EMI filters are designed to suppress electromagnetic interference that affects device performance, while RFI filters specifically target radio frequency interference to prevent signal disruption. Understanding the differences between these filters can help you choose the right solution for improving your electronic system's reliability--read on to explore their distinct applications and benefits.

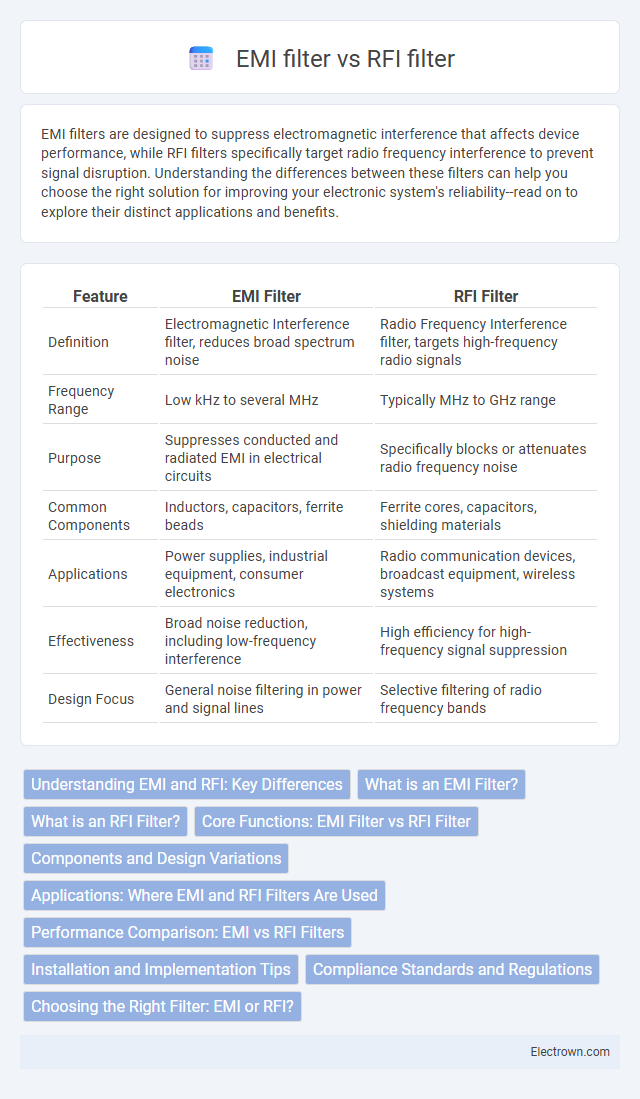

Table of Comparison

| Feature | EMI Filter | RFI Filter |

|---|---|---|

| Definition | Electromagnetic Interference filter, reduces broad spectrum noise | Radio Frequency Interference filter, targets high-frequency radio signals |

| Frequency Range | Low kHz to several MHz | Typically MHz to GHz range |

| Purpose | Suppresses conducted and radiated EMI in electrical circuits | Specifically blocks or attenuates radio frequency noise |

| Common Components | Inductors, capacitors, ferrite beads | Ferrite cores, capacitors, shielding materials |

| Applications | Power supplies, industrial equipment, consumer electronics | Radio communication devices, broadcast equipment, wireless systems |

| Effectiveness | Broad noise reduction, including low-frequency interference | High efficiency for high-frequency signal suppression |

| Design Focus | General noise filtering in power and signal lines | Selective filtering of radio frequency bands |

Understanding EMI and RFI: Key Differences

EMI filters primarily target electromagnetic interference caused by both conducted and radiated noise across a broad frequency range, while RFI filters specifically address high-frequency radio frequency interference often stemming from wireless transmissions and electronic devices. Understanding these distinctions helps ensure your electronic systems effectively reduce unwanted signals, improving performance and compliance with regulatory standards. Selecting the appropriate filter type depends on the interference source and frequency characteristics present in your application.

What is an EMI Filter?

An EMI filter is a specialized electronic component designed to suppress electromagnetic interference (EMI) in electrical circuits, ensuring the proper functioning of sensitive devices by blocking unwanted high-frequency noise signals. It typically consists of inductors and capacitors arranged to attenuate conducted noise without affecting the desired signal flow. EMI filters are crucial in various applications, including power supplies, medical equipment, and telecommunications, to maintain electromagnetic compatibility (EMC) and meet regulatory standards.

What is an RFI Filter?

An RFI filter is a specialized electronic component designed to suppress radio frequency interference (RFI) that can disrupt the performance of electronic devices and communication systems. Unlike EMI filters that target a broader range of electromagnetic disturbances, RFI filters specifically focus on high-frequency noise generated by radio waves. Your equipment's signal integrity and overall functionality can be significantly improved by integrating an RFI filter, ensuring clearer transmissions and reduced interference.

Core Functions: EMI Filter vs RFI Filter

EMI filters primarily suppress electromagnetic interference by attenuating unwanted high-frequency noise signals within a specified frequency range to protect sensitive electronic equipment. RFI filters focus on reducing radio frequency interference, targeting emissions in the radio frequency spectrum that can disrupt communication and broadcast signals. Both filters utilize inductors, capacitors, and resistors but differ in design specifications optimized for their respective interference frequencies.

Components and Design Variations

EMI filters and RFI filters both utilize inductors, capacitors, and resistors to suppress unwanted interference, but their design variations target different frequency ranges; EMI filters typically address a broader spectrum including both conducted and radiated noise, while RFI filters specialize in higher-frequency radio signals. Common EMI filter components include common-mode chokes and X/Y capacitors arranged to attenuate electromagnetic noise effectively, whereas RFI filters emphasize precision-tuned capacitors and inductors to block radio-frequency interference specifically. Your choice between the two depends on the interference source and the necessary attenuation frequency range within your electronic system.

Applications: Where EMI and RFI Filters Are Used

EMI filters are predominantly used in power supplies, medical equipment, and industrial machinery to reduce electromagnetic interference from switching devices and motors. RFI filters are commonly applied in radio communication devices, audio equipment, and broadcast transmitters to suppress high-frequency radio signals and prevent noise in RF circuits. Both filters play a critical role in ensuring compliance with regulatory standards such as FCC, CISPR, and MIL-STD in their respective applications.

Performance Comparison: EMI vs RFI Filters

EMI filters primarily target a broad range of electromagnetic interference frequencies to improve overall signal integrity, while RFI filters focus specifically on suppressing high-frequency radio frequency interference. EMI filters often include components like inductors and capacitors to attenuate both conducted and radiated noise, offering versatile performance for various applications. RFI filters, designed with specialized high-frequency attenuation elements, excel in environments with intense radio frequency noise, delivering superior suppression at higher frequencies but potentially less effectiveness against lower-frequency electromagnetic disturbances.

Installation and Implementation Tips

EMI filters require careful grounding and shielding during installation to minimize electromagnetic interference, ensuring optimal performance in sensitive electronic environments. RFI filters should be placed as close as possible to the noise source or equipment to effectively suppress high-frequency radio frequency interference; proper wiring and avoiding loop areas are critical for installation. Selecting the right filter type based on the frequency range and load conditions, along with following manufacturer guidelines, enhances implementation success for both EMI and RFI filters.

Compliance Standards and Regulations

EMI filters and RFI filters both play critical roles in meeting electromagnetic compatibility (EMC) compliance standards such as CISPR 22, FCC Part 15, and IEC 61000-4-3, ensuring devices pass interference and immunity testing. EMI filters typically address a broader spectrum of conducted and radiated emissions, aligning with stringent regulations for commercial and industrial equipment. RFI filters, focusing on high-frequency radio frequency interference suppression, are essential for compliance in environments requiring protection against specific radio bandwidths, such as telecommunications and broadcast equipment.

Choosing the Right Filter: EMI or RFI?

Choosing the right filter depends on the specific interference type; EMI filters target a broad range of electromagnetic disturbances across frequencies, while RFI filters specialize in suppressing high-frequency radio signals. EMI filters are ideal for environments with diverse electromagnetic noise from power lines and industrial equipment, offering wide-spectrum attenuation. RFI filters excel in applications involving radio frequency interference from wireless communication devices, ensuring improved signal integrity and compliance with regulatory standards.

EMI filter vs RFI filter Infographic

electrown.com

electrown.com