TRR (Reverse Recovery Time) and TUF (Transient Undervoltage Factor) diodes differ primarily in their switching speed and voltage handling capabilities, with TRR diodes excelling in fast switching applications and TUF diodes designed to withstand transient voltage dips. Understanding these distinctions can help you choose the best diode for your circuit's performance and reliability; read on to explore their specific uses and characteristics in detail.

Table of Comparison

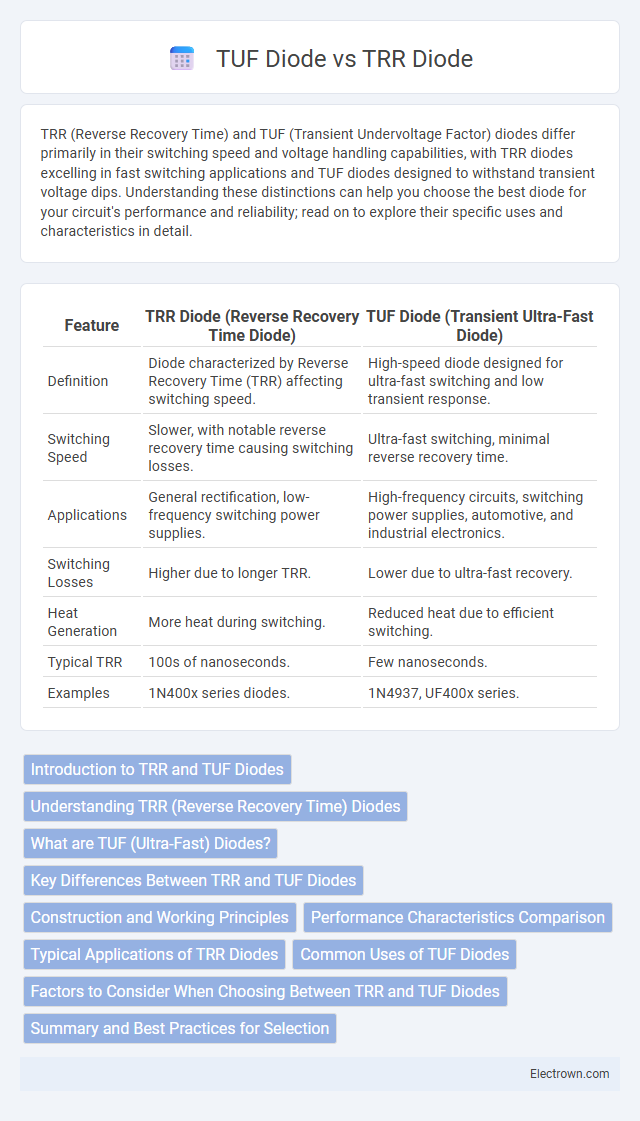

| Feature | TRR Diode (Reverse Recovery Time Diode) | TUF Diode (Transient Ultra-Fast Diode) |

|---|---|---|

| Definition | Diode characterized by Reverse Recovery Time (TRR) affecting switching speed. | High-speed diode designed for ultra-fast switching and low transient response. |

| Switching Speed | Slower, with notable reverse recovery time causing switching losses. | Ultra-fast switching, minimal reverse recovery time. |

| Applications | General rectification, low-frequency switching power supplies. | High-frequency circuits, switching power supplies, automotive, and industrial electronics. |

| Switching Losses | Higher due to longer TRR. | Lower due to ultra-fast recovery. |

| Heat Generation | More heat during switching. | Reduced heat due to efficient switching. |

| Typical TRR | 100s of nanoseconds. | Few nanoseconds. |

| Examples | 1N400x series diodes. | 1N4937, UF400x series. |

Introduction to TRR and TUF Diodes

TRR (Reverse Recovery Time) diodes are characterized by the time required for the diode to switch from conducting to blocking state, impacting switching efficiency in power circuits. TUF (Transient Ultra Fast) diodes optimize this parameter by minimizing reverse recovery time, reducing switching losses and improving performance in high-frequency applications. Your choice between TRR and TUF diodes directly affects the efficiency and thermal management in power electronics designs.

Understanding TRR (Reverse Recovery Time) Diodes

TRR (Reverse Recovery Time) is a critical parameter in diode performance, representing the time taken for the diode to switch from conducting in the forward direction to blocking in the reverse direction. Diodes with a shorter TRR reduce power loss and electromagnetic interference, making them ideal for high-speed switching applications such as inpower supplies and motor drives. Understanding TRR helps you select the appropriate diode, optimizing circuit efficiency and reliability in your electronic designs.

What are TUF (Ultra-Fast) Diodes?

TUF (Ultra-Fast) Diodes are semiconductor devices designed to switch off rapidly, minimizing reverse recovery time (trr) and reducing switching losses in high-frequency applications. These diodes exhibit recovery times typically in the range of 20 to 50 nanoseconds, making them ideal for power supplies, inverters, and motor drives. Their ultra-fast switching capability enhances efficiency and thermal performance compared to standard diodes with longer trr values.

Key Differences Between TRR and TUF Diodes

TRR (Turn-Off Reverse Recovery) diodes are designed to minimize reverse recovery time, making them ideal for high-speed switching applications, while TUF (The Ultimate Force) diodes prioritize robust durability and thermal performance in demanding environments. TRR diodes typically exhibit lower switching losses and reduced electromagnetic interference, whereas TUF diodes feature enhanced ruggedness and long-term reliability under high current and temperature stress. Understanding your application needs helps determine whether the fast recovery characteristics of TRR or the rugged endurance of TUF diodes will optimize circuit efficiency and lifespan.

Construction and Working Principles

TRR (reverse recovery time) in diodes refers to the time required for a diode to switch from conducting to blocking state, influenced by its internal charge storage. TUF diodes, designed for ruggedness and high surge current capability, utilize a robust construction with enhanced junction design to minimize TRR and improve reverse recovery performance. The working principle involves controlling charge carrier recombination to reduce switching loss, making TUF diodes suitable for high-frequency and high-power applications.

Performance Characteristics Comparison

TRR (Reverse Recovery Time) and TUF (Transient Ultra-Fast) diodes differ significantly in performance characteristics, impacting switching speed and efficiency in power applications. TRR diodes exhibit longer reverse recovery times, leading to higher switching losses and electromagnetic interference, whereas TUF diodes feature ultra-fast recovery, minimizing switching losses and improving energy efficiency. Your choice between these diodes affects overall system performance, especially in high-frequency or fast-switching circuits.

Typical Applications of TRR Diodes

TRR diodes are commonly used in applications requiring fast recovery times to minimize switching losses, such as in power supply circuits, motor drives, and high-frequency inverters. They excel in protecting semiconductor devices in situations where rapid switching occurs, ensuring efficient energy conversion and reducing electromagnetic interference. Your choice of a TRR diode can enhance the performance and reliability of circuits operating in high-speed or high-voltage switching environments.

Common Uses of TUF Diodes

TUF diodes are commonly used in power rectification, voltage regulation, and protection circuits due to their ultra-fast recovery time and low reverse recovery charge. These diodes are ideal for applications in high-frequency switching power supplies, inverters, and motor drives where rapid switching and efficiency are critical. You can rely on TUF diodes to improve performance and reduce electromagnetic interference in your electronic designs.

Factors to Consider When Choosing Between TRR and TUF Diodes

When choosing between TRR (Reverse Recovery Time) and TUF (Turbo Ultra-Fast) diodes, consider switching speed requirements, as TRR diodes have slower recovery times impacting efficiency in high-frequency circuits, while TUF diodes offer ultra-fast switching suitable for modern power electronics. Thermal performance and power dissipation also play critical roles, with TUF diodes generally providing better heat management under high loads. Your application's voltage rating and current capacity must align with the diode specifications to ensure optimal performance and longevity.

Summary and Best Practices for Selection

TRR (Reverse Recovery Time) and TUF (Transient Undervoltage Forward) diodes differ primarily in switching speed and voltage robustness, with TRR diodes optimized for fast switching and low reverse recovery losses, while TUF diodes are designed for high surge current tolerance and reliability in harsh conditions. When selecting between TRR and TUF diodes, prioritize TRR diodes for applications requiring rapid switching and minimal electromagnetic interference, such as high-frequency inverters, and choose TUF diodes for circuits exposed to high surge currents and transient overvoltages, like power supplies with heavy inductive loads. Accurate assessment of circuit transient conditions, switching frequency, and thermal management ensures optimal diode performance and longevity in the given application.

trr vs tuf diode Infographic

electrown.com

electrown.com