IGBT inverters offer higher efficiency and better performance at high voltages and currents, making them ideal for industrial applications, while MOSFET inverters excel in low-voltage, high-frequency scenarios due to faster switching speeds. Discover how choosing the right inverter can optimize Your system's performance by reading the rest of the article.

Table of Comparison

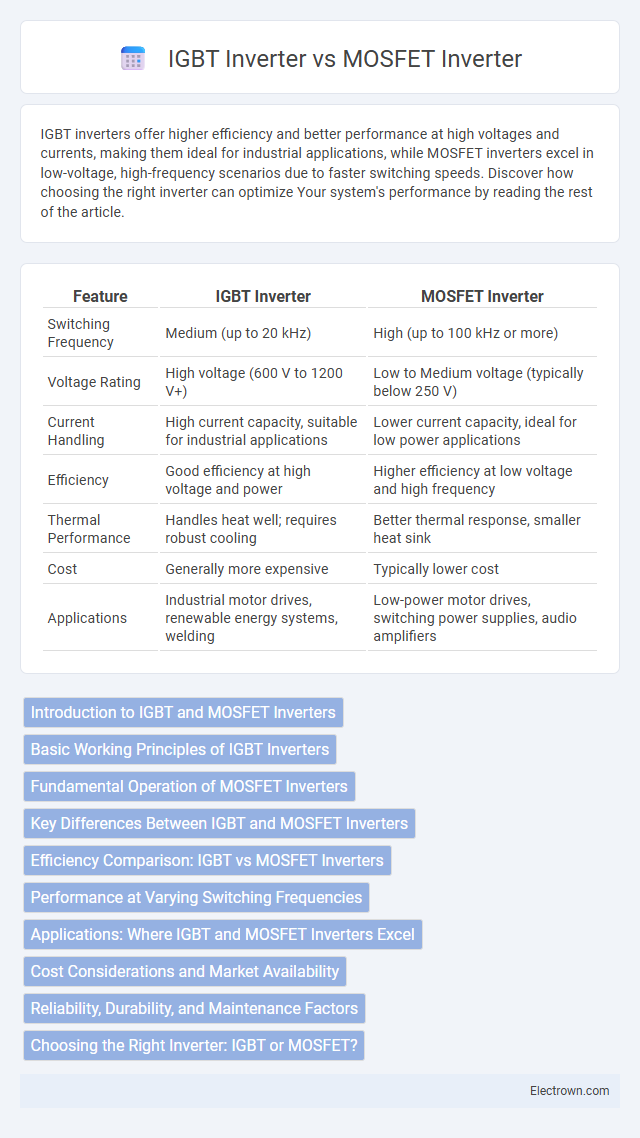

| Feature | IGBT Inverter | MOSFET Inverter |

|---|---|---|

| Switching Frequency | Medium (up to 20 kHz) | High (up to 100 kHz or more) |

| Voltage Rating | High voltage (600 V to 1200 V+) | Low to Medium voltage (typically below 250 V) |

| Current Handling | High current capacity, suitable for industrial applications | Lower current capacity, ideal for low power applications |

| Efficiency | Good efficiency at high voltage and power | Higher efficiency at low voltage and high frequency |

| Thermal Performance | Handles heat well; requires robust cooling | Better thermal response, smaller heat sink |

| Cost | Generally more expensive | Typically lower cost |

| Applications | Industrial motor drives, renewable energy systems, welding | Low-power motor drives, switching power supplies, audio amplifiers |

Introduction to IGBT and MOSFET Inverters

IGBT inverters use Insulated Gate Bipolar Transistors, ideal for high-voltage and high-current applications due to their efficient switching and low conduction losses. MOSFET inverters incorporate Metal-Oxide-Semiconductor Field-Effect Transistors, which excel in high-frequency operations and provide faster switching speeds with lower gate charge. Understanding these semiconductor devices helps you determine the right inverter technology for your specific power and frequency requirements.

Basic Working Principles of IGBT Inverters

IGBT inverters operate by combining the high-speed switching capabilities of MOSFETs with the high-current and high-voltage handling abilities of bipolar transistors, enabling efficient power conversion in applications like motor drives and renewable energy systems. They use insulated-gate bipolar transistors (IGBT) that switch electric current on and off rapidly to control the output frequency and voltage, optimizing energy flow. This blend of semiconductor features allows IGBT inverters to perform effectively at medium to high power levels with reduced switching losses compared to traditional MOSFET inverters.

Fundamental Operation of MOSFET Inverters

MOSFET inverters operate by rapidly switching Metal-Oxide-Semiconductor Field-Effect Transistors to convert DC power into AC with high efficiency and fast response times. The low on-resistance and fast switching capability of MOSFETs minimize power loss and electromagnetic interference, making them ideal for high-frequency applications. You benefit from precise control and improved thermal performance when using MOSFET inverters compared to IGBT-based systems.

Key Differences Between IGBT and MOSFET Inverters

IGBT inverters excel in handling high voltage and current applications, making them ideal for industrial and automotive uses, while MOSFET inverters offer faster switching speeds and higher efficiency suited for low-voltage and high-frequency applications like consumer electronics. The IGBT combines the high input impedance of a MOSFET with the low saturation voltage of a bipolar transistor, providing superior power handling compared to MOSFETs, which have a simpler structure and lower conduction loss. Thermal performance and switching frequency are critical differentiators, with IGBTs performing better at moderate switching frequencies and MOSFETs preferred for high-frequency operations.

Efficiency Comparison: IGBT vs MOSFET Inverters

IGBT inverters typically offer higher efficiency at high voltage and power levels due to their lower conduction losses and better thermal performance, making them ideal for industrial and large-scale applications. MOSFET inverters excel in low to medium power scenarios with faster switching speeds and lower switching losses, providing superior efficiency in compact or portable devices. Your choice depends on the specific voltage, power requirements, and efficiency priorities of your application.

Performance at Varying Switching Frequencies

IGBT inverters excel at lower switching frequencies typically below 20 kHz, offering high efficiency and robust handling of high voltage and current levels, making them ideal for industrial motor drives and heavy-duty applications. MOSFET inverters perform better at higher switching frequencies above 20 kHz due to their faster switching speed and lower gate charge, resulting in reduced switching losses and improved efficiency for applications requiring rapid frequency transitions such as precision control and low-power devices. The choice between IGBT and MOSFET inverters heavily depends on the switching frequency requirements, with MOSFETs favored for high-frequency scenarios and IGBTs preferred for high power, low-frequency contexts.

Applications: Where IGBT and MOSFET Inverters Excel

IGBT inverters excel in high-power industrial applications such as motor drives, electric vehicles, and renewable energy systems due to their ability to handle high voltage and current efficiently. MOSFET inverters are ideal for low to medium power applications like consumer electronics, small appliances, and UPS systems because of their fast switching speed and high efficiency at lower voltages. Your choice between these inverter types should depend on the power requirements and switching frequency of your specific application.

Cost Considerations and Market Availability

IGBT inverters generally have higher upfront costs compared to MOSFET inverters due to their advanced technology and higher power handling capabilities, making them suitable for medium to high power applications. MOSFET inverters offer cost advantages in low to medium power ranges, benefiting from widespread component availability and lower manufacturing expenses. Market availability favors MOSFET inverters for consumer electronics and small appliances, while IGBT inverters dominate industrial and renewable energy sectors due to their robustness and efficiency.

Reliability, Durability, and Maintenance Factors

IGBT inverters offer higher reliability and durability in high-power applications due to their ability to handle higher voltages and temperatures compared to MOSFET inverters. MOSFET inverters provide faster switching speeds and lower conduction losses, which translate to reduced thermal stress and extended component lifespan under low to medium power loads. Maintenance requirements are typically lower for IGBT inverters in heavy-duty environments, while MOSFET inverters may require more frequent inspections due to susceptibility to voltage spikes and thermal fluctuations.

Choosing the Right Inverter: IGBT or MOSFET?

Choosing the right inverter depends on your specific application requirements, with IGBT inverters excelling in high-power, high-voltage environments due to their efficient switching and thermal stability. MOSFET inverters offer faster switching speeds and better performance in low-voltage, high-frequency scenarios, making them ideal for applications requiring precise control and energy efficiency. Understanding your system's voltage and frequency demands will help you select between IGBT and MOSFET inverters for optimal reliability and performance.

igbt inverter vs mosfet inverter Infographic

electrown.com

electrown.com