Tilted fiber Bragg gratings (TFBGs) differ from standard fiber Bragg gratings (FBGs) by having their grating planes angled relative to the fiber axis, enabling coupling between core and cladding modes for enhanced sensing capabilities. Explore the rest of the article to understand how your choice between TFBG and standard FBG impacts performance in telecommunications and sensing applications.

Table of Comparison

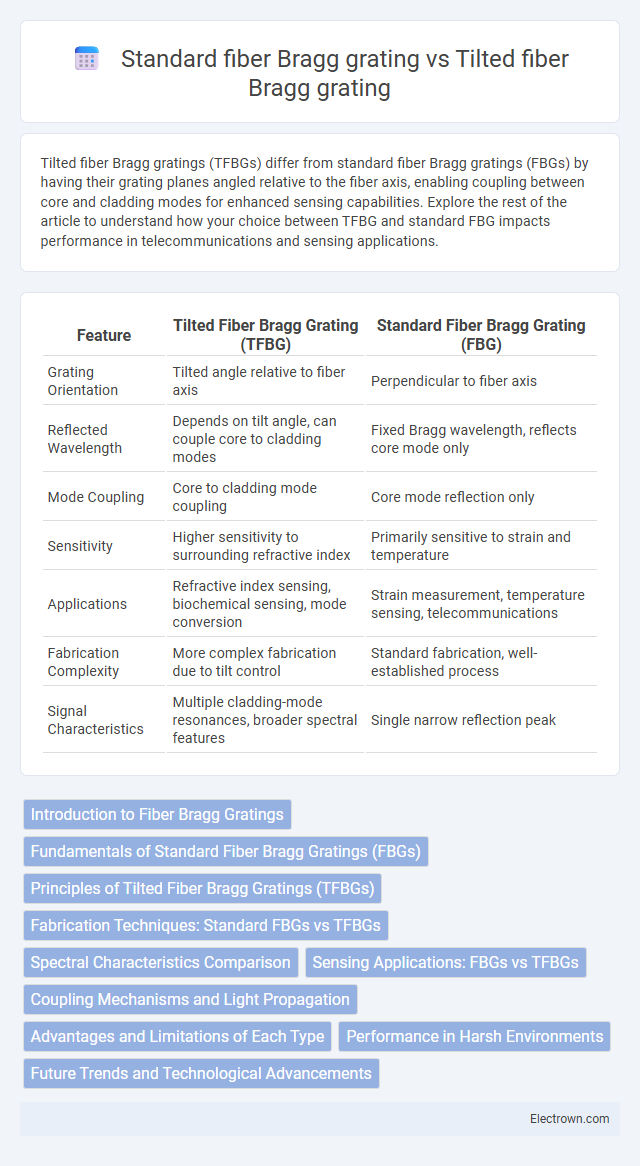

| Feature | Tilted Fiber Bragg Grating (TFBG) | Standard Fiber Bragg Grating (FBG) |

|---|---|---|

| Grating Orientation | Tilted angle relative to fiber axis | Perpendicular to fiber axis |

| Reflected Wavelength | Depends on tilt angle, can couple core to cladding modes | Fixed Bragg wavelength, reflects core mode only |

| Mode Coupling | Core to cladding mode coupling | Core mode reflection only |

| Sensitivity | Higher sensitivity to surrounding refractive index | Primarily sensitive to strain and temperature |

| Applications | Refractive index sensing, biochemical sensing, mode conversion | Strain measurement, temperature sensing, telecommunications |

| Fabrication Complexity | More complex fabrication due to tilt control | Standard fabrication, well-established process |

| Signal Characteristics | Multiple cladding-mode resonances, broader spectral features | Single narrow reflection peak |

Introduction to Fiber Bragg Gratings

Fiber Bragg gratings (FBGs) are optical sensors inscribed within the core of an optical fiber, reflecting specific wavelengths of light while transmitting others. Standard fiber Bragg gratings have perpendicular grating planes to the fiber axis, enabling precise wavelength filtering and sensing applications. Tilted fiber Bragg gratings feature grating planes angled relative to the fiber axis, enhancing coupling between core and cladding modes, making them particularly useful for refractive index sensing and polarization control.

Fundamentals of Standard Fiber Bragg Gratings (FBGs)

Standard Fiber Bragg Gratings (FBGs) consist of periodic variations in the refractive index along the core of an optical fiber, reflecting specific wavelengths of light while transmitting others. Their fundamental operation is based on the Bragg condition, where the grating period determines the reflected wavelength, making them crucial for wavelength filtering and sensing applications. You can leverage the precise wavelength selectivity of standard FBGs for structural health monitoring and telecommunications.

Principles of Tilted Fiber Bragg Gratings (TFBGs)

Tilted Fiber Bragg Gratings (TFBGs) operate by introducing an intentional angle to the grating planes within the fiber core, causing coupling between core modes and cladding modes. This selective mode coupling enables precise control over reflection spectra and enhanced sensitivity to environmental changes such as strain, temperature, and surrounding refractive index. In contrast to standard Fiber Bragg Gratings (FBGs), which reflect light primarily within the core, TFBGs exploit the angle-induced coupling to provide broader sensing capabilities and improved functional versatility.

Fabrication Techniques: Standard FBGs vs TFBGs

Standard fiber Bragg gratings (FBGs) are fabricated using ultraviolet laser inscription through phase masks, creating periodic refractive index variations along the fiber core with a uniform grating plane perpendicular to the fiber axis. Tilted fiber Bragg gratings (TFBGs) employ similar UV laser inscription but require a rotated or specially designed phase mask to introduce an angled grating plane, typically tilted between 2deg and 10deg, which couples core modes to cladding modes. This tilt angle in TFBGs demands precise alignment and control during fabrication to achieve the desired angular grating, significantly influencing spectral and sensing characteristics compared to standard FBGs.

Spectral Characteristics Comparison

Tilted Fiber Bragg Gratings (TFBGs) exhibit broader and more complex spectral characteristics compared to Standard Fiber Bragg Gratings (FBGs), featuring multiple cladding mode resonances alongside the core mode reflection peak. Standard FBGs primarily reflect a narrowband core mode wavelength with high spectral selectivity, ideal for precise wavelength filtering and sensing. TFBGs enable enhanced sensitivity in refractive index sensing and polarization control due to their spectral response involving tilted grating planes that couple light into cladding modes, producing a rich spectral signature.

Sensing Applications: FBGs vs TFBGs

Tilted fiber Bragg gratings (TFBGs) offer enhanced sensitivity for refractive index sensing compared to standard fiber Bragg gratings (FBGs) due to their ability to couple light into cladding modes, which are highly responsive to environmental changes. Standard FBGs primarily detect strain and temperature variations by reflecting specific wavelengths in the core mode, providing reliable measurements but limited to core-guided light interaction. Your choice of grating type should depend on whether high sensitivity to external refractive index changes (favoring TFBGs) or robust strain and temperature sensing (favoring standard FBGs) is critical for your application.

Coupling Mechanisms and Light Propagation

Tilted fiber Bragg gratings (TFBGs) differ from standard fiber Bragg gratings (FBGs) primarily in their coupling mechanisms and light propagation characteristics. Unlike standard FBGs that reflect light in the core mode by coupling forward-propagating core modes to backward-propagating core modes, TFBGs couple core modes to cladding modes due to their grating planes being tilted relative to the fiber axis. This tilt induces efficient coupling of incident light into numerous cladding modes, resulting in distinct spectral features and enhanced sensitivity to external refractive index changes compared to conventional FBGs.

Advantages and Limitations of Each Type

Tilted fiber Bragg gratings (TFBGs) offer enhanced sensitivity to surrounding refractive index changes, making them ideal for sensing applications such as biosensors and environmental monitoring, while standard fiber Bragg gratings (FBGs) primarily enable precise strain and temperature measurements through reflected wavelength shifts. TFBGs exhibit polarization-dependent loss and can couple light into cladding modes, increasing sensing versatility but complicating signal interpretation, whereas standard FBGs provide simpler, stable reflection spectra with lower insertion loss but limited mode interaction. Your choice depends on whether you prioritize complex multi-parameter sensing with TFBGs or straightforward, robust measurements with standard FBGs.

Performance in Harsh Environments

Tilted fiber Bragg gratings (TFBGs) offer enhanced sensitivity and improved strain and temperature discrimination compared to standard fiber Bragg gratings (FBGs), making them ideal for harsh environmental monitoring. Their unique angled structure enables better mode coupling and increased robustness against mechanical and thermal stresses. Your choice of TFBG over standard FBG can significantly improve sensor reliability and longevity in extreme conditions such as high radiation, temperature fluctuations, and corrosive environments.

Future Trends and Technological Advancements

Tilted fiber Bragg gratings (TFBGs) offer enhanced sensitivity and polarization-dependent properties compared to standard fiber Bragg gratings (FBGs), making them ideal for next-generation optical sensing and telecommunications. Emerging technologies focus on integrating TFBGs with advanced materials like graphene and microstructured fibers to improve their selectivity and multiplexing capabilities. Your choice of TFBG devices could leverage these advancements for more precise monitoring in biomedical, environmental, and structural health applications.

Tilted fiber Bragg grating vs Standard fiber Bragg grating Infographic

electrown.com

electrown.com