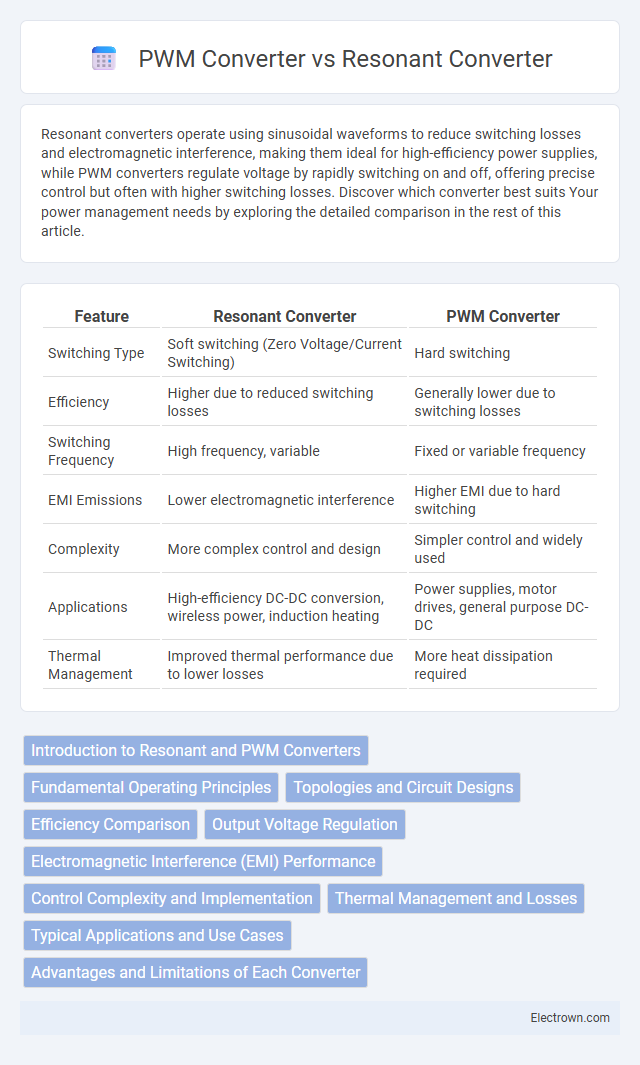

Resonant converters operate using sinusoidal waveforms to reduce switching losses and electromagnetic interference, making them ideal for high-efficiency power supplies, while PWM converters regulate voltage by rapidly switching on and off, offering precise control but often with higher switching losses. Discover which converter best suits Your power management needs by exploring the detailed comparison in the rest of this article.

Table of Comparison

| Feature | Resonant Converter | PWM Converter |

|---|---|---|

| Switching Type | Soft switching (Zero Voltage/Current Switching) | Hard switching |

| Efficiency | Higher due to reduced switching losses | Generally lower due to switching losses |

| Switching Frequency | High frequency, variable | Fixed or variable frequency |

| EMI Emissions | Lower electromagnetic interference | Higher EMI due to hard switching |

| Complexity | More complex control and design | Simpler control and widely used |

| Applications | High-efficiency DC-DC conversion, wireless power, induction heating | Power supplies, motor drives, general purpose DC-DC |

| Thermal Management | Improved thermal performance due to lower losses | More heat dissipation required |

Introduction to Resonant and PWM Converters

Resonant converters use sinusoidal waveforms and operate at resonant frequencies to achieve high efficiency and reduced switching losses in power conversion. PWM converters, or Pulse Width Modulation converters, control output voltage by varying the duty cycle of rectangular pulses, offering precise regulation and fast response. Understanding your application's requirements for efficiency, switching loss, and control precision is key to choosing between resonant and PWM converter technologies.

Fundamental Operating Principles

Resonant converters operate by switching at or near the natural resonant frequency of the circuit components, using tank circuits composed of inductors and capacitors to achieve zero-voltage or zero-current switching, minimizing switching losses and electromagnetic interference. PWM converters control output voltage by adjusting the duty cycle of fixed-frequency switching signals, relying on rapid transistor switching to regulate power delivery with higher switching losses compared to resonant topologies. Understanding these fundamental operating principles helps you choose the optimal converter based on efficiency, noise sensitivity, and application requirements.

Topologies and Circuit Designs

Resonant converters utilize soft-switching topologies such as series resonant, parallel resonant, and LLC resonant circuits to achieve high efficiency by minimizing switching losses and electromagnetic interference. PWM converters typically employ hard-switching designs like buck, boost, and full-bridge topologies, relying on pulse-width modulation for voltage regulation but experiencing higher switching losses. The resonant converter's circuit design features inductors and capacitors forming resonant tanks, enabling zero-voltage or zero-current switching, while PWM converter circuits primarily use transistors switched at fixed frequencies with duty cycle adjustments.

Efficiency Comparison

Resonant converters achieve higher efficiency than PWM converters by minimizing switching losses through zero-voltage or zero-current switching techniques, significantly reducing heat dissipation and electromagnetic interference. PWM converters, while simpler and widely used, exhibit greater switching losses due to hard-switching transitions, especially at high frequencies, impacting overall power efficiency. Optimizing resonant converters for specific load conditions leads to efficiency gains often exceeding 5-10% compared to traditional PWM converters in power electronics applications.

Output Voltage Regulation

Resonant converters provide superior output voltage regulation by operating at zero-voltage switching (ZVS), which minimizes switching losses and allows for more efficient adaptation to load variations. PWM converters regulate output voltage through fixed switching frequencies and duty cycle adjustments, which can lead to higher electromagnetic interference and increased heat dissipation under fluctuating loads. Your choice between the two should consider the specific application demands for voltage precision and efficiency under varying load conditions.

Electromagnetic Interference (EMI) Performance

Resonant converters exhibit lower electromagnetic interference (EMI) levels compared to PWM converters due to their soft-switching operation, which reduces high-frequency switching noise and voltage spikes. The sinusoidal switching transitions in resonant converters minimize EMI generation, improving compliance with strict EMI standards in sensitive electronic environments. In contrast, PWM converters, with their abrupt switching edges, often require complex filtering solutions to mitigate higher EMI emissions.

Control Complexity and Implementation

Resonant converters feature complex control strategies due to the need for precise timing and frequency adjustments to maintain resonance and optimize efficiency, requiring advanced digital signal processors or microcontrollers. PWM converters utilize simpler control schemes based on fixed switching frequencies and duty cycle modulation, enabling easier implementation and cost-effective integration. The intricacy of resonant converter control often demands more sophisticated software algorithms and sensing components compared to the straightforward, well-established control methods in PWM converters.

Thermal Management and Losses

Resonant converters typically exhibit lower switching losses and reduced electromagnetic interference due to their zero-voltage or zero-current switching characteristics, which enhance thermal management by minimizing heat generation. PWM converters, while simpler to control, often experience higher switching losses and thermal stress because of abrupt voltage and current transitions, necessitating more robust cooling solutions. Effective thermal management in resonant converters leads to improved efficiency and longer component lifespan compared to conventional PWM topologies.

Typical Applications and Use Cases

Resonant converters excel in high-efficiency applications requiring low electromagnetic interference, such as wireless power transfer, induction heating, and LED lighting systems. PWM converters are widely used in motor drives, power supplies, and voltage regulation due to their precise control and fast response capabilities. The choice between resonant and PWM converters depends on efficiency requirements, switching frequency, and application-specific constraints.

Advantages and Limitations of Each Converter

Resonant converters offer higher efficiency and reduced electromagnetic interference due to their soft-switching operation, making them ideal for high-frequency applications, but they are more complex and costly to design and control. PWM converters provide precise voltage regulation and simpler control schemes, supporting a wide range of load conditions effectively, yet they suffer from higher switching losses and increased heat generation. The choice between resonant and PWM converters depends on application requirements balancing efficiency, complexity, and thermal management.

resonant converter vs pwm converter Infographic

electrown.com

electrown.com