CCM boost converters regulate output current by maintaining continuous inductor current flow, offering higher efficiency and lower ripple in high-power applications, whereas DCM boost converters operate with the inductor current falling to zero each cycle, simplifying control and reducing switching losses at light loads. Discover which boost converter best suits Your specific power management needs in the detailed comparison ahead.

Table of Comparison

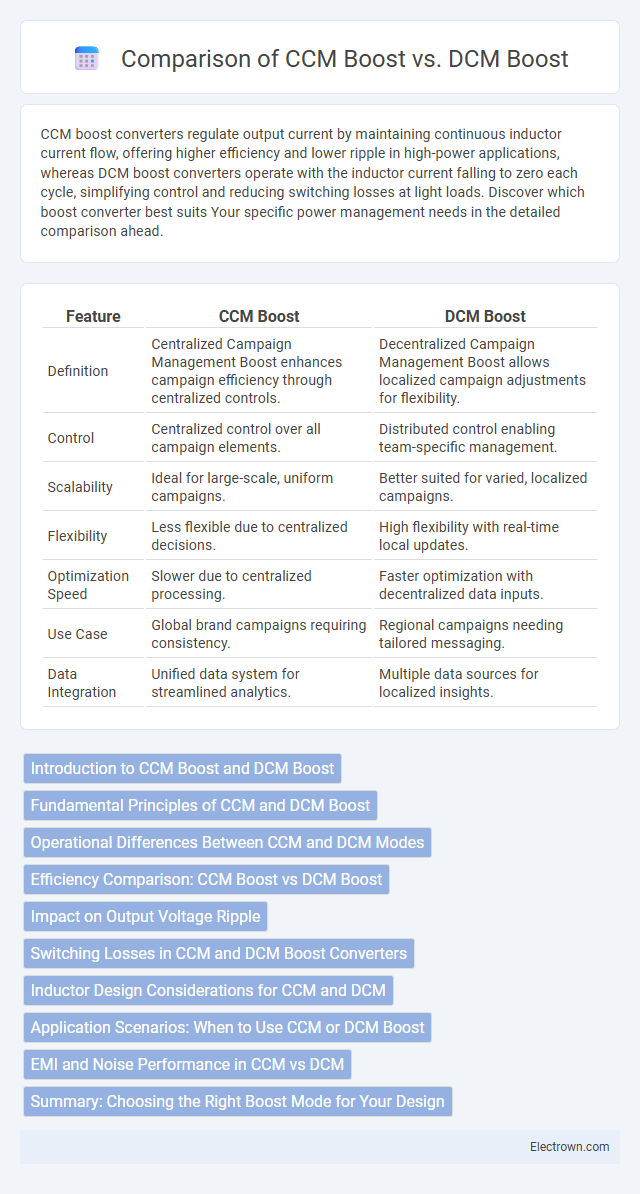

| Feature | CCM Boost | DCM Boost |

|---|---|---|

| Definition | Centralized Campaign Management Boost enhances campaign efficiency through centralized controls. | Decentralized Campaign Management Boost allows localized campaign adjustments for flexibility. |

| Control | Centralized control over all campaign elements. | Distributed control enabling team-specific management. |

| Scalability | Ideal for large-scale, uniform campaigns. | Better suited for varied, localized campaigns. |

| Flexibility | Less flexible due to centralized decisions. | High flexibility with real-time local updates. |

| Optimization Speed | Slower due to centralized processing. | Faster optimization with decentralized data inputs. |

| Use Case | Global brand campaigns requiring consistency. | Regional campaigns needing tailored messaging. |

| Data Integration | Unified data system for streamlined analytics. | Multiple data sources for localized insights. |

Introduction to CCM Boost and DCM Boost

CCM Boost and DCM Boost are advanced power factor correction techniques used in switching power supplies to optimize efficiency and reduce electromagnetic interference. CCM (Continuous Conduction Mode) Boost maintains a continuous inductor current, minimizing ripple and improving output voltage stability, while DCM (Discontinuous Conduction Mode) Boost allows the current to drop to zero each cycle, enhancing transient response and reducing switching losses. Understanding the differences between CCM and DCM Boost can help you select the appropriate topology for your power conversion design to balance efficiency, size, and cost.

Fundamental Principles of CCM and DCM Boost

CCM (Continuous Conduction Mode) boost converters maintain current flow through the inductor at all times, minimizing ripple and improving efficiency in high-power applications. In contrast, DCM (Discontinuous Conduction Mode) boost converters allow the inductor current to drop to zero each switching cycle, simplifying control and enabling lighter, more compact designs suitable for low-power scenarios. Understanding these fundamental principles helps you select the appropriate boost topology to optimize performance and efficiency in your power supply design.

Operational Differences Between CCM and DCM Modes

CCM (Continuous Conduction Mode) boost converters maintain inductor current at all times, resulting in lower current ripple and higher efficiency under steady loads. DCM (Discontinuous Conduction Mode) boost converters allow the inductor current to drop to zero during each switching cycle, which simplifies control but increases current ripple and electromagnetic interference. Understanding these operational differences helps optimize Your power supply design for specific load conditions and efficiency requirements.

Efficiency Comparison: CCM Boost vs DCM Boost

CCM (Continuous Conduction Mode) boost converters generally offer higher efficiency at medium to high load currents due to lower current ripple and reduced switching losses. DCM (Discontinuous Conduction Mode) boost converters can be more efficient at light loads because they minimize conduction losses by allowing the inductor current to fully discharge each cycle. Understanding the efficiency trade-offs between CCM and DCM boost modes helps optimize Your power supply design based on specific load conditions.

Impact on Output Voltage Ripple

CCM (Continuous Conduction Mode) boost converters generally exhibit lower output voltage ripple due to the inductor current flowing continuously, which smooths the energy transfer to the output. In contrast, DCM (Discontinuous Conduction Mode) boost converters experience higher output voltage ripple since the inductor current falls to zero during part of the switching cycle, causing more significant voltage fluctuations. The continuous energy flow in CCM reduces output voltage ripple, making it more suitable for applications demanding stable voltage output.

Switching Losses in CCM and DCM Boost Converters

Switching losses in Continuous Conduction Mode (CCM) boost converters typically increase due to prolonged overlap between voltage and current during the transistor's switching transitions. Discontinuous Conduction Mode (DCM) boost converters experience lower switching losses since the inductor current falls to zero before the next switching cycle, reducing the switching overlap duration. The trade-off involves DCM converters having higher peak currents, which can lead to increased conduction losses despite their lower switching losses compared to CCM.

Inductor Design Considerations for CCM and DCM

Inductor design for Continuous Conduction Mode (CCM) boost converters requires minimizing core losses and ensuring sufficient inductance to maintain continuous current, often leading to larger core sizes and low DCR to reduce conduction losses. Discontinuous Conduction Mode (DCM) boost inductors can be smaller and use higher inductance ripple due to the current dropping to zero each switching cycle, but they must handle higher peak currents, necessitating careful thermal management and saturated flux density considerations. Selecting the appropriate core material and inductance is critical for maximizing efficiency and reliability under the distinct current waveforms in CCM and DCM operation.

Application Scenarios: When to Use CCM or DCM Boost

CCM (Continuous Conduction Mode) boost converters are ideal for applications requiring high power efficiency and low output voltage ripple, such as battery charging and power supply circuits in industrial equipment. DCM (Discontinuous Conduction Mode) boost converters suit low-power applications with varying load conditions, like portable electronics and LED drivers, due to their simpler control and lower switching losses at light loads. Selecting CCM or DCM depends on factors like load current, efficiency priorities, and noise sensitivity in the specific application scenario.

EMI and Noise Performance in CCM vs DCM

CCM (Continuous Conduction Mode) boost converters typically exhibit lower EMI and noise levels compared to DCM (Discontinuous Conduction Mode) due to more stable current flow and reduced switching stress. The continuous inductor current in CCM minimizes high-frequency noise spikes, resulting in improved electromagnetic compatibility and smoother output voltage ripple. In contrast, DCM operation generates higher peak currents and abrupt switching transitions, leading to increased EMI emissions and noise disturbances.

Summary: Choosing the Right Boost Mode for Your Design

CCM boost converters maintain continuous inductor current, offering lower ripple and improved efficiency at higher loads, making them ideal for stable power supply designs. DCM boost converters allow inductor current to drop to zero, resulting in simpler control and better performance at light loads, suited for designs prioritizing cost and simplicity. Selecting the appropriate boost mode depends on load conditions, efficiency targets, and complexity tolerance to optimize power delivery and device lifespan.

CCM boost vs DCM boost Infographic

electrown.com

electrown.com