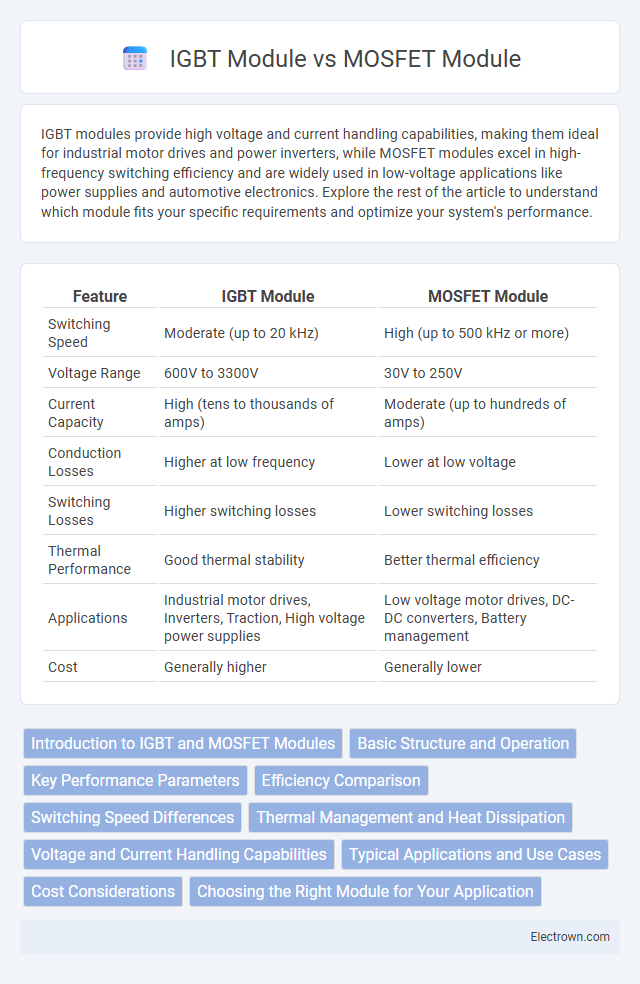

IGBT modules provide high voltage and current handling capabilities, making them ideal for industrial motor drives and power inverters, while MOSFET modules excel in high-frequency switching efficiency and are widely used in low-voltage applications like power supplies and automotive electronics. Explore the rest of the article to understand which module fits your specific requirements and optimize your system's performance.

Table of Comparison

| Feature | IGBT Module | MOSFET Module |

|---|---|---|

| Switching Speed | Moderate (up to 20 kHz) | High (up to 500 kHz or more) |

| Voltage Range | 600V to 3300V | 30V to 250V |

| Current Capacity | High (tens to thousands of amps) | Moderate (up to hundreds of amps) |

| Conduction Losses | Higher at low frequency | Lower at low voltage |

| Switching Losses | Higher switching losses | Lower switching losses |

| Thermal Performance | Good thermal stability | Better thermal efficiency |

| Applications | Industrial motor drives, Inverters, Traction, High voltage power supplies | Low voltage motor drives, DC-DC converters, Battery management |

| Cost | Generally higher | Generally lower |

Introduction to IGBT and MOSFET Modules

IGBT modules combine the high input impedance of MOSFETs with the high current and voltage handling capabilities of bipolar transistors, making them ideal for high-power applications like motor drives and inverters. MOSFET modules excel in high-speed switching and low conduction losses, suitable for low to medium power uses such as DC-DC converters and power supplies. Both modules serve distinct roles in power electronics, with IGBTs preferred for high voltage and current efficiency, while MOSFETs provide faster switching and greater efficiency at lower voltages.

Basic Structure and Operation

IGBT modules combine the bipolar junction transistor (BJT) and MOSFET structures, using a gate-controlled insulated layer to manage high voltage and current efficiently, ideal for medium to high power applications. MOSFET modules feature a single MOSFET structure with voltage-driven control and low on-resistance, making them suitable for fast switching and low voltage applications. Your choice depends on the operational needs, where IGBTs excel in high voltage and current scenarios, while MOSFETs offer superior switching speeds and efficiency at lower voltages.

Key Performance Parameters

IGBT modules excel in handling high voltage (up to 6.5 kV) and high current (thousands of amps), making them ideal for industrial motor drives and power inverters, whereas MOSFET modules offer faster switching speeds at lower voltages (typically below 250 V) and currents, suitable for switching power supplies and mobile devices. Your choice depends on key performance parameters such as switching frequency, conduction losses, and thermal management, with IGBTs providing better efficiency in high-power, low-frequency applications and MOSFETs favored for high-frequency, low-voltage environments. Thermal resistance, gate drive requirements, and ruggedness also influence the decision between these semiconductor modules based on application-specific needs.

Efficiency Comparison

IGBT modules typically offer higher efficiency at high voltage and current levels due to lower conduction losses, making them ideal for industrial applications like motor drives and inverters. MOSFET modules excel in low-voltage, high-frequency operations with faster switching speeds and reduced switching losses, enhancing efficiency in applications such as DC-DC converters and power supplies. Your choice between IGBT and MOSFET modules should consider the specific voltage, current, and switching frequency requirements to maximize efficiency.

Switching Speed Differences

IGBT modules generally have slower switching speeds compared to MOSFET modules due to their bipolar conduction mechanism, which introduces tail current during turn-off. MOSFET modules excel in high-frequency applications because their unipolar channel allows faster switching with lower switching losses. When optimizing your circuit for rapid switching performance, choosing a MOSFET module can significantly enhance efficiency and reduce heat generation.

Thermal Management and Heat Dissipation

IGBT modules excel in thermal management due to their robust structure, enabling superior heat dissipation under high voltage and current conditions compared to MOSFET modules. MOSFET modules typically operate at lower voltages and frequencies, generating less heat but requiring efficient cooling solutions to prevent thermal runaway in high-power applications. Optimizing your system's thermal management by selecting the appropriate module ensures enhanced reliability and performance in demanding environments.

Voltage and Current Handling Capabilities

IGBT modules typically handle higher voltages up to 1200V or more, making them ideal for applications requiring robust voltage endurance, while MOSFET modules excel in lower voltage environments up to around 250V but offer superior fast switching and efficiency. Current handling in IGBT modules can reach several hundred amps, suitable for heavy industrial drives, whereas MOSFET modules generally manage lower current ratings but provide better thermal performance at those levels. Understanding your voltage and current needs ensures you select the optimal module for efficient power conversion and durability.

Typical Applications and Use Cases

IGBT modules excel in high-power industrial applications such as motor drives, renewable energy systems, and electric vehicles due to their ability to handle high voltages and currents efficiently. MOSFET modules are preferred in lower voltage, high-speed switching scenarios like power supplies, DC-DC converters, and RF amplifiers, offering faster switching times and higher efficiency. Your choice between IGBT and MOSFET modules depends on the specific power level, switching frequency, and thermal requirements of your application.

Cost Considerations

IGBT modules generally have higher initial costs compared to MOSFET modules due to their complex manufacturing process and robust design suitable for high-voltage applications. MOSFET modules offer cost advantages in low to medium voltage ranges because of simpler fabrication and widespread usage in consumer electronics. When choosing between IGBT and MOSFET modules, evaluating the application's voltage, current requirements, and budget constraints ensures optimal cost-effectiveness.

Choosing the Right Module for Your Application

IGBT modules excel in high-voltage, high-current applications such as industrial motor drives and renewable energy systems due to their efficient switching and thermal stability. MOSFET modules are preferred for low-voltage, high-frequency applications like power supplies and electric vehicles because of their fast switching speeds and lower conduction losses. Evaluating your application's voltage, current, switching frequency, and thermal requirements is crucial to selecting the optimal module for performance and reliability.

igbt module vs mosfet module Infographic

electrown.com

electrown.com