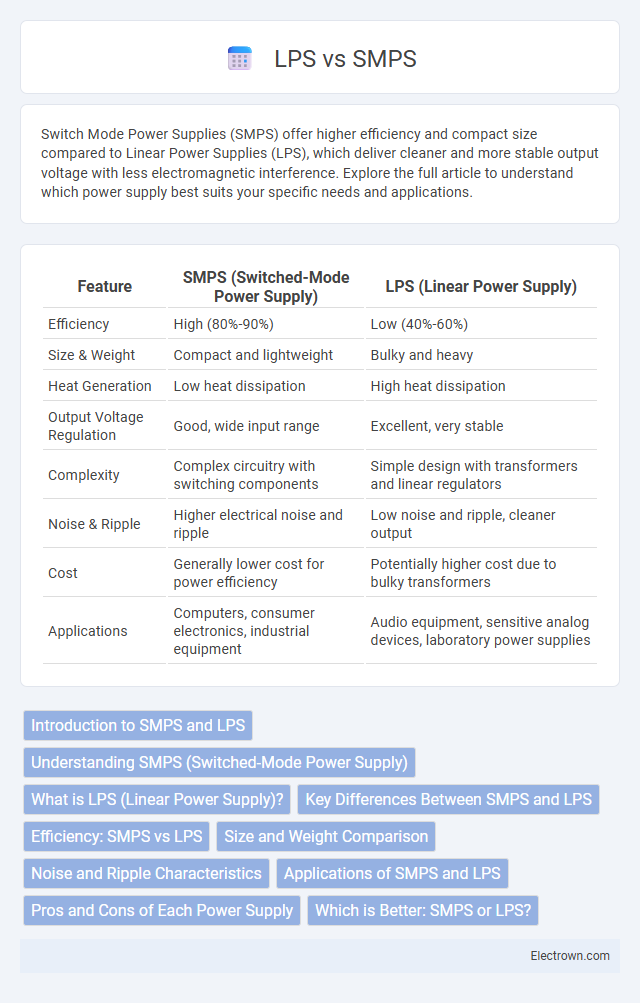

Switch Mode Power Supplies (SMPS) offer higher efficiency and compact size compared to Linear Power Supplies (LPS), which deliver cleaner and more stable output voltage with less electromagnetic interference. Explore the full article to understand which power supply best suits your specific needs and applications.

Table of Comparison

| Feature | SMPS (Switched-Mode Power Supply) | LPS (Linear Power Supply) |

|---|---|---|

| Efficiency | High (80%-90%) | Low (40%-60%) |

| Size & Weight | Compact and lightweight | Bulky and heavy |

| Heat Generation | Low heat dissipation | High heat dissipation |

| Output Voltage Regulation | Good, wide input range | Excellent, very stable |

| Complexity | Complex circuitry with switching components | Simple design with transformers and linear regulators |

| Noise & Ripple | Higher electrical noise and ripple | Low noise and ripple, cleaner output |

| Cost | Generally lower cost for power efficiency | Potentially higher cost due to bulky transformers |

| Applications | Computers, consumer electronics, industrial equipment | Audio equipment, sensitive analog devices, laboratory power supplies |

Introduction to SMPS and LPS

Switched-Mode Power Supplies (SMPS) and Linear Power Supplies (LPS) are two primary types of electronic power converters used to provide regulated output voltage. SMPS operates by rapidly switching transistors on and off, converting electrical power efficiently with minimal heat generation, making it suitable for compact and high-power applications. LPS delivers power through a linear regulator, offering low noise and stable outputs ideal for sensitive analog and audio devices but often results in larger size and lower efficiency due to heat dissipation.

Understanding SMPS (Switched-Mode Power Supply)

SMPS (Switched-Mode Power Supply) efficiently converts electrical power through high-frequency switching regulators, enabling compact design and improved energy efficiency compared to traditional linear power supplies (LPS). By rapidly switching transistors on and off, SMPS regulates output voltage with minimal heat generation and high power density. Key applications include computers, telecommunications, and industrial equipment where lightweight and reliable power conversion is critical.

What is LPS (Linear Power Supply)?

Linear Power Supply (LPS) converts AC voltage to a stable DC output using a transformer, rectifier, and filter capacitor, ensuring low ripple and noise. Unlike Switching Mode Power Supplies (SMPS), LPS operates by dissipating excess voltage as heat, offering superior electromagnetic interference (EMI) performance. You benefit from LPS in applications requiring clean and stable power, such as audio equipment and sensitive analog circuits.

Key Differences Between SMPS and LPS

SMPS (Switch Mode Power Supply) operates by rapidly switching electronic components on and off to regulate voltage efficiently, whereas LPS (Linear Power Supply) uses a transformer and linear regulator for voltage conversion, resulting in less efficiency but lower noise output. SMPS is compact, lightweight, and suitable for high-power applications due to its high efficiency, while LPS tends to be bulkier with higher heat dissipation but provides cleaner, ripple-free power ideal for sensitive audio and communication equipment. Key differences include efficiency, size, noise levels, and electromagnetic interference, making the choice dependent on application requirements.

Efficiency: SMPS vs LPS

Switched-Mode Power Supplies (SMPS) typically achieve efficiency rates between 80% and 90%, significantly higher than Linear Power Supplies (LPS), which generally operate around 50% to 60% efficiency. SMPS use high-frequency switching regulators to minimize energy loss during voltage conversion, reducing heat dissipation and improving overall power handling. In contrast, LPS rely on dissipative linear regulation techniques that inherently waste more energy as heat, making SMPS the preferred choice for energy-conscious and compact electronic applications.

Size and Weight Comparison

SMPS (Switched-Mode Power Supply) units are generally smaller and lighter than LPS (Linear Power Supply) because they use high-frequency switching components, allowing compact transformers and efficient heat dissipation. LPS relies on bulky iron-core transformers and large heat sinks, resulting in increased size and weight. Your choice between SMPS and LPS depends on space constraints and portability requirements, with SMPS typically preferred for compact and lightweight applications.

Noise and Ripple Characteristics

Switching Mode Power Supplies (SMPS) typically exhibit higher noise and ripple levels due to high-frequency switching components, which can affect sensitive electronic circuits. Linear Power Supplies (LPS) provide cleaner output with minimal noise and ripple, making them ideal for audio and precision instrumentation applications. Choosing your power supply depends on balancing efficiency requirements against noise tolerance in your specific device.

Applications of SMPS and LPS

SMPS (Switched-Mode Power Supply) is widely used in applications requiring high efficiency and compact size, such as computers, telecommunications equipment, and consumer electronics. LPS (Linear Power Supply) is preferred in audio equipment, medical devices, and sensitive instrumentation due to its low noise and stable output voltage. Your choice between SMPS and LPS depends largely on the specific power quality and efficiency requirements of your application.

Pros and Cons of Each Power Supply

Switch Mode Power Supply (SMPS) offers high efficiency, compact size, and lightweight design, making it ideal for modern electronic devices, but it may generate electromagnetic interference and has a complex circuit design. Linear Power Supply (LPS) provides low noise and stable output with simple construction, which is advantageous for sensitive applications, but it is bulky, heavy, and less energy-efficient due to heat dissipation. Choosing between SMPS and LPS depends on specific requirements such as efficiency, size constraints, noise tolerance, and cost considerations.

Which is Better: SMPS or LPS?

SMPS (Switched-Mode Power Supplies) offer higher efficiency, compact size, and better thermal performance compared to LPS (Linear Power Supplies), making them ideal for modern electronic devices. LPS provide cleaner, low-ripple output voltage with minimal electromagnetic interference, essential for sensitive audio and RF applications. Choosing between SMPS and LPS depends on specific requirements: SMPS excel in energy-saving and space-limited scenarios, while LPS are preferred for noise-sensitive environments.

smps vs lps Infographic

electrown.com

electrown.com