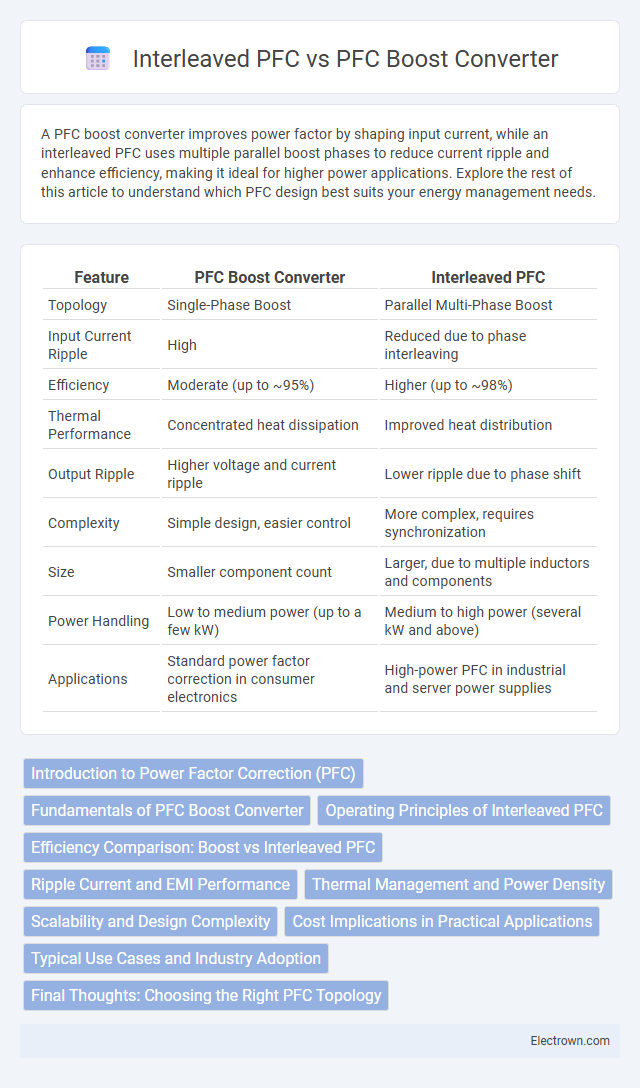

A PFC boost converter improves power factor by shaping input current, while an interleaved PFC uses multiple parallel boost phases to reduce current ripple and enhance efficiency, making it ideal for higher power applications. Explore the rest of this article to understand which PFC design best suits your energy management needs.

Table of Comparison

| Feature | PFC Boost Converter | Interleaved PFC |

|---|---|---|

| Topology | Single-Phase Boost | Parallel Multi-Phase Boost |

| Input Current Ripple | High | Reduced due to phase interleaving |

| Efficiency | Moderate (up to ~95%) | Higher (up to ~98%) |

| Thermal Performance | Concentrated heat dissipation | Improved heat distribution |

| Output Ripple | Higher voltage and current ripple | Lower ripple due to phase shift |

| Complexity | Simple design, easier control | More complex, requires synchronization |

| Size | Smaller component count | Larger, due to multiple inductors and components |

| Power Handling | Low to medium power (up to a few kW) | Medium to high power (several kW and above) |

| Applications | Standard power factor correction in consumer electronics | High-power PFC in industrial and server power supplies |

Introduction to Power Factor Correction (PFC)

Power Factor Correction (PFC) improves the efficiency of power delivery by minimizing reactive power and harmonics in electrical systems. A single-phase boost converter is the most common PFC topology, providing continuous input current and high power factor with a simple control strategy. Interleaved PFC, using multiple boost phases operating out of phase, enhances current ripple reduction and thermal management, making it suitable for higher power applications and improving your system's overall performance.

Fundamentals of PFC Boost Converter

A PFC boost converter improves power quality by increasing power factor and reducing harmonic distortion in electrical systems. It operates by stepping up voltage and regulating input current to be sinusoidal and in phase with the input voltage. Your choice between a standard PFC boost converter and an interleaved design depends on factors like efficiency, current ripple reduction, and thermal performance.

Operating Principles of Interleaved PFC

Interleaved PFC operates by connecting multiple boost converter stages in parallel, each phase switching at the same frequency but with phase shifts to reduce input current ripple and improve efficiency. This configuration allows better power distribution and thermal management, enhancing overall performance compared to a single-stage PFC boost converter. Your power system benefits from lower electromagnetic interference and improved power factor correction under varying load conditions.

Efficiency Comparison: Boost vs Interleaved PFC

Interleaved PFC converters typically achieve higher efficiency than single boost PFC converters by reducing conduction and switching losses through current sharing and lower ripple current. The parallel operation in interleaved PFC reduces thermal stress on components, improving reliability and enabling smaller heat sinks. Boost PFCs, while simpler and cost-effective, may have lower efficiency under high load conditions due to increased stress and losses in a single switching path.

Ripple Current and EMI Performance

Interleaved PFC boost converters significantly reduce ripple current by splitting the input current across multiple phases, resulting in lower current stress on each component and improved overall efficiency. This multi-phase operation also enhances EMI performance due to the phase-shifted switching that cancels out harmonics and spreads the frequency spectrum, minimizing electromagnetic interference. Choosing an interleaved design can optimize Your power supply's ripple and EMI, ensuring better compliance with strict regulatory standards.

Thermal Management and Power Density

Interleaved PFC converters offer superior thermal management by distributing current across multiple phases, reducing individual component stress and enhancing heat dissipation compared to single-phase PFC boost converters. This parallel architecture enables higher power density by minimizing magnetic component size and optimizing PCB layout, resulting in compact designs with improved efficiency. Consequently, interleaved PFCs are preferred in applications demanding stringent thermal performance and space constraints.

Scalability and Design Complexity

Interleaved PFC boost converters offer improved scalability compared to single-phase PFC boost designs by distributing current across multiple phases, reducing overall stress on each component and enabling higher power levels. The design complexity of interleaved PFC systems is notably higher due to the need for precise phase-shift control, synchronization, and current balancing between phases. Conversely, single-phase PFC boost converters feature simpler control schemes and fewer components, making them easier to design but less effective for high-power or highly scalable applications.

Cost Implications in Practical Applications

PFC boost converters generally have lower upfront costs due to simpler circuit designs and fewer components, which benefits small to medium power applications. Interleaved PFC converters, while more expensive initially due to multiple inductors and control complexity, offer improved efficiency and reduced thermal stress, leading to lower long-term operational costs in high-power systems. Selecting between the two requires balancing initial investment against efficiency gains and reliability in practical power factor correction scenarios.

Typical Use Cases and Industry Adoption

PFC boost converters are widely used in single-phase power supplies for consumer electronics and LED drivers due to their simplicity and efficiency in improving power factor. Interleaved PFC converters find typical applications in high-power industrial equipment and server power supplies, offering enhanced thermal management and reduced input current ripple. Your choice depends on power requirements and space constraints, with interleaved designs favored in demanding, high-current environments for greater performance and reliability.

Final Thoughts: Choosing the Right PFC Topology

Selecting the ideal PFC topology depends on your application's power requirements and efficiency targets. A single-phase PFC boost converter offers simplicity and cost-effectiveness for lower power levels but may struggle with thermal management and electromagnetic interference at higher currents. Interleaved PFC designs provide improved current handling, reduced input ripple, and enhanced efficiency, making them suitable for high-power systems demanding reliable power quality.

pfc boost converter vs interleaved pfc Infographic

electrown.com

electrown.com