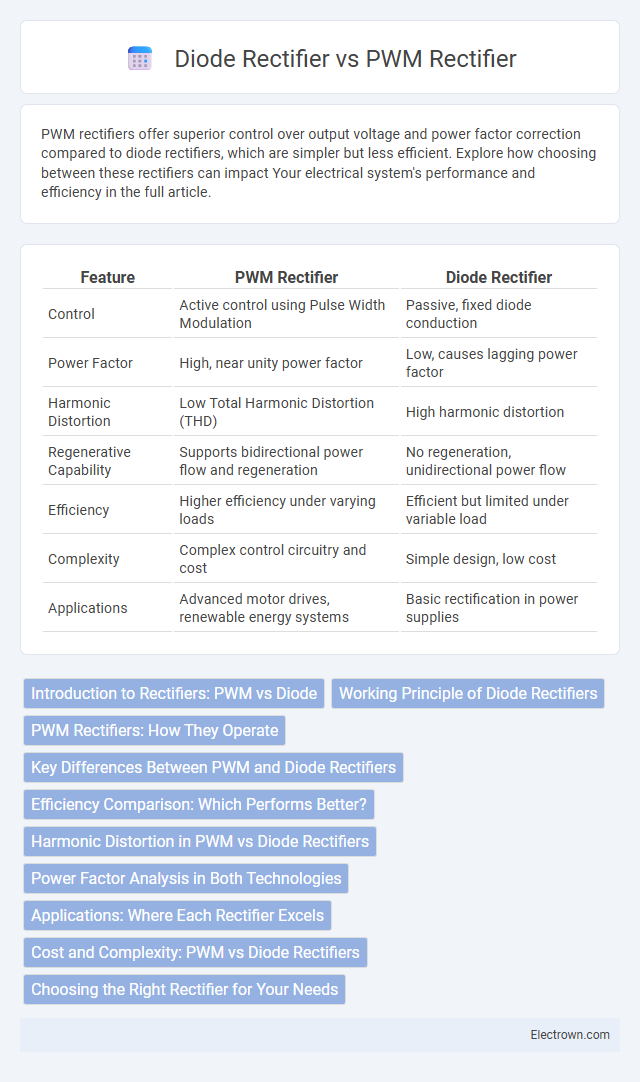

PWM rectifiers offer superior control over output voltage and power factor correction compared to diode rectifiers, which are simpler but less efficient. Explore how choosing between these rectifiers can impact Your electrical system's performance and efficiency in the full article.

Table of Comparison

| Feature | PWM Rectifier | Diode Rectifier |

|---|---|---|

| Control | Active control using Pulse Width Modulation | Passive, fixed diode conduction |

| Power Factor | High, near unity power factor | Low, causes lagging power factor |

| Harmonic Distortion | Low Total Harmonic Distortion (THD) | High harmonic distortion |

| Regenerative Capability | Supports bidirectional power flow and regeneration | No regeneration, unidirectional power flow |

| Efficiency | Higher efficiency under varying loads | Efficient but limited under variable load |

| Complexity | Complex control circuitry and cost | Simple design, low cost |

| Applications | Advanced motor drives, renewable energy systems | Basic rectification in power supplies |

Introduction to Rectifiers: PWM vs Diode

PWM rectifiers provide advanced control over electrical power by converting AC to DC with high efficiency and reduced harmonic distortion, unlike traditional diode rectifiers that rely on passive components and produce fixed DC output with higher ripple. Your choice between PWM and diode rectifiers impacts power quality, efficiency, and system responsiveness, especially in applications requiring precise voltage regulation and bidirectional power flow. PWM rectifiers use active switching elements and control algorithms to optimize performance, whereas diode rectifiers offer simplicity and lower cost but limited control capabilities.

Working Principle of Diode Rectifiers

Diode rectifiers operate by allowing current to flow in only one direction through semiconductor diodes, converting alternating current (AC) into direct current (DC). The diodes conduct during the positive half-cycles of the AC waveform, blocking reverse flow and producing a pulsating DC output. This basic unidirectional conduction results in lower complexity but limited control over output voltage and power factor compared to PWM rectifiers.

PWM Rectifiers: How They Operate

PWM rectifiers operate by converting AC to DC using controlled semiconductor switches like IGBTs, which modulate the input current waveform through pulse-width modulation to reduce harmonics and improve power factor. Unlike diode rectifiers, which rely on passive diodes and produce fixed, non-controllable output with limited power quality, PWM rectifiers actively shape the input current to achieve near-sinusoidal waveforms and bidirectional power flow. This precise control enables enhanced efficiency, regenerative braking capabilities, and compliance with stringent grid standards.

Key Differences Between PWM and Diode Rectifiers

PWM rectifiers offer controlled, bidirectional power flow with higher efficiency and reduced harmonic distortion compared to traditional diode rectifiers, which only allow unidirectional current flow and generate more harmonic noise. Your system benefits from PWM rectifiers' ability to regulate output voltage and power factor precisely, enhancing overall energy quality and reducing losses. Diode rectifiers, while simpler and cost-effective, lack the advanced control and performance features found in PWM rectifiers, making them less suitable for dynamic or sensitive applications.

Efficiency Comparison: Which Performs Better?

PWM rectifiers outperform diode rectifiers in efficiency by actively controlling the input current waveform and minimizing power losses, often achieving efficiency rates above 95%. Diode rectifiers, while simpler and cheaper, suffer from higher conduction losses and poor power factor, typically resulting in lower overall efficiency, especially under variable load conditions. For your applications demanding high energy efficiency and reduced harmonic distortion, PWM rectifiers offer superior performance and energy savings.

Harmonic Distortion in PWM vs Diode Rectifiers

PWM rectifiers significantly reduce harmonic distortion compared to diode rectifiers by actively controlling the input current waveform to closely follow a sinusoidal shape, resulting in lower total harmonic distortion (THD) levels often below 5%. Diode rectifiers generate highly distorted, non-sinusoidal currents with higher THD, typically above 30%, which can cause power quality issues and additional stress on electrical equipment. Your choice of a PWM rectifier improves power factor and meets harmonic distortion standards more effectively than traditional diode rectifiers.

Power Factor Analysis in Both Technologies

PWM rectifiers maintain a high power factor near unity by actively controlling the input current waveform, minimizing harmonic distortion and reactive power. Diode rectifiers inherently produce a lower power factor due to their non-controlled, nonlinear input current, resulting in significant harmonic distortion and reduced efficiency. Advanced PWM technology enables improved power quality and compliance with IEEE IEEE-519 standards compared to traditional diode rectifier setups.

Applications: Where Each Rectifier Excels

PWM rectifiers excel in applications requiring precise control and bi-directional power flow, such as renewable energy systems, electric vehicle chargers, and uninterruptible power supplies (UPS). Diode rectifiers are ideal for simple, cost-effective AC to DC conversion in low-complexity applications like basic power supplies and standard motor drives. The choice between PWM and diode rectifiers depends on the need for efficiency, power quality, and control complexity in the specific industrial or commercial application.

Cost and Complexity: PWM vs Diode Rectifiers

PWM rectifiers tend to have higher initial costs and increased complexity due to their use of active switching components and control circuits, whereas diode rectifiers are simpler and more cost-effective with passive components. The complexity of PWM rectifiers enables improved power quality and efficiency, justifying the investment in applications where precise control is critical. Understanding these trade-offs helps you choose the appropriate rectifier based on budget and performance requirements.

Choosing the Right Rectifier for Your Needs

PWM rectifiers offer superior power factor correction and reduced harmonics compared to diode rectifiers, making them ideal for applications demanding high efficiency and grid compliance. Diode rectifiers provide simplicity and lower initial cost but lack controllability and generate higher harmonic distortion. Selecting between PWM and diode rectifiers depends on factors such as power quality requirements, budget constraints, and the complexity of the electrical system.

pwm rectifier vs diode rectifier Infographic

electrown.com

electrown.com