PWM frequency refers to how often the pulse width modulation signal repeats per second, directly affecting the resolution and smoothness of control in applications like motor drives and LED dimming. Switching frequency, on the other hand, is the rate at which the power device toggles on and off, influencing efficiency and heat dissipation; understanding these differences can optimize Your system's performance--read on to explore their distinct impacts in detail.

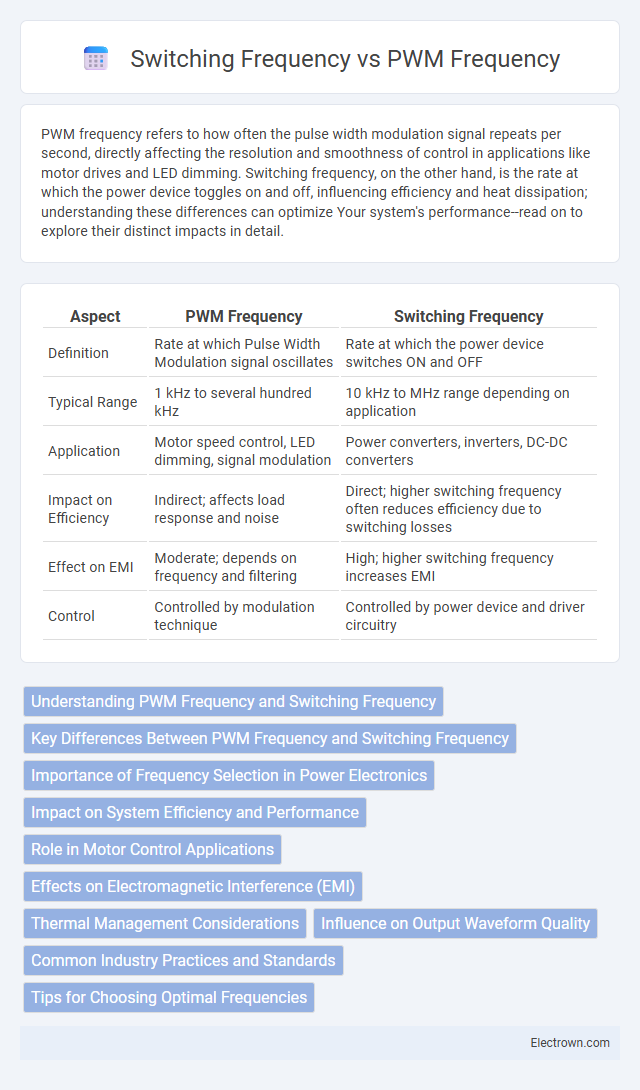

Table of Comparison

| Aspect | PWM Frequency | Switching Frequency |

|---|---|---|

| Definition | Rate at which Pulse Width Modulation signal oscillates | Rate at which the power device switches ON and OFF |

| Typical Range | 1 kHz to several hundred kHz | 10 kHz to MHz range depending on application |

| Application | Motor speed control, LED dimming, signal modulation | Power converters, inverters, DC-DC converters |

| Impact on Efficiency | Indirect; affects load response and noise | Direct; higher switching frequency often reduces efficiency due to switching losses |

| Effect on EMI | Moderate; depends on frequency and filtering | High; higher switching frequency increases EMI |

| Control | Controlled by modulation technique | Controlled by power device and driver circuitry |

Understanding PWM Frequency and Switching Frequency

PWM frequency determines how often the pulse width modulation signal cycles per second, directly influencing the resolution and smoothness of motor control or power delivery. Switching frequency refers to the rate at which a power semiconductor device, like a transistor, turns on and off in a power converter or inverter, impacting efficiency and electromagnetic interference levels. Optimizing your system requires balancing PWM frequency and switching frequency to achieve precise control while minimizing losses and noise.

Key Differences Between PWM Frequency and Switching Frequency

PWM frequency refers to the rate at which the pulse width modulation signal cycles per second, directly controlling the power delivered to a load by adjusting the duty cycle. Switching frequency specifically denotes the rate at which a power electronic device, such as a transistor or MOSFET, turns on and off within a power converter or inverter. The key difference lies in PWM frequency being a broader control parameter for modulation signals, while switching frequency is tied to the physical switching actions of power devices, impacting efficiency, electromagnetic interference, and thermal performance.

Importance of Frequency Selection in Power Electronics

Frequency selection in power electronics critically influences system efficiency and electromagnetic interference (EMI) levels. Pulse Width Modulation (PWM) frequency determines the granularity of control over power delivery, with higher frequencies enabling smoother output waveforms but increasing switching losses. Switching frequency impacts thermal management requirements and component stress, making optimal frequency choice essential for balancing performance, reliability, and energy efficiency in converters and inverters.

Impact on System Efficiency and Performance

PWM frequency directly influences switching frequency, affecting system efficiency and performance by controlling switching losses and electromagnetic interference (EMI). Higher switching frequencies reduce the size of passive components and improve transient response but increase switching losses, potentially lowering overall efficiency. Balancing PWM frequency with optimal switching frequency ensures minimized power dissipation while maintaining system stability and response speed.

Role in Motor Control Applications

PWM frequency determines the resolution of voltage control in motor applications, directly affecting torque smoothness and efficiency. Switching frequency influences the thermal performance and electromagnetic interference in motor drivers, impacting system reliability. Choosing the right balance between PWM frequency and switching frequency optimizes motor response, minimizing noise and extending the lifespan of your motor.

Effects on Electromagnetic Interference (EMI)

PWM frequency directly influences the switching frequency, which significantly affects Electromagnetic Interference (EMI) levels in electronic circuits. Higher switching frequencies can generate more EMI due to rapid voltage and current changes, requiring careful filtering and shielding design to protect sensitive components. Optimizing your PWM frequency helps balance efficient performance while minimizing EMI emissions for improved device reliability and compliance.

Thermal Management Considerations

PWM frequency and switching frequency directly impact thermal management by influencing power dissipation in electronic components. Higher switching frequencies typically increase switching losses, leading to greater heat generation that requires enhanced cooling solutions such as heat sinks or active fans. Optimizing your device's switching frequency helps balance performance and thermal efficiency, preventing overheating and ensuring reliable operation.

Influence on Output Waveform Quality

PWM frequency directly impacts the smoothness and resolution of the output waveform, with higher frequencies allowing finer control and reduced harmonic distortion. Switching frequency determines the rate at which the power devices toggle, influencing electromagnetic interference and efficiency but possibly introducing higher switching losses. Optimal selection balances these frequencies to achieve high-quality output waveforms with minimal distortion and noise.

Common Industry Practices and Standards

PWM frequency and switching frequency are critical parameters in power electronics, commonly set between 20 kHz and 100 kHz in industry to balance efficiency, electromagnetic interference, and thermal management. Standard practices often specify switching frequencies at 50 kHz for general-purpose converters, while high-performance systems may operate up to 200 kHz to reduce passive component size. Your device's optimal frequency should align with industry standards such as IEC 61000 for electromagnetic compatibility to ensure reliable and compliant operation.

Tips for Choosing Optimal Frequencies

Selecting the optimal PWM frequency involves balancing efficiency, noise, and thermal performance; lower frequencies reduce switching losses but can cause audible noise, while higher frequencies improve output smoothness yet increase heat generation. Consider your application's requirements, such as the type of load and sensitivity to electromagnetic interference, when determining the switching frequency to ensure stability and efficiency. Your choice of frequency should also account for the capabilities of your power components to avoid excessive stress and maintain long-term reliability.

pwm frequency vs switching frequency Infographic

electrown.com

electrown.com