Digital isolators offer faster signal transmission, lower power consumption, and longer lifespan compared to traditional optocouplers, which rely on LED-phototransistor pairs and suffer from slower response times and degradation over time. Explore the rest of the article to understand which technology best suits Your application needs.

Table of Comparison

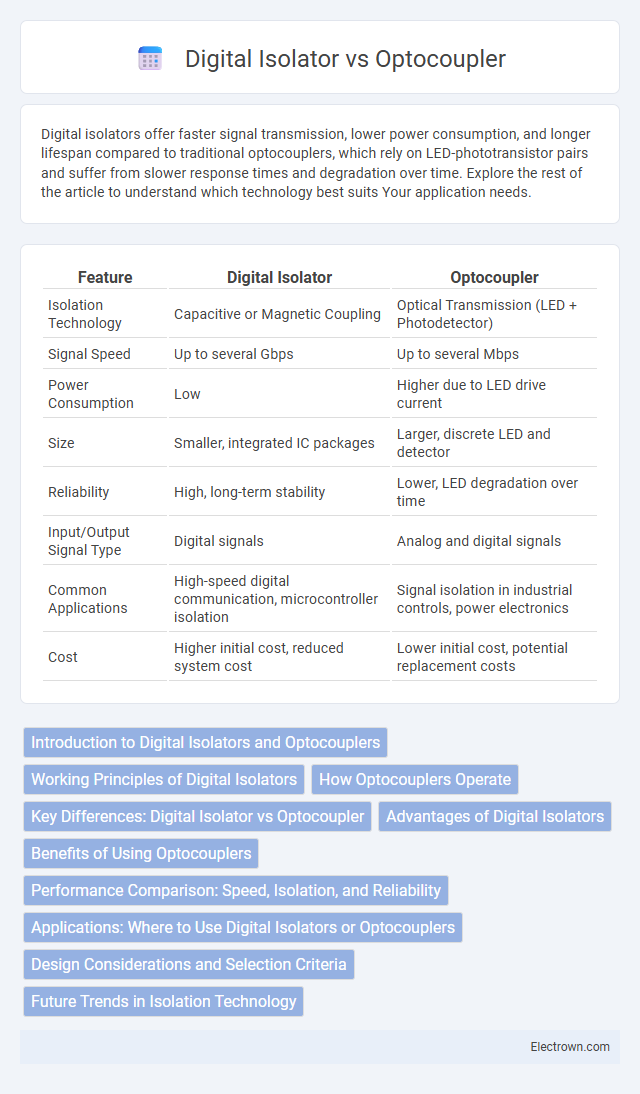

| Feature | Digital Isolator | Optocoupler |

|---|---|---|

| Isolation Technology | Capacitive or Magnetic Coupling | Optical Transmission (LED + Photodetector) |

| Signal Speed | Up to several Gbps | Up to several Mbps |

| Power Consumption | Low | Higher due to LED drive current |

| Size | Smaller, integrated IC packages | Larger, discrete LED and detector |

| Reliability | High, long-term stability | Lower, LED degradation over time |

| Input/Output Signal Type | Digital signals | Analog and digital signals |

| Common Applications | High-speed digital communication, microcontroller isolation | Signal isolation in industrial controls, power electronics |

| Cost | Higher initial cost, reduced system cost | Lower initial cost, potential replacement costs |

Introduction to Digital Isolators and Optocouplers

Digital isolators employ capacitive or magnetic coupling to transfer signals while providing high-speed data transmission and enhanced reliability. Optocouplers use LED and photodetector components to achieve electrical isolation, offering robust noise immunity but with limited bandwidth. Your choice depends on application requirements involving speed, isolation voltage, and signal integrity needs.

Working Principles of Digital Isolators

Digital isolators utilize capacitive or magnetic coupling techniques to transmit digital signals across an isolation barrier without direct electrical connection, ensuring robust signal integrity and high-speed data transfer. These devices convert the input signal into a high-frequency carrier, which is then detected and decoded on the output side, providing galvanic isolation while maintaining low power consumption and minimal propagation delay. In contrast, optocouplers rely on light emission and photodetection, which typically results in slower response times and larger size.

How Optocouplers Operate

Optocouplers operate by transferring electrical signals using light, where an LED inside the device emits infrared light when an input voltage is applied, and a photodetector on the output side detects this light to recreate the signal while maintaining electrical isolation. This optical method provides galvanic isolation, preventing high voltages from damaging sensitive components or interfering with signal integrity. Understanding how optocouplers work can help you choose the right isolation method for protecting circuits and ensuring reliable signal transmission.

Key Differences: Digital Isolator vs Optocoupler

Digital isolators use capacitive or magnetic coupling to transfer signals with high speed and low power consumption, while optocouplers rely on an LED and photodetector to provide electrical isolation but suffer from slower response times and limited lifespan. Digital isolators offer superior signal integrity, higher data rates up to several Mbps or Gbps, and better noise immunity compared to optocouplers, which are more susceptible to degradation over time. Your choice depends on requirements for speed, longevity, and efficiency in isolating sensitive electronics in industrial or medical applications.

Advantages of Digital Isolators

Digital isolators offer faster data transmission speeds, reaching up to several Mbps compared to optocouplers, which typically operate at lower bandwidths. They provide higher reliability and longer lifespan due to solid-state construction without LEDs or photodetectors that degrade over time. Digital isolators also deliver lower power consumption and improved noise immunity, making them ideal for precise and efficient signal isolation in modern electronic systems.

Benefits of Using Optocouplers

Optocouplers provide galvanic isolation by using light to transfer signals, ensuring effective noise immunity and protection in high-voltage environments. They offer a wide input-output voltage isolation range, typically up to 5 kV or more, making them ideal for industrial and medical applications. Optocouplers also exhibit excellent transient immunity and compatibility with both AC and DC signals, enhancing system reliability in harsh operating conditions.

Performance Comparison: Speed, Isolation, and Reliability

Digital isolators offer significantly faster data transfer rates, typically up to several hundred Mbps, compared to optocouplers, which usually max out at a few Mbps. Both technologies provide electrical isolation, but digital isolators achieve higher isolation voltage levels (up to 5 kV or more) with better signal integrity and lower propagation delay. Digital isolators also exhibit greater reliability due to solid-state construction, longer lifespan, and resistance to LED degradation that commonly affects optocouplers.

Applications: Where to Use Digital Isolators or Optocouplers

Digital isolators excel in high-speed data communication, precision sensor interfaces, and power supply isolation due to their fast switching speeds and low power consumption. Optocouplers are ideal for electrical noise reduction in industrial control systems, motor drives, and legacy equipment needing galvanic isolation with robust voltage tolerance. Your choice depends on whether high-speed digital signal integrity or reliable isolation in harsh environments is the priority.

Design Considerations and Selection Criteria

Digital isolators offer higher data rates, lower power consumption, and enhanced signal integrity compared to optocouplers, making them ideal for modern high-speed communication systems. Optocouplers provide galvanic isolation with proven noise immunity but have slower switching speeds and limited lifetime due to LED degradation. Design considerations involve evaluating isolation voltage requirements, signal bandwidth, power efficiency, and environmental conditions to select the appropriate device for robust and reliable isolation.

Future Trends in Isolation Technology

Digital isolators are advancing with higher data rates, lower power consumption, and smaller form factors, making them ideal for next-generation communication systems and industrial automation. Optocouplers remain relevant for high-voltage isolation but are gradually being replaced by semiconductor-based digital isolators that offer improved reliability and integration. Emerging trends emphasize enhanced integration with system-on-chip (SoC) designs, support for higher temperature ranges, and compatibility with advanced safety standards in electric vehicles and smart grids.

Digital isolator vs Optocoupler Infographic

electrown.com

electrown.com