An H-bridge inverter uses four switches to convert DC to AC with a simpler design ideal for low power applications, while a full-bridge inverter employs two full H-bridge circuits for higher power handling and improved waveform quality. Discover which inverter type best suits your needs by exploring the detailed comparison in the rest of the article.

Table of Comparison

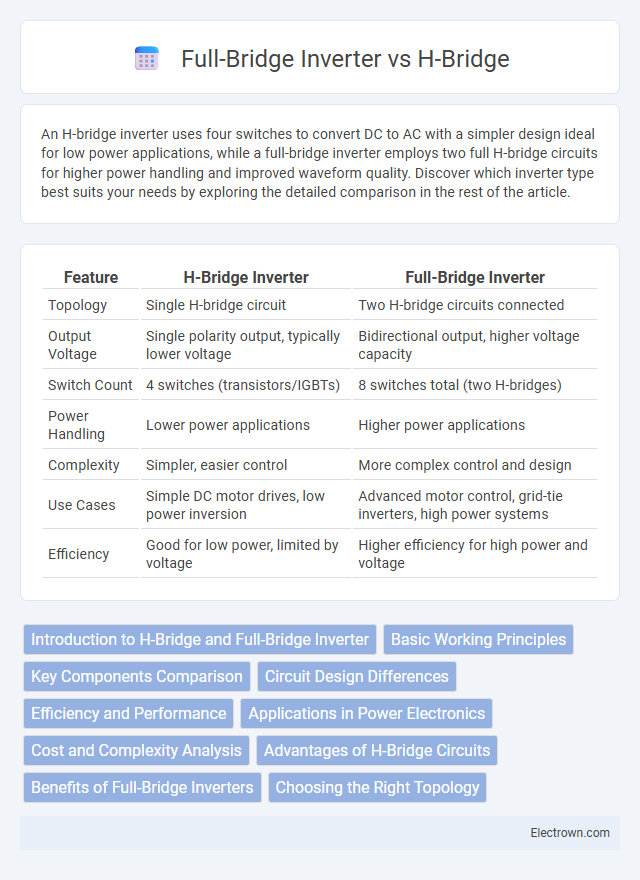

| Feature | H-Bridge Inverter | Full-Bridge Inverter |

|---|---|---|

| Topology | Single H-bridge circuit | Two H-bridge circuits connected |

| Output Voltage | Single polarity output, typically lower voltage | Bidirectional output, higher voltage capacity |

| Switch Count | 4 switches (transistors/IGBTs) | 8 switches total (two H-bridges) |

| Power Handling | Lower power applications | Higher power applications |

| Complexity | Simpler, easier control | More complex control and design |

| Use Cases | Simple DC motor drives, low power inversion | Advanced motor control, grid-tie inverters, high power systems |

| Efficiency | Good for low power, limited by voltage | Higher efficiency for high power and voltage |

Introduction to H-Bridge and Full-Bridge Inverter

H-Bridge and Full-Bridge inverters are widely utilized in converting DC to AC power with high efficiency and control. An H-Bridge inverter features four switches configured in an H-pattern, enabling bidirectional current flow for motor control and signal inversion. The Full-Bridge inverter expands on this by using two H-Bridge circuits to provide more complex waveform synthesis and higher power output capabilities for industrial applications.

Basic Working Principles

An H-bridge inverter uses four switches arranged in an H pattern to control the direction of current flow, enabling the conversion of DC to AC by alternating the output polarity. A full-bridge inverter employs a similar configuration but typically includes two H-bridge circuits working together to produce a more stable and higher voltage AC output, improving efficiency. Your choice between these inverters depends on the required voltage output and the complexity of the power conversion task.

Key Components Comparison

An H-bridge inverter primarily consists of four switches arranged in an H configuration to control the direction of current flow, enabling bidirectional voltage output, whereas a full-bridge inverter uses four switches arranged in two legs to produce a full AC waveform from a DC source. Both topologies employ transistors or IGBTs as main switching components, but the full-bridge design offers better voltage utilization and smoother output waveforms. Capacitors, diodes, and control circuits are essential in both configurations to manage switching transitions and protect against voltage spikes.

Circuit Design Differences

The primary circuit design difference between H-bridge and full-bridge inverters lies in their configurations and switching arrangements; an H-bridge inverter uses four switches arranged in an "H" pattern to control the current flow direction through a load, enabling bipolar output voltage. Full-bridge inverters also consist of four switches but typically provide better voltage utilization and waveform quality by combining two half-bridge circuits, delivering higher efficiency and smoother AC output. You should choose the inverter type based on your specific application needs, load requirements, and desired output characteristics.

Efficiency and Performance

H-bridge inverters typically offer higher efficiency in low to medium power applications due to simpler circuitry and reduced switching losses. Full-bridge inverters provide superior performance in high-power scenarios by allowing bidirectional current flow and better voltage utilization. Your choice between the two should consider the specific power requirements and efficiency demands of your application.

Applications in Power Electronics

H-bridge and full-bridge inverters are essential in power electronics for converting DC to AC in various applications such as motor drives, renewable energy systems, and uninterruptible power supplies (UPS). The H-bridge inverter is commonly used in low to medium power motor control, offering efficient bidirectional control for DC motors and small-scale energy converters. Full-bridge inverters, with their ability to deliver higher power output and improved waveform quality, are ideal for large-scale applications like industrial motor drives and grid-tied solar inverters, enabling you to achieve higher performance and reliability in your power electronics systems.

Cost and Complexity Analysis

An H-bridge inverter typically offers lower cost and simpler design due to fewer components, making it ideal for low-power applications. Full-bridge inverters, while more complex and expensive because they require more switches and control circuitry, provide improved efficiency and better waveform quality for higher-power systems. Your choice depends on balancing budget constraints with performance needs in your specific application.

Advantages of H-Bridge Circuits

H-bridge circuits offer significant advantages in simplicity, cost-effectiveness, and ease of control compared to full-bridge inverters. Their ability to efficiently switch the polarity of the output voltage makes them ideal for driving DC motors and enabling bidirectional control with fewer components. You benefit from reduced complexity while maintaining effective power conversion and precise motor control.

Benefits of Full-Bridge Inverters

Full-bridge inverters provide higher output voltage and greater power capacity compared to H-bridge inverters, making them ideal for applications requiring efficient energy conversion. They offer improved harmonic performance and reduced ripple, resulting in cleaner AC output waveform. Full-bridge inverters also enhance reliability by distributing loads evenly across four switching devices, reducing stress and increasing operational lifespan.

Choosing the Right Topology

Choosing between an H-bridge and a full-bridge inverter depends on your power requirements and efficiency goals. An H-bridge inverter is often preferred for low to medium power applications due to its simpler design and cost-effectiveness, while a full-bridge inverter provides higher power output and improved waveform quality, making it suitable for more demanding industrial uses. Understanding your load characteristics and desired efficiency will help determine the optimal inverter topology for your system.

h-bridge vs full-bridge inverter Infographic

electrown.com

electrown.com