Buck converters efficiently step down voltage while boost converters increase voltage, each serving distinct roles in power management systems. Explore the rest of the article to understand which converter suits your specific application needs.

Table of Comparison

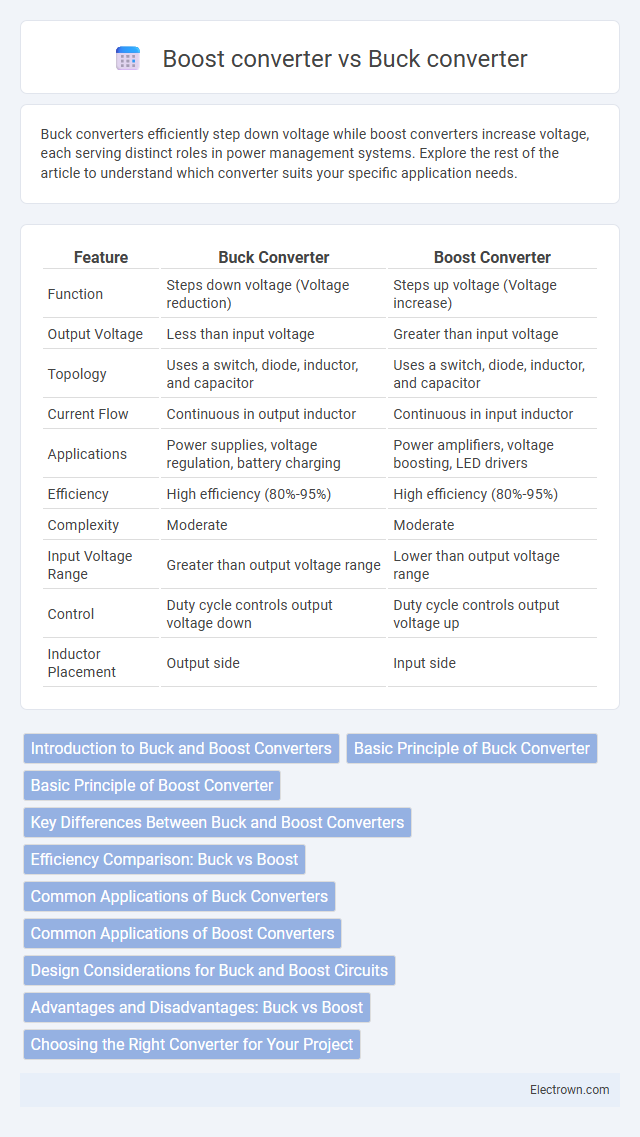

| Feature | Buck Converter | Boost Converter |

|---|---|---|

| Function | Steps down voltage (Voltage reduction) | Steps up voltage (Voltage increase) |

| Output Voltage | Less than input voltage | Greater than input voltage |

| Topology | Uses a switch, diode, inductor, and capacitor | Uses a switch, diode, inductor, and capacitor |

| Current Flow | Continuous in output inductor | Continuous in input inductor |

| Applications | Power supplies, voltage regulation, battery charging | Power amplifiers, voltage boosting, LED drivers |

| Efficiency | High efficiency (80%-95%) | High efficiency (80%-95%) |

| Complexity | Moderate | Moderate |

| Input Voltage Range | Greater than output voltage range | Lower than output voltage range |

| Control | Duty cycle controls output voltage down | Duty cycle controls output voltage up |

| Inductor Placement | Output side | Input side |

Introduction to Buck and Boost Converters

Buck converters efficiently step down voltage from a higher input to a lower output, making them ideal for applications requiring power regulation with minimal energy loss. Boost converters, on the other hand, increase voltage from a lower input to a higher output, widely used in battery-powered devices to achieve necessary voltage levels. Understanding your power requirements helps determine whether a buck or boost converter best suits your electronic design for optimal performance and efficiency.

Basic Principle of Buck Converter

A Buck converter operates by switching its transistor on and off to step down voltage efficiently, using an inductor and a diode to maintain continuous current flow. This regulator converts a higher input voltage to a lower output voltage while minimizing power losses and maintaining high efficiency. Understanding the Buck converter's principle helps you design power supplies that require stable, reduced voltages for your electronic circuits.

Basic Principle of Boost Converter

A boost converter operates by storing energy in an inductor during the switch-on phase and releasing it to the output through a diode during the switch-off phase, effectively increasing the voltage. The inductor current ramps up when the switch is closed, and when opened, the energy is transferred to the load and output capacitor, resulting in a voltage higher than the input source. This step-up conversion principle distinguishes the boost converter from buck converters, which reduce voltage instead of increasing it.

Key Differences Between Buck and Boost Converters

Buck converters step down voltage from a higher input to a lower output, while boost converters increase voltage from a lower input to a higher output. Buck converters typically exhibit higher efficiency in voltage reduction applications, whereas boost converters are optimized for scenarios requiring voltage elevation with stable current. The distinct operational modes and component arrangements, including inductor, switch, diode, and capacitor configurations, fundamentally differentiate their performance characteristics and suitable use cases.

Efficiency Comparison: Buck vs Boost

Buck converters typically achieve higher efficiency than boost converters when stepping down voltage due to lower switching losses and simpler topologies that minimize energy dissipation. Boost converters often face increased conduction losses and stress on components when stepping up voltage, which can reduce overall efficiency under heavy load conditions. Understanding these differences helps you select the optimal converter type for your power management needs, balancing efficiency with voltage requirements.

Common Applications of Buck Converters

Buck converters are commonly used in power supply systems for efficient voltage step-down in devices such as laptops, LED drivers, and battery-powered electronics. Their ability to provide regulated lower voltage output from higher voltage sources makes them ideal for applications requiring stable power delivery and energy conservation. You can rely on buck converters to optimize performance in automotive electronics and renewable energy systems where voltage stability is crucial.

Common Applications of Boost Converters

Boost converters are commonly used in applications requiring voltage step-up from a lower input voltage, such as battery-powered devices, solar power systems, and electric vehicles. Your portable electronics benefit from boost converters to maintain stable output voltage despite fluctuating battery levels. These converters also play a key role in LED drivers, power supply modules, and renewable energy systems where efficient voltage regulation is critical.

Design Considerations for Buck and Boost Circuits

Buck converter design prioritizes efficient step-down voltage regulation, focusing on selecting appropriate inductor values, switching frequency, and duty cycle to minimize voltage ripple and optimize current handling. Boost converter design emphasizes stable step-up voltage control, requiring careful consideration of diode recovery time, inductor saturation, and input voltage range to prevent instability and ensure continuous conduction mode. Both converter types demand thorough thermal management and component stress analysis to enhance reliability in power supply applications.

Advantages and Disadvantages: Buck vs Boost

Buck converters offer high efficiency by stepping down voltage with minimal energy loss, making them ideal for low-voltage applications, but they cannot increase voltage above the input level. Boost converters are advantageous in providing voltage step-up capability, essential for battery-powered devices requiring higher voltages, though they may introduce higher current stress and efficiency losses. Both converters have trade-offs in complexity, electromagnetic interference, and cost, which impact their suitability depending on specific power supply requirements.

Choosing the Right Converter for Your Project

Choosing between a Buck converter and a Boost converter depends primarily on your project's voltage requirements. Buck converters efficiently step down voltage from a higher input to a lower output, ideal for powering low-voltage devices from a higher voltage source. If your project needs to increase voltage from a lower input to a higher output, a Boost converter is the optimal choice, ensuring stable power delivery and efficient energy conversion.

Buck converter vs Boost converter Infographic

electrown.com

electrown.com