Edge emitting lasers (EELs) offer high power output and are commonly used in telecommunications and industrial applications, while Vertical-Cavity Surface-Emitting Lasers (VCSELs) provide lower power but higher efficiency and easier integration in optical communication systems. Learn more about how these laser types compare and which one suits your specific needs by reading the full article.

Table of Comparison

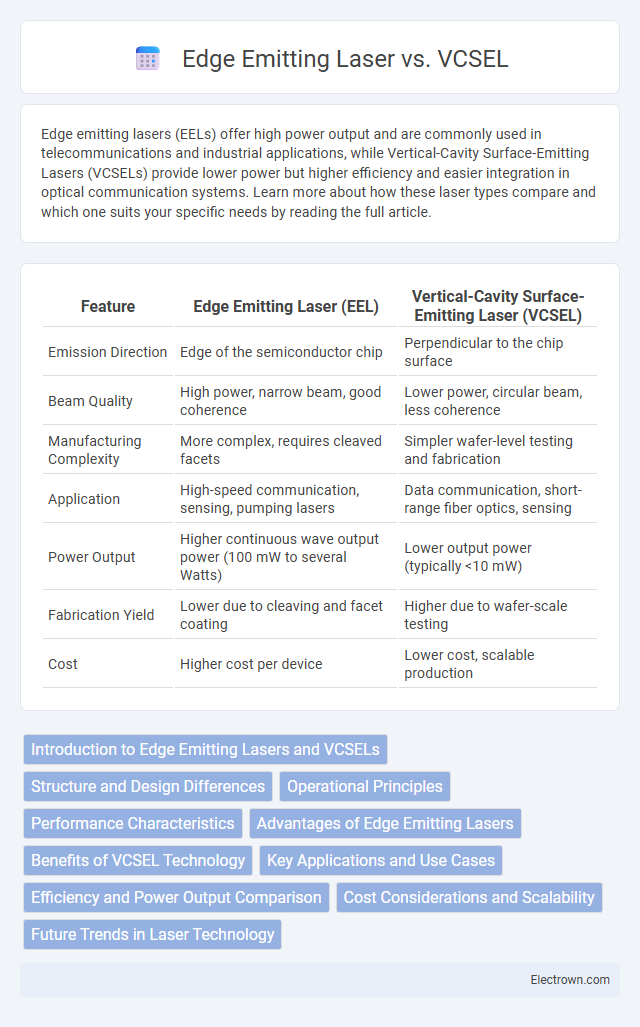

| Feature | Edge Emitting Laser (EEL) | Vertical-Cavity Surface-Emitting Laser (VCSEL) |

|---|---|---|

| Emission Direction | Edge of the semiconductor chip | Perpendicular to the chip surface |

| Beam Quality | High power, narrow beam, good coherence | Lower power, circular beam, less coherence |

| Manufacturing Complexity | More complex, requires cleaved facets | Simpler wafer-level testing and fabrication |

| Application | High-speed communication, sensing, pumping lasers | Data communication, short-range fiber optics, sensing |

| Power Output | Higher continuous wave output power (100 mW to several Watts) | Lower output power (typically <10 mW) |

| Fabrication Yield | Lower due to cleaving and facet coating | Higher due to wafer-scale testing |

| Cost | Higher cost per device | Lower cost, scalable production |

Introduction to Edge Emitting Lasers and VCSELs

Edge emitting lasers (EELs) produce laser light by emitting it from the edge of a semiconductor chip, offering high power output and narrow beam divergence ideal for long-distance fiber optic communication. Vertical-Cavity Surface-Emitting Lasers (VCSELs) emit laser light perpendicular to the chip surface, enabling low-threshold currents, efficient manufacturing, and ease of testing in array configurations for data centers and short-reach applications. Both technologies serve critical roles in optical communication but differ primarily in emission direction, power characteristics, and integration potential.

Structure and Design Differences

Edge emitting lasers (EELs) feature a linear cavity with light emitted from the laser chip's edge, utilizing multiple quantum wells along the waveguide for efficient gain. Vertical-cavity surface-emitting lasers (VCSELs) have a short cavity with light emitted perpendicular to the wafer surface, incorporating distributed Bragg reflector (DBR) mirrors for vertical resonance. The planar VCSEL design enables wafer-scale testing and easy array integration, contrasting with the complex cleaved facet structure required for EELs.

Operational Principles

Edge emitting lasers (EELs) generate light by electrical injection into a semiconductor waveguide, where the laser cavity runs parallel to the wafer surface, allowing the light to emit from the edge of the chip. Vertical-Cavity Surface-Emitting Lasers (VCSELs) operate by reflecting light vertically within the cavity, emitting it perpendicular to the wafer surface through multiple distributed Bragg reflector (DBR) mirrors. EELs typically use a Fabry-Perot cavity design while VCSELs rely on shorter resonant cavities, resulting in distinct emission directions and beam profiles tailored for different applications.

Performance Characteristics

Edge emitting lasers (EELs) offer high output power and narrow spectral linewidth, making them suitable for long-distance communication and high-speed data transmission. Vertical-cavity surface-emitting lasers (VCSELs) provide lower threshold currents, higher modulation bandwidth, and superior beam quality, ideal for short-range optical interconnects and consumer electronics. VCSELs exhibit better temperature stability and easier integration into arrays, while EELs maintain superior wavelength tuning and higher efficiency at high power levels.

Advantages of Edge Emitting Lasers

Edge emitting lasers offer higher output power and superior beam quality compared to VCSELs, making them ideal for long-distance fiber optic communication and high-speed data transmission. Their ability to support multiple wavelengths and higher modulation speeds enhances performance in advanced telecommunications and sensing applications. You benefit from increased efficiency and reliability in demanding environments where precise, high-intensity laser output is critical.

Benefits of VCSEL Technology

VCSEL technology offers benefits such as lower manufacturing costs, higher energy efficiency, and improved beam quality compared to edge-emitting lasers. VCSELs enable easier testing and integration in arrays, enhancing scalability for data communication and sensing applications. Their vertical emission design supports compact packaging and reliable performance in diverse environments.

Key Applications and Use Cases

Edge emitting lasers are widely used in high-speed fiber optic communications due to their ability to deliver higher output power and longer transmission distances, making them ideal for telecommunications and data centers. VCSELs (Vertical-Cavity Surface-Emitting Lasers) excel in short-range applications such as consumer electronics, optical mice, 3D sensing, and LiDAR systems because of their low manufacturing cost, efficient wafer-level testing, and circular beam shape. Your choice between these two laser types depends on the required range, power, and cost considerations for applications like high-speed data links or compact sensing devices.

Efficiency and Power Output Comparison

Edge emitting lasers (EELs) generally offer higher power output compared to vertical-cavity surface-emitting lasers (VCSELs) due to their longer gain region and better heat dissipation capabilities. While VCSELs are more efficient in converting electrical input into light because of their vertical emission and lower threshold currents, EELs excel in applications demanding elevated power levels and higher beam quality. Your choice between these laser types depends on whether efficiency or maximum power output is the priority for your specific optical system.

Cost Considerations and Scalability

Edge emitting lasers generally incur higher manufacturing costs due to complex fabrication processes such as cleaved facets and precise cavity alignment, impacting scalability for mass production. In contrast, VCSELs benefit from wafer-scale fabrication techniques that enable lower per-unit costs and enhanced scalability, making them ideal for high-volume applications. Cost efficiency and scalability advantages of VCSELs stem from their planar structure, compatibility with standard semiconductor processing, and ease of testing at the wafer level.

Future Trends in Laser Technology

Edge emitting lasers (EELs) continue to dominate high-power applications due to their superior output power and wavelength versatility, while vertical-cavity surface-emitting lasers (VCSELs) gain traction in short-reach data communications and sensing owing to their low manufacturing costs and ease of integration. Future trends emphasize the development of hybrid laser structures combining EEL and VCSEL advantages, aiming to enhance modulation speeds and energy efficiency for emerging 5G/6G networks and LiDAR technologies. Advances in photonic integration and novel semiconductor materials like gallium nitride (GaN) and indium phosphide (InP) are expected to further boost performance and reduce costs for both laser types.

Edge emitting laser vs VCSEL Infographic

electrown.com

electrown.com