Flyback converters provide isolated voltage conversion with energy stored temporarily in a transformer, making them ideal for low-power applications and complex load requirements. Understanding the differences in efficiency, component complexity, and use cases between flyback and forward converters will help you choose the right solution for your power supply needs--read on to explore these critical distinctions.

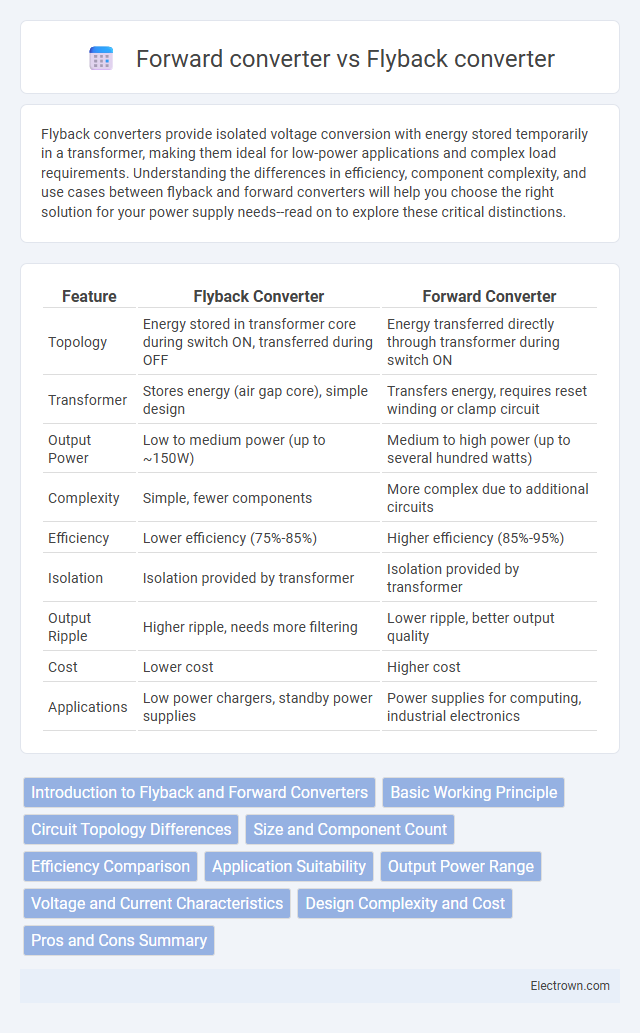

Table of Comparison

| Feature | Flyback Converter | Forward Converter |

|---|---|---|

| Topology | Energy stored in transformer core during switch ON, transferred during OFF | Energy transferred directly through transformer during switch ON |

| Transformer | Stores energy (air gap core), simple design | Transfers energy, requires reset winding or clamp circuit |

| Output Power | Low to medium power (up to ~150W) | Medium to high power (up to several hundred watts) |

| Complexity | Simple, fewer components | More complex due to additional circuits |

| Efficiency | Lower efficiency (75%-85%) | Higher efficiency (85%-95%) |

| Isolation | Isolation provided by transformer | Isolation provided by transformer |

| Output Ripple | Higher ripple, needs more filtering | Lower ripple, better output quality |

| Cost | Lower cost | Higher cost |

| Applications | Low power chargers, standby power supplies | Power supplies for computing, industrial electronics |

Introduction to Flyback and Forward Converters

Flyback and Forward converters are fundamental topologies in switch-mode power supplies, each designed for efficient voltage regulation and isolation. A Flyback converter stores energy in a transformer during the switch-on period and releases it to the output when the switch is off, making it suitable for low to medium power applications. Forward converters transfer energy directly to the output during the switch-on phase with improved efficiency and lower output voltage ripple, commonly used in higher power designs.

Basic Working Principle

Flyback converters store energy in a transformer during the switch-on phase and release it to the output during the switch-off phase, making them ideal for isolated, low-power applications. Forward converters transfer energy directly from input to output during the switch-on period using a transformer, providing higher efficiency and continuous current supply. Understanding your power requirements helps determine which topology best suits your application's basic working principle.

Circuit Topology Differences

Flyback converters utilize a single magnetic component that functions as both an energy storage and transfer element, incorporating a transformer with an air gap to store energy during the switch-on period and release it when off, enabling isolation and multiple output voltages. Forward converters use a transformer to transfer energy directly from the input to the output during the switch-on period, requiring additional components like inductors and rectifiers to smooth the output and reset the transformer core. The fundamental topology difference lies in energy storage: flyback stores energy in the magnetic field, whereas forward transfers energy directly, impacting complexity, efficiency, and suitability for different power levels.

Size and Component Count

Flyback converters typically feature a simpler design with fewer components, resulting in a smaller overall size suitable for low-power applications. Forward converters generally require more components, including an output inductor and more complex transformer construction, which increases their size but enables higher efficiency at medium power levels. Your choice between the two should consider the trade-off between compactness with flyback and performance with forward converters.

Efficiency Comparison

Flyback converters typically exhibit lower efficiency, ranging from 70% to 85%, due to energy storage and transfer losses in the transformer and higher switching losses. Forward converters achieve higher efficiencies between 80% and 90% by directly transferring energy to the output during the switch-on period, minimizing energy dissipation. For your power supply design, choosing a forward converter can optimize energy savings and thermal management in high-load applications.

Application Suitability

Flyback converters are ideal for low to medium power applications up to around 150W, particularly in isolated power supplies for devices such as chargers, small appliances, and industrial instrumentation. Forward converters excel in medium to high power ranges, typically above 150W, making them suitable for applications like telecom power supplies, computer power units, and LED drivers where higher efficiency and lower output voltage ripple are critical. The choice between flyback and forward converters depends on power requirements, complexity, and efficiency needs specific to the target application.

Output Power Range

Flyback converters typically handle low to medium output power ranges, generally up to 150 watts, making them ideal for applications requiring isolated power with simple design and cost-effectiveness. Forward converters support higher output power levels, often ranging from 50 watts to several hundred watts, suitable for more demanding applications requiring greater efficiency and continuous energy transfer. Your choice depends on the required output power, with Flyback suited for low-power designs and Forward converters better for medium to high-power implementations.

Voltage and Current Characteristics

Flyback converters feature discontinuous current, leading to higher peak currents but allowing simple isolation and voltage step-up or step-down with a single transformer winding, making them suitable for low to medium power applications. Forward converters provide continuous current with lower peak current stress on components, enabling higher efficiency and better performance in medium to high power levels by using multiple transformer windings or reset mechanisms. Voltage in flyback converters is determined by the magnetizing inductance and switching frequency, while forward converters regulate voltage through direct energy transfer in the transformer, resulting in less voltage spike and ripple.

Design Complexity and Cost

Flyback converters feature simpler design with fewer components, making them cost-effective for low to medium power applications. Forward converters require more complex circuitry, including additional transformers and control elements, leading to higher design complexity and increased manufacturing costs. Flyback topology is preferred for compact, budget-sensitive designs, whereas forward converters suit higher power systems despite their elevated complexity and expense.

Pros and Cons Summary

Flyback converters offer simplicity and cost-effectiveness with electrical isolation, making them ideal for low to medium power applications, but suffer from limited efficiency and higher noise. Forward converters provide higher efficiency and better performance at higher power levels, yet require more complex components and design efforts. Your choice depends on power requirements, cost constraints, and efficiency priorities.

Flyback vs Forward converter Infographic

electrown.com

electrown.com