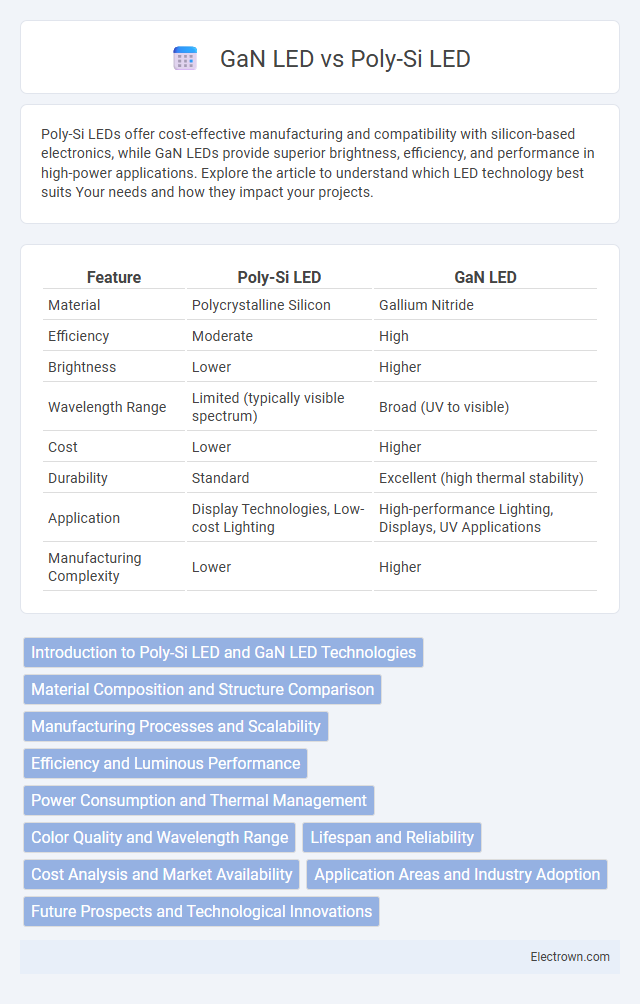

Poly-Si LEDs offer cost-effective manufacturing and compatibility with silicon-based electronics, while GaN LEDs provide superior brightness, efficiency, and performance in high-power applications. Explore the article to understand which LED technology best suits Your needs and how they impact your projects.

Table of Comparison

| Feature | Poly-Si LED | GaN LED |

|---|---|---|

| Material | Polycrystalline Silicon | Gallium Nitride |

| Efficiency | Moderate | High |

| Brightness | Lower | Higher |

| Wavelength Range | Limited (typically visible spectrum) | Broad (UV to visible) |

| Cost | Lower | Higher |

| Durability | Standard | Excellent (high thermal stability) |

| Application | Display Technologies, Low-cost Lighting | High-performance Lighting, Displays, UV Applications |

| Manufacturing Complexity | Lower | Higher |

Introduction to Poly-Si LED and GaN LED Technologies

Poly-Si LED technology utilizes polycrystalline silicon as the semiconductor material, offering cost-effective fabrication and compatibility with existing silicon-based electronics. GaN LED technology, based on gallium nitride semiconductors, delivers superior efficiency, higher brightness, and excellent thermal stability, making it ideal for high-performance lighting applications. Comparing these technologies highlights Poly-Si LEDs as suitable for low-cost, large-area displays, while GaN LEDs excel in energy-efficient, high-intensity illumination.

Material Composition and Structure Comparison

Poly-Si LEDs consist of polysilicon as the semiconductor material, characterized by a polycrystalline structure with grain boundaries that affect electron mobility and overall performance. GaN LEDs utilize gallium nitride, a wide bandgap semiconductor with a single-crystal structure that enables higher efficiency, greater brightness, and better thermal stability. Your choice between Poly-Si and GaN LEDs depends on specific application requirements, as GaN LEDs generally outperform Poly-Si LEDs in luminous efficiency and durability.

Manufacturing Processes and Scalability

Poly-Si LED fabrication involves depositing polysilicon layers on substrates, leveraging established low-cost CMOS-compatible processes that enable integration with existing silicon-based electronics, enhancing scalability for high-volume production. In contrast, GaN LED manufacturing requires epitaxial growth on sapphire or silicon carbide substrates through complex metal-organic chemical vapor deposition (MOCVD), which presents higher material costs and challenges in wafer uniformity that impact large-scale scalability. Poly-Si LEDs benefit from simpler, more scalable deposition techniques, while GaN LEDs offer superior performance at the expense of more intricate and expensive manufacturing processes.

Efficiency and Luminous Performance

GaN LEDs exhibit higher efficiency and luminous performance compared to Poly-Si LEDs due to their superior material properties, including a wider bandgap and higher electron mobility, which enable better light emission and lower power consumption. Poly-Si LEDs generally have lower luminous efficacy and brightness, as their polysilicon structure causes more defects and non-radiative recombination, reducing overall efficiency. GaN LEDs achieve luminous efficacies exceeding 150 lm/W, while Poly-Si LEDs typically lag behind in the range of 10-30 lm/W, making GaN the preferred choice for high-performance lighting applications.

Power Consumption and Thermal Management

Poly-Si LEDs typically exhibit higher power consumption due to increased electrical resistance in polycrystalline silicon layers, while GaN LEDs offer superior energy efficiency with lower forward voltage and higher luminous efficacy. Thermal management is more challenging in Poly-Si LEDs because of less efficient heat dissipation and lower thermal conductivity, whereas GaN LEDs benefit from better thermal stability and performance, enabling improved heat dissipation through substrates like sapphire or silicon carbide. These factors make GaN LEDs more suitable for high-power applications requiring efficient energy use and effective thermal regulation.

Color Quality and Wavelength Range

Poly-Si LEDs typically emit light with limited color quality and a narrower wavelength range, predominantly in the visible spectrum around red and amber hues, due to silicon's indirect bandgap properties. GaN LEDs excel in color quality by producing highly saturated, pure colors, especially in the blue to ultraviolet wavelength range (approximately 365-480 nm), benefiting from the direct wide bandgap of gallium nitride. This intrinsic material advantage allows GaN LEDs to achieve superior brightness, color rendering index (CRI), and broader application in full-spectrum lighting and displays.

Lifespan and Reliability

Poly-Si LEDs typically demonstrate moderate lifespan due to polycrystalline silicon's susceptibility to grain boundary defects, which can lead to degradation under prolonged operation. GaN LEDs exhibit superior reliability and extended lifespan, often exceeding 50,000 hours, attributed to GaN's wide bandgap and robust thermal stability that minimize defect formation and improve performance consistency. The inherent material properties of GaN make it the preferred choice for applications demanding high durability and long-term efficiency.

Cost Analysis and Market Availability

Poly-Si LEDs offer lower production costs due to their compatibility with existing silicon manufacturing infrastructure, making them attractive for large-scale and cost-sensitive applications. GaN LEDs, although more expensive to produce because of complex substrate requirements, dominate the high-performance market with superior efficiency and brightness. Market availability favors GaN LEDs in premium segments like automotive lighting and displays, while Poly-Si LEDs are gaining ground in cost-driven sectors such as general lighting and flexible electronics.

Application Areas and Industry Adoption

Poly-Si LEDs are predominantly utilized in flexible displays, wearable technology, and low-power integrated optoelectronics due to their compatibility with silicon-based CMOS processes and cost-effective manufacturing. GaN LEDs dominate in high-brightness applications such as automotive lighting, general illumination, and ultraviolet sterilization, driven by their superior efficiency and high thermal stability. Industry adoption reflects these strengths, with Poly-Si LEDs favored in consumer electronics and GaN LEDs leading in industrial, automotive, and large-scale lighting markets.

Future Prospects and Technological Innovations

Poly-Si LEDs offer cost advantages and easier integration with existing silicon-based electronics, promising scalable applications in flexible and large-area displays. GaN LEDs lead in efficiency and brightness, driving innovations in high-performance lighting, UV devices, and power electronics. Future prospects include hybrid approaches leveraging Poly-Si's manufacturability and GaN's superior optical properties to enable next-generation optoelectronic systems.

Poly-Si LED vs GaN LED Infographic

electrown.com

electrown.com