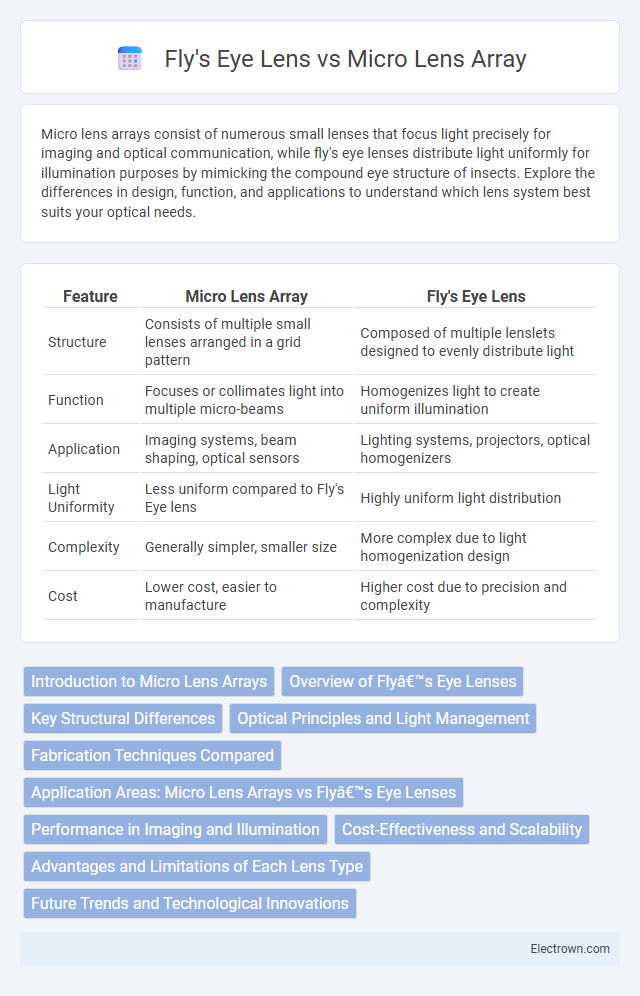

Micro lens arrays consist of numerous small lenses that focus light precisely for imaging and optical communication, while fly's eye lenses distribute light uniformly for illumination purposes by mimicking the compound eye structure of insects. Explore the differences in design, function, and applications to understand which lens system best suits your optical needs.

Table of Comparison

| Feature | Micro Lens Array | Fly's Eye Lens |

|---|---|---|

| Structure | Consists of multiple small lenses arranged in a grid pattern | Composed of multiple lenslets designed to evenly distribute light |

| Function | Focuses or collimates light into multiple micro-beams | Homogenizes light to create uniform illumination |

| Application | Imaging systems, beam shaping, optical sensors | Lighting systems, projectors, optical homogenizers |

| Light Uniformity | Less uniform compared to Fly's Eye lens | Highly uniform light distribution |

| Complexity | Generally simpler, smaller size | More complex due to light homogenization design |

| Cost | Lower cost, easier to manufacture | Higher cost due to precision and complexity |

Introduction to Micro Lens Arrays

Micro lens arrays consist of numerous tiny lenses arranged in a precise grid, optimizing light manipulation and improving image resolution in optical systems. These arrays enhance the uniformity and efficiency of light distribution, making them ideal for applications such as imaging sensors, displays, and laser beam shaping. Your choice between micro lens arrays and Fly's eye lenses depends on the specific optical performance required for uniform light intensity and high spatial resolution.

Overview of Fly’s Eye Lenses

Fly's eye lenses consist of multiple small lenslets arranged in a grid to evenly distribute and homogenize light, commonly used in illumination and imaging systems. Their design enhances uniformity and reduces hotspots, making them ideal for applications requiring consistent light intensity. You can choose fly's eye lenses when precise light shaping and diffusion are critical compared to micro lens arrays, which primarily focus on image resolution and sensing capabilities.

Key Structural Differences

Micro lens arrays consist of numerous smaller lenses arranged in a grid, each focusing light independently, while fly's eye lenses feature a dome-shaped design that spreads light uniformly. The micro lens array structure enables precise light manipulation for imaging and sensing applications, whereas the fly's eye lens excels in light diffusion and homogenization for illumination systems. Your choice between these lenses depends on whether precise focus control or broad light distribution is required.

Optical Principles and Light Management

Micro lens arrays consist of multiple small lenses that focus and collimate light with high precision, improving light uniformity and enhancing image resolution in optical systems. Fly's eye lenses use an array of lenslets to split a beam into several smaller beams, effectively homogenizing light distribution and minimizing hotspots in illumination applications. Both rely on refraction, but micro lens arrays emphasize imaging performance, while fly's eye lenses prioritize light uniformity and beam shaping.

Fabrication Techniques Compared

Micro lens arrays are typically fabricated using techniques such as photolithography, laser direct writing, and thermal reflow, enabling precise control over lens size, shape, and pitch with high uniformity on silicon or glass substrates. Fly's eye lenses often rely on micro-molding, hot embossing, and injection molding methods, facilitating mass production of complex, multi-aperture optical elements with replicated microstructures on polymer materials. The choice between these fabrication techniques affects cost, scalability, optical performance, and application suitability in imaging, illumination, and sensor systems.

Application Areas: Micro Lens Arrays vs Fly’s Eye Lenses

Micro lens arrays are widely used in optical communication, image sensors, and machine vision systems due to their capability to enhance light collection and improve resolution. Fly's eye lenses find applications in illumination engineering, such as uniform light distribution in projectors, LED lighting, and digital light processing (DLP) systems. The choice between micro lens arrays and fly's eye lenses depends on specific application requirements like beam shaping precision, illumination uniformity, and spatial resolution.

Performance in Imaging and Illumination

Micro lens arrays (MLAs) offer superior imaging performance with precise light focusing and minimal aberrations, making them ideal for high-resolution applications such as optical sensors and cameras. Fly's eye lenses, characterized by multiple spherical lenses, excel in uniform illumination distribution by efficiently homogenizing light over larger areas, commonly used in projection and LED lighting systems. While MLAs optimize spatial light modulation and image clarity, fly's eye lenses prioritize even intensity distribution and reduced hot spots for consistent illumination quality.

Cost-Effectiveness and Scalability

Micro lens arrays offer superior cost-effectiveness and scalability due to their simpler fabrication processes and compatibility with mass production techniques like photolithography. Fly's eye lenses, while providing uniform light distribution, often involve more complex assembly and higher manufacturing costs, limiting their scalability for large-scale applications. The ability to produce micro lens arrays on large wafers enhances their economic advantage in volume-driven industries such as imaging and optical communication.

Advantages and Limitations of Each Lens Type

Micro lens arrays offer high resolution and precise light control, making them ideal for imaging systems and optical sensors; however, they can suffer from limited field of view and complex fabrication processes. Fly's eye lenses provide uniform light distribution and enhanced depth of field, beneficial in illumination and projection applications, but they often exhibit lower image quality and reduced focusing ability compared to micro lens arrays. Both lens types balance optical performance with manufacturing complexity, requiring careful selection based on specific application needs.

Future Trends and Technological Innovations

Micro lens arrays are advancing with innovations in nanofabrication and adaptive optics, enabling higher resolution and dynamic focus control for applications in augmented reality and computational imaging. Fly's eye lenses are evolving through integration with micro-electromechanical systems (MEMS) technology, enhancing uniform light distribution and compactness for improved illumination and optical sensing. Future trends indicate a convergence of these technologies, leveraging AI-driven design optimization to create hybrid optical systems with superior imaging performance and energy efficiency.

Micro lens array vs Fly’s eye lens Infographic

electrown.com

electrown.com