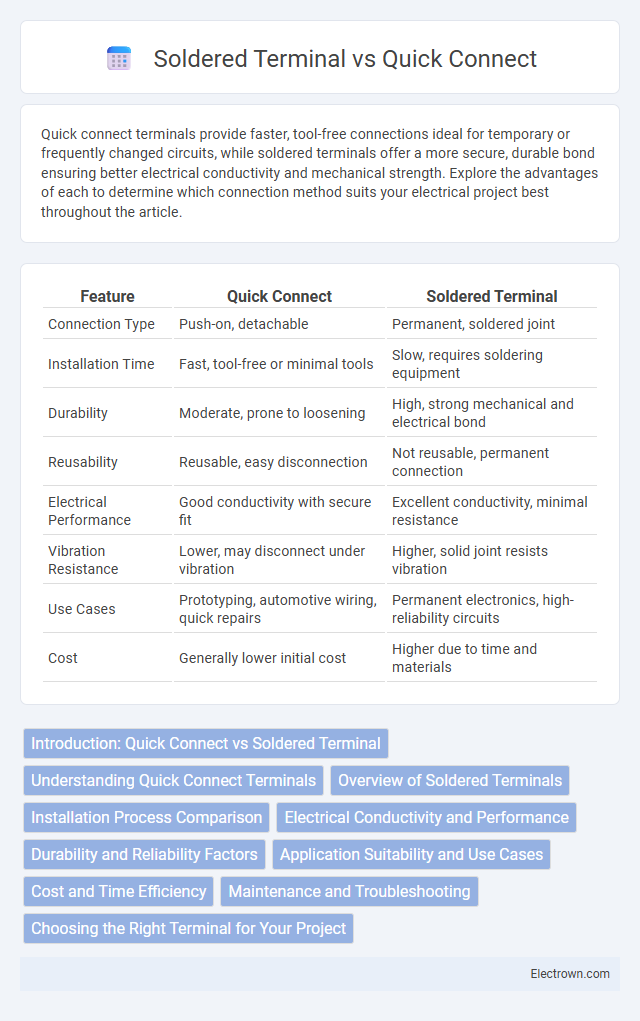

Quick connect terminals provide faster, tool-free connections ideal for temporary or frequently changed circuits, while soldered terminals offer a more secure, durable bond ensuring better electrical conductivity and mechanical strength. Explore the advantages of each to determine which connection method suits your electrical project best throughout the article.

Table of Comparison

| Feature | Quick Connect | Soldered Terminal |

|---|---|---|

| Connection Type | Push-on, detachable | Permanent, soldered joint |

| Installation Time | Fast, tool-free or minimal tools | Slow, requires soldering equipment |

| Durability | Moderate, prone to loosening | High, strong mechanical and electrical bond |

| Reusability | Reusable, easy disconnection | Not reusable, permanent connection |

| Electrical Performance | Good conductivity with secure fit | Excellent conductivity, minimal resistance |

| Vibration Resistance | Lower, may disconnect under vibration | Higher, solid joint resists vibration |

| Use Cases | Prototyping, automotive wiring, quick repairs | Permanent electronics, high-reliability circuits |

| Cost | Generally lower initial cost | Higher due to time and materials |

Introduction: Quick Connect vs Soldered Terminal

Quick connect terminals offer fast, tool-free installation and easy replacement, making them ideal for applications requiring frequent maintenance or modifications. Soldered terminals provide a permanent, reliable electrical connection with superior conductivity, ensuring long-term durability in critical circuits. Your choice depends on balancing convenience with connection stability in your specific electrical projects.

Understanding Quick Connect Terminals

Quick connect terminals provide a fast and efficient method for attaching wires to electrical components without the need for soldering, enhancing ease of installation and maintenance. These terminals use a friction fit or locking mechanism to secure wires, ensuring reliable electrical contact and minimizing the risk of damage from heat during soldering. Your choice between quick connect and soldered terminals impacts assembly speed, durability, and the feasibility of future modifications or repairs.

Overview of Soldered Terminals

Soldered terminals provide a secure and reliable electrical connection by melting solder to join wires and connectors, ensuring low resistance and high conductivity. This method is favored for applications requiring permanent connections and superior mechanical strength, resisting vibrations and environmental stress. Your electrical systems benefit from enhanced durability and longevity when using soldered terminals compared to quick connect options.

Installation Process Comparison

Quick connect terminals offer a faster and more straightforward installation process by simply snapping connectors together without requiring special tools or soldering skills. Soldered terminals demand precise heating and solder application to create a secure electrical bond, which can increase installation time and require specialized equipment. The choice between the two impacts overall project efficiency and reliability depending on the application and technician expertise.

Electrical Conductivity and Performance

Quick connect terminals offer ease of installation but may introduce higher electrical resistance compared to soldered terminals, potentially affecting conductivity and performance. Soldered terminals provide superior electrical conductivity by creating a stable, low-resistance joint that ensures consistent current flow and minimizes power loss. For optimal performance and reliability in your electrical connections, soldered terminals are generally preferred over quick connect options.

Durability and Reliability Factors

Quick connect terminals offer convenient installation but may be less durable under vibration and corrosion compared to soldered terminals, which provide a permanent, secure electrical connection with greater resistance to environmental stress. Soldered terminals ensure consistent conductivity and reliability over time by minimizing movement and oxidation risks, making them ideal for critical or high-vibration applications. Your choice should consider the operating conditions and the importance of long-term performance in your electrical setup.

Application Suitability and Use Cases

Quick connect terminals offer rapid installation and are ideal for applications requiring frequent disconnection or maintenance, such as automotive wiring and household appliances. Soldered terminals provide a more permanent, reliable electrical connection suited for high-vibration environments and critical electronic devices like circuit boards. Your choice between quick connect and soldered terminals depends on the need for ease of service versus long-term durability in specific use cases.

Cost and Time Efficiency

Quick connect terminals offer significant time efficiency by enabling rapid installation without specialized tools, reducing labor costs in assembly or maintenance. Soldered terminals, while providing a secure and permanent connection, require more time and skill to install, increasing overall labor expenses. For your projects seeking faster turnaround and cost-effective assembly, quick connect solutions often prove more economical despite slightly higher material costs.

Maintenance and Troubleshooting

Quick connect terminals simplify maintenance by enabling rapid disconnection and reconnection without specialized tools, reducing downtime during troubleshooting. Soldered terminals, while offering reliable and stable connections, require desoldering equipment and more time to inspect or replace, complicating maintenance efforts. The choice between quick connect and soldered terminals impacts ease of troubleshooting and overall efficiency in repair processes.

Choosing the Right Terminal for Your Project

Quick connect terminals offer fast installation and easy removal, ideal for projects requiring frequent maintenance or adjustments. Soldered terminals provide a more reliable and permanent connection, ensuring better conductivity and durability for long-term applications. Choosing the right terminal depends on your project's need for flexibility versus stability and longevity.

Quick connect vs Soldered terminal Infographic

electrown.com

electrown.com