical stress.

Installation and Assembly Processes

Surface mount LEDs (SMD LEDs) enable automated placement and soldering on printed circuit boards (PCBs), significantly increasing assembly speed and precision compared to through hole LEDs, which require manual insertion and wave soldering. The compact design of surface mount LEDs reduces board space and allows for higher component density, optimizing manufacturing efficiency. In contrast, through hole LEDs involve drilling holes into the PCB, adding time-consuming steps that complicate automated assembly lines and limit scalability in mass production.

Performance and Efficiency Comparison

Surface mount LEDs offer higher performance and efficiency due to their compact size and superior heat dissipation capabilities compared to through hole LEDs. The reduced thermal resistance in surface mount LEDs allows for brighter light output and longer lifespan, enhancing your device's overall reliability. Through hole LEDs, while easier to install in prototyping, typically deliver lower luminous efficiency and slower response times.

Applications of Surface Mount LEDs

Surface mount LEDs (SMD LEDs) are widely used in applications requiring compact and highly reliable lighting solutions, such as smartphone backlighting, automotive dashboard displays, and LED strip lights. Their small size and efficient heat dissipation enable high-density circuit board designs, making them ideal for wearable devices, medical instruments, and industrial equipment. You benefit from faster production processes and enhanced durability when choosing surface mount LEDs for advanced electronic applications.

Applications of Through Hole LEDs

Through hole LEDs are ideal for applications requiring robust mechanical strength and durability, such as automotive lighting, industrial equipment, and high-power signal indicators. Their long leads facilitate easy manual soldering and prototyping, making them suitable for DIY electronics and educational projects. You can rely on through hole LEDs for situations where heat dissipation and secure mounting are critical factors.

Cost Considerations and Availability

Surface mount LEDs generally offer lower manufacturing costs due to automated assembly processes and smaller package sizes, which reduce material and labor expenses. Through hole LEDs tend to have higher costs because of manual installation and larger physical footprints, but they remain widely available for prototyping and hobbyist applications. Availability for surface mount LEDs is extensive in commercial electronics, while through hole LEDs are more common in educational kits and legacy designs, influencing cost based on production volume and market demand.

Reliability and Durability Factors

Surface mount LEDs offer superior reliability and durability due to their smaller size and robust solder joints, which resist mechanical stress and thermal cycling better than through hole LEDs. The absence of long leads in surface mount LEDs minimizes the risk of damage from vibration and shock, enhancing their performance in compact and high-vibration applications. Through hole LEDs, while easier to manually assemble and replace, are more susceptible to lead fatigue and solder joint cracking over time, reducing their lifespan under harsh environmental conditions.

Choosing the Right LED Type for Your Project

Surface mount LEDs (SMD) offer a compact design with higher efficiency and better heat dissipation, making them ideal for modern, space-sensitive projects. Through hole LEDs provide robust mechanical strength and easier prototyping, suitable for applications requiring durability and simpler assembly. Choosing the right LED type for your project depends on factors like size constraints, thermal management, and assembly method to ensure optimal performance and reliability.

Surface mount LED vs Through hole LED Infographic

electrown.com

electrown.com