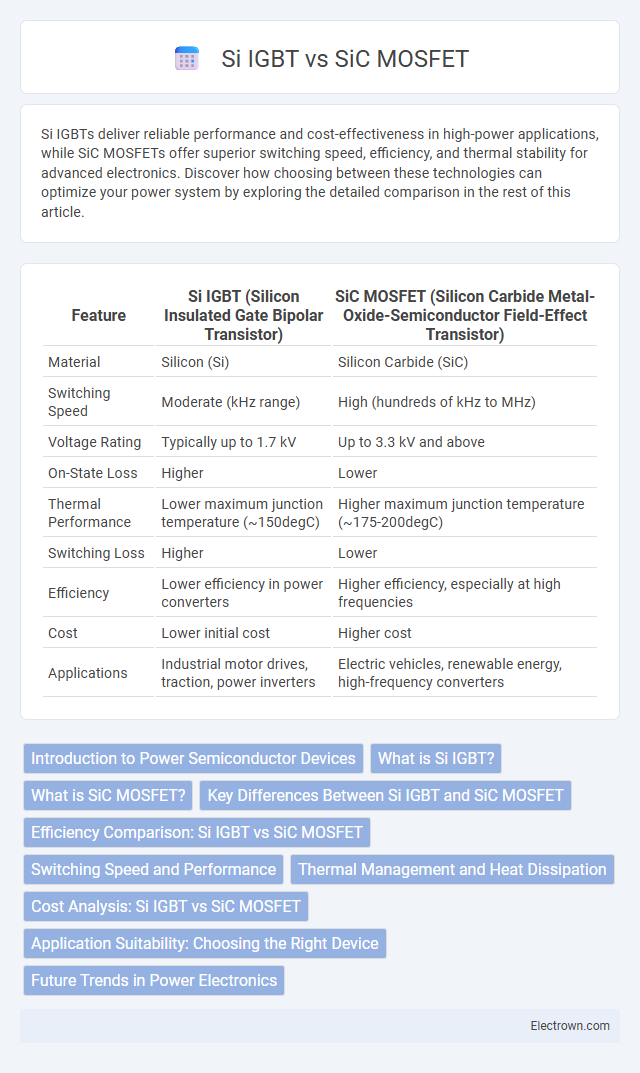

Si IGBTs deliver reliable performance and cost-effectiveness in high-power applications, while SiC MOSFETs offer superior switching speed, efficiency, and thermal stability for advanced electronics. Discover how choosing between these technologies can optimize your power system by exploring the detailed comparison in the rest of this article.

Table of Comparison

| Feature | Si IGBT (Silicon Insulated Gate Bipolar Transistor) | SiC MOSFET (Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistor) |

|---|---|---|

| Material | Silicon (Si) | Silicon Carbide (SiC) |

| Switching Speed | Moderate (kHz range) | High (hundreds of kHz to MHz) |

| Voltage Rating | Typically up to 1.7 kV | Up to 3.3 kV and above |

| On-State Loss | Higher | Lower |

| Thermal Performance | Lower maximum junction temperature (~150degC) | Higher maximum junction temperature (~175-200degC) |

| Switching Loss | Higher | Lower |

| Efficiency | Lower efficiency in power converters | Higher efficiency, especially at high frequencies |

| Cost | Lower initial cost | Higher cost |

| Applications | Industrial motor drives, traction, power inverters | Electric vehicles, renewable energy, high-frequency converters |

Introduction to Power Semiconductor Devices

Silicon IGBTs (Insulated Gate Bipolar Transistors) and Silicon Carbide MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) are essential power semiconductor devices used in high-efficiency energy conversion. Si IGBTs excel in handling high voltage and current in applications like industrial motor drives, while SiC MOSFETs offer faster switching speeds, lower losses, and higher temperature tolerance suitable for advanced electric vehicles and renewable energy systems. Understanding these devices helps optimize your power electronics designs for performance and reliability.

What is Si IGBT?

Si IGBT (Silicon Insulated Gate Bipolar Transistor) is a semiconductor device that combines the high input impedance of a MOSFET with the low on-state power loss of a bipolar transistor. It is widely used in high-power applications such as motor drives, inverters, and power grids due to its efficient switching and conduction capabilities. Choosing Si IGBT can optimize Your system's performance where moderate switching speed and high voltage handling are essential.

What is SiC MOSFET?

SiC MOSFET, or Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistor, is a semiconductor device designed for high-efficiency power switching applications. It offers superior performance over traditional Si IGBTs (Silicon Insulated-Gate Bipolar Transistors) by enabling faster switching speeds, higher temperature tolerance, and lower conduction losses. This makes SiC MOSFETs ideal for electric vehicles, renewable energy systems, and industrial power converters where energy efficiency and thermal management are critical.

Key Differences Between Si IGBT and SiC MOSFET

Si IGBTs (Silicon Insulated Gate Bipolar Transistors) feature slower switching speeds and higher conduction losses compared to SiC MOSFETs (Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistors), which provide superior efficiency and thermal conductivity. SiC MOSFETs operate at higher voltages and temperatures, making them ideal for high-power, high-frequency applications, whereas Si IGBTs excel in lower frequency, high-current scenarios due to their robust design. The wide bandgap technology of SiC MOSFETs enables lower switching losses and faster response times, significantly improving power density and reducing system size.

Efficiency Comparison: Si IGBT vs SiC MOSFET

SiC MOSFETs demonstrate superior efficiency over Si IGBTs due to lower on-resistance and faster switching speeds, resulting in reduced conduction and switching losses. The wide-bandgap properties of SiC enable higher temperature operation and improved thermal conductivity, enhancing overall system efficiency in power electronics. This efficiency advantage is particularly significant in applications such as electric vehicles and renewable energy inverters where power density and energy savings are critical.

Switching Speed and Performance

Si IGBTs typically exhibit slower switching speeds due to their bipolar conduction mechanism, which results in higher switching losses compared to SiC MOSFETs. SiC MOSFETs leverage a unipolar conduction mode, enabling faster switching frequencies up to several hundred kHz with significantly lower switching losses and reduced thermal stress. The superior switching performance of SiC MOSFETs makes them ideal for high-frequency applications requiring efficient power conversion and enhanced system reliability.

Thermal Management and Heat Dissipation

Si IGBTs typically exhibit higher junction temperatures and require larger heat sinks due to greater power losses compared to SiC MOSFETs, which boast superior thermal conductivity and lower thermal resistance. SiC MOSFETs can operate efficiently at higher temperatures, reducing the size and complexity of your thermal management system while enhancing reliability. Effective heat dissipation in SiC devices leads to improved performance in high-power and high-frequency applications, making them ideal for thermal-sensitive environments.

Cost Analysis: Si IGBT vs SiC MOSFET

Silicon IGBTs generally offer lower upfront costs compared to SiC MOSFETs due to mature manufacturing processes and widespread availability. However, SiC MOSFETs provide greater efficiency and reduced energy losses, which can lead to lower operational expenses and total cost of ownership over time. Your choice should balance initial investment against long-term benefits, especially in high-performance or energy-sensitive applications.

Application Suitability: Choosing the Right Device

Si IGBTs excel in high-voltage and high-current applications such as industrial motor drives, power inverters, and traction systems due to their robust switching capabilities and cost-effectiveness. SiC MOSFETs offer superior efficiency, faster switching speeds, and higher temperature tolerance, making them ideal for applications like electric vehicles, renewable energy converters, and aerospace systems where performance and thermal management are critical. Your choice depends on balancing cost, efficiency, and operational demands to ensure optimal device performance in your specific application.

Future Trends in Power Electronics

Si IGBTs continue to dominate high-power applications due to their cost-effectiveness and mature technology, but SiC MOSFETs are rapidly gaining traction because of their superior efficiency, higher switching frequencies, and better thermal performance. Future trends in power electronics point towards increased adoption of SiC MOSFETs in electric vehicles, renewable energy systems, and smart grids, driven by their ability to reduce energy losses and improve system reliability. Research and development efforts focus on lowering production costs and enhancing device robustness to accelerate SiC MOSFET integration in next-generation power electronics.

si igbt vs sic mosfet Infographic

electrown.com

electrown.com