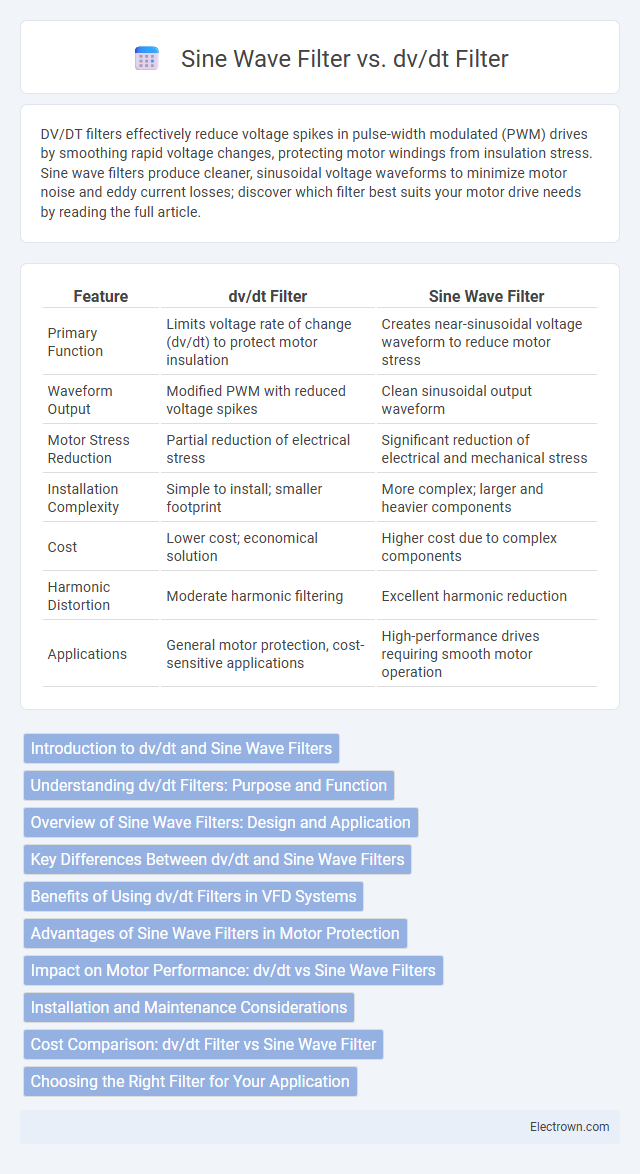

DV/DT filters effectively reduce voltage spikes in pulse-width modulated (PWM) drives by smoothing rapid voltage changes, protecting motor windings from insulation stress. Sine wave filters produce cleaner, sinusoidal voltage waveforms to minimize motor noise and eddy current losses; discover which filter best suits your motor drive needs by reading the full article.

Table of Comparison

| Feature | dv/dt Filter | Sine Wave Filter |

|---|---|---|

| Primary Function | Limits voltage rate of change (dv/dt) to protect motor insulation | Creates near-sinusoidal voltage waveform to reduce motor stress |

| Waveform Output | Modified PWM with reduced voltage spikes | Clean sinusoidal output waveform |

| Motor Stress Reduction | Partial reduction of electrical stress | Significant reduction of electrical and mechanical stress |

| Installation Complexity | Simple to install; smaller footprint | More complex; larger and heavier components |

| Cost | Lower cost; economical solution | Higher cost due to complex components |

| Harmonic Distortion | Moderate harmonic filtering | Excellent harmonic reduction |

| Applications | General motor protection, cost-sensitive applications | High-performance drives requiring smooth motor operation |

Introduction to dv/dt and Sine Wave Filters

Dv/dt filters reduce high-frequency voltage spikes caused by rapid switching in variable frequency drives, protecting motor insulation and extending equipment life. Sine wave filters smooth output voltage to create a near-pure sine wave, minimizing motor heating and noise, especially in long cable runs. Your system benefits from selecting the appropriate filter type based on switching frequency and motor sensitivity.

Understanding dv/dt Filters: Purpose and Function

Dv/dt filters reduce voltage spikes caused by rapid changes in voltage, protecting sensitive equipment and enhancing the lifespan of electrical components. Unlike sine wave filters that smooth out waveform distortions to improve power quality, dv/dt filters specifically target high-frequency voltage transitions to prevent insulation stress and electromagnetic interference. Understanding your system's voltage characteristics helps determine whether a dv/dt filter or sine wave filter best meets your performance and protection needs.

Overview of Sine Wave Filters: Design and Application

Sine wave filters are specialized devices designed to smooth out the output of variable frequency drives (VFDs), producing near-sinusoidal voltage waveforms that reduce motor insulation stress and minimize electromagnetic interference. These filters typically incorporate inductors, capacitors, and resistors to attenuate high-frequency harmonics and voltage spikes, enhancing the longevity and performance of sensitive motors in industrial applications. Your choice of a sine wave filter can improve system reliability by ensuring cleaner power delivery compared to conventional dv/dt filters, especially in long cable runs or applications requiring reduced bearing currents.

Key Differences Between dv/dt and Sine Wave Filters

dv/dt filters reduce voltage rate of change by smoothing high-frequency voltage spikes, protecting sensitive motor windings from electrical stress and insulation damage. Sine wave filters create a near-pure sine wave output by eliminating PWM carrier frequencies, minimizing motor noise, heat, and torque ripple for enhanced efficiency and longer motor life. Your choice depends on specific needs: dv/dt filters excel in motor insulation protection, while sine wave filters offer superior waveform quality and overall motor performance.

Benefits of Using dv/dt Filters in VFD Systems

Dv/dt filters reduce voltage spikes and electromagnetic interference in variable frequency drive (VFD) systems, extending the lifespan of motors and cable insulation. They effectively mitigate the high dv/dt rates caused by PWM output, preventing premature equipment failure and minimizing maintenance costs. By enhancing waveform quality and reducing harmonic distortion, dv/dt filters improve overall system reliability and energy efficiency.

Advantages of Sine Wave Filters in Motor Protection

Sine wave filters reduce the voltage dv/dt stress on motor windings, minimizing insulation wear and extending motor lifespan. Unlike dv/dt filters, sine wave filters deliver a cleaner, smoother waveform that limits high-frequency noise and electromagnetic interference, improving overall motor performance. Your motor's thermal and mechanical stress is significantly lowered with sine wave filters, enhancing reliability and reducing maintenance costs.

Impact on Motor Performance: dv/dt vs Sine Wave Filters

dv/dt filters reduce high-frequency voltage spikes caused by rapid switching in variable frequency drives (VFDs), protecting motor insulation and minimizing premature motor failure. Sine wave filters generate a smooth, low-distortion sinusoidal output that closely mimics utility power, leading to reduced motor heating, vibration, and audible noise. Understanding these impacts helps you select the right filter for improved motor longevity and optimal performance in your drive system.

Installation and Maintenance Considerations

DV/dt filters require precise installation near the inverter output to effectively reduce voltage rise time and protect motor windings, often involving compact components for space-saving integration. Sine wave filters, larger and heavier, demand more space and careful alignment for optimal performance, with increased complexity in wiring and grounding to ensure proper harmonic attenuation. Maintenance for dv/dt filters is generally simpler due to fewer components, whereas sine wave filters necessitate regular inspection to manage potential thermal and mechanical stresses over time.

Cost Comparison: dv/dt Filter vs Sine Wave Filter

Dv/dt filters generally offer a more cost-effective solution compared to sine wave filters due to their simpler design and lower material requirements. While sine wave filters provide superior harmonic reduction and smoother waveforms, their complexity leads to higher initial investment and maintenance costs. Your choice depends on balancing budget constraints with the desired level of power quality and motor protection.

Choosing the Right Filter for Your Application

Selecting the appropriate filter depends on your specific application's requirements for voltage spike suppression and signal integrity. A dv/dt filter excels in reducing high dv/dt values caused by fast-switching devices, protecting sensitive components and improving inverter performance. Sine wave filters are better suited for generating smoother output waveforms and minimizing motor noise and losses in variable frequency drive systems.

dv/dt filter vs sine wave filter Infographic

electrown.com

electrown.com