Sinusoidal PWM produces a pure sine wave output by modulating the carrier frequency with a sinusoidal reference, while Third Harmonic Injection PWM enhances the output voltage by adding a third harmonic component, effectively increasing the fundamental voltage without exceeding the DC bus limits. Discover how these two PWM techniques impact your power conversion efficiency and harmonic performance in the rest of the article.

Table of Comparison

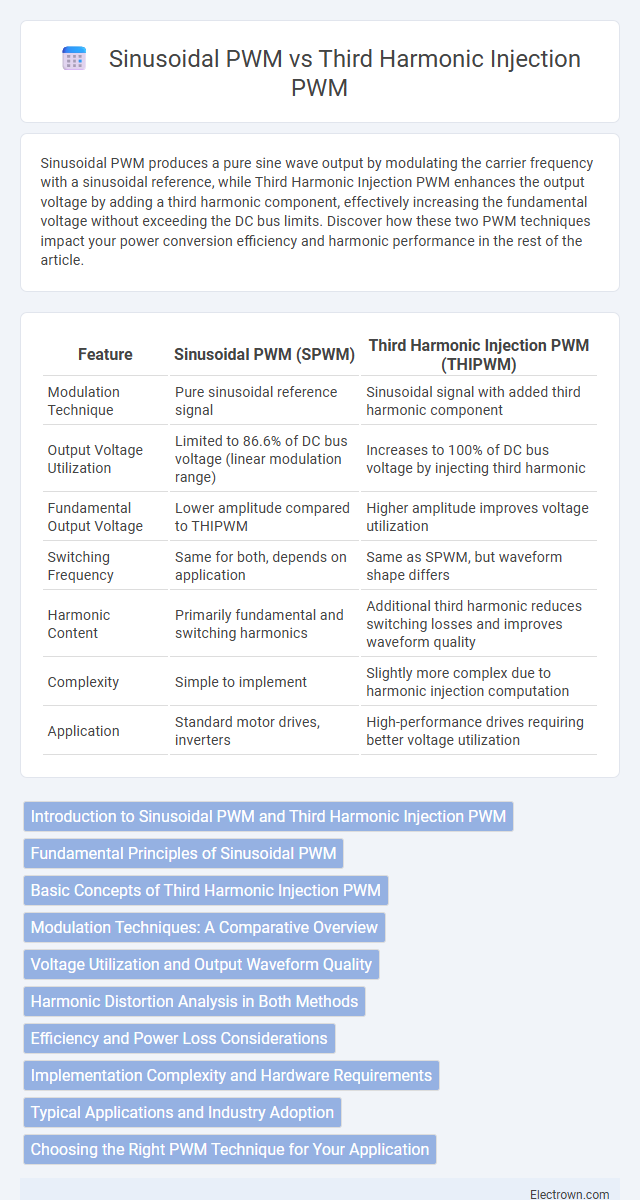

| Feature | Sinusoidal PWM (SPWM) | Third Harmonic Injection PWM (THIPWM) |

|---|---|---|

| Modulation Technique | Pure sinusoidal reference signal | Sinusoidal signal with added third harmonic component |

| Output Voltage Utilization | Limited to 86.6% of DC bus voltage (linear modulation range) | Increases to 100% of DC bus voltage by injecting third harmonic |

| Fundamental Output Voltage | Lower amplitude compared to THIPWM | Higher amplitude improves voltage utilization |

| Switching Frequency | Same for both, depends on application | Same as SPWM, but waveform shape differs |

| Harmonic Content | Primarily fundamental and switching harmonics | Additional third harmonic reduces switching losses and improves waveform quality |

| Complexity | Simple to implement | Slightly more complex due to harmonic injection computation |

| Application | Standard motor drives, inverters | High-performance drives requiring better voltage utilization |

Introduction to Sinusoidal PWM and Third Harmonic Injection PWM

Sinusoidal PWM (Pulse Width Modulation) controls inverter output voltage by comparing a sinusoidal reference signal with a high-frequency carrier to generate switching pulses, ensuring smooth, harmonic-minimized output waveforms. Third Harmonic Injection PWM enhances this technique by injecting a third harmonic component into the reference signal, increasing the maximum output voltage and improving inverter efficiency. Your choice between these methods depends on the specific application requirements for voltage modulation and harmonic reduction.

Fundamental Principles of Sinusoidal PWM

Sinusoidal PWM (Pulse Width Modulation) controls inverter output by comparing a sinusoidal reference signal with a high-frequency triangular carrier wave, generating pulses that vary in width to approximate the desired AC waveform. This fundamental principle ensures harmonic distortion is minimized and the output closely follows the sinusoidal reference, optimizing motor performance and reducing losses. Your inverter's efficiency and electrical waveform quality depend heavily on the precise modulation index and switching frequency used in Sinusoidal PWM.

Basic Concepts of Third Harmonic Injection PWM

Third Harmonic Injection PWM enhances traditional Sinusoidal PWM by superimposing a third harmonic component onto the reference waveform, enabling a higher modulation index and increased output voltage utilization. This technique minimizes the amplitude limitations of standard sinusoidal signals by flattening the waveform peaks, which allows for better DC bus voltage utilization without distortion. The third harmonic injection improves inverter efficiency and reduces harmonic distortion, resulting in smoother motor operation and reduced acoustic noise.

Modulation Techniques: A Comparative Overview

Sinusoidal PWM employs a pure sine wave reference to generate switching signals, resulting in lower harmonic distortion and simpler implementation in inverters. Third Harmonic Injection PWM enhances modulation index by adding a third harmonic component to the reference signal, improving voltage utilization without increasing switching losses. Both techniques optimize inverter performance, with third harmonic injection offering better DC bus voltage utilization and sinusoidal PWM providing cleaner output waveforms.

Voltage Utilization and Output Waveform Quality

Sinusoidal PWM typically achieves about 78.5% of the DC bus voltage utilization, while Third Harmonic Injection PWM enhances voltage utilization up to approximately 86.6% by injecting a third harmonic component to extend the fundamental voltage peak. This increased voltage utilization in Third Harmonic Injection PWM reduces voltage distortion, resulting in a higher quality output waveform with lower total harmonic distortion (THD) compared to standard Sinusoidal PWM. Consequently, Third Harmonic Injection PWM provides improved inverter performance with better waveform fidelity and higher voltage amplitude.

Harmonic Distortion Analysis in Both Methods

Sinusoidal PWM typically produces a fundamental frequency output with lower switching frequency harmonics but higher amplitude of lower-order harmonics, resulting in moderate Total Harmonic Distortion (THD). Third Harmonic Injection PWM reduces the amplitude of lower-order harmonics by injecting a third harmonic waveform into the modulation signal, effectively increasing the output voltage amplitude within the same DC bus voltage while lowering THD levels. Harmonic distortion analysis reveals that Third Harmonic Injection PWM achieves better harmonic performance by minimizing lower-order harmonics, enhancing motor efficiency, and reducing acoustic noise in power electronic drives.

Efficiency and Power Loss Considerations

Sinusoidal PWM typically offers straightforward implementation and moderate efficiency, but it can result in higher switching losses due to narrower pulse widths near zero crossing points. Third Harmonic Injection PWM enhances efficiency by increasing the fundamental output voltage and reducing the total harmonic distortion, leading to improved utilization of the DC bus voltage. This method reduces power losses by enabling higher amplitude modulation, which decreases both conduction and switching losses in power electronic devices.

Implementation Complexity and Hardware Requirements

Sinusoidal PWM (SPWM) features simpler implementation with basic sine wave reference generation and straightforward hardware, making it suitable for standard inverters with minimal processing capability. Third Harmonic Injection PWM (THIPWM) involves added complexity through the calculation and injection of a scaled third harmonic component, requiring more advanced digital signal processors and increased computational resources. While THIPWM enhances voltage utilization and reduces harmonic distortion, it demands higher hardware capabilities and more sophisticated control algorithms compared to SPWM.

Typical Applications and Industry Adoption

Sinusoidal PWM is widely adopted in industrial motor drives and inverter applications due to its ability to generate a clean sinusoidal output voltage, minimizing harmonic distortion and improving motor efficiency. Third Harmonic Injection PWM enhances the voltage output capability by injecting a third harmonic component, making it popular in high-performance variable-frequency drives and renewable energy inverters, where maximizing voltage utilization is crucial. Your choice between these methods depends on specific performance requirements, with Sinusoidal PWM favored for standard applications and Third Harmonic Injection PWM preferred in advanced systems demanding higher voltage output and efficiency.

Choosing the Right PWM Technique for Your Application

Sinusoidal PWM provides smooth and low-distortion output ideal for general motor control and inverter applications demanding high power quality. Third Harmonic Injection PWM enhances voltage utilization and increases the fundamental output voltage without increasing DC bus voltage, making it suitable for industrial drives needing higher voltage capacity. Your choice between these PWM techniques should depend on the required voltage amplitude, harmonic distortion tolerance, and efficiency objectives specific to your application.

Sinusoidal PWM vs Third Harmonic Injection PWM Infographic

electrown.com

electrown.com