Silicon MOSFETs (Si MOSFETs) are widely used for general power applications due to their cost-effectiveness and well-established manufacturing process, while Silicon Carbide MOSFETs (SiC MOSFETs) offer superior efficiency, higher temperature tolerance, and faster switching speeds, making them ideal for high-performance and industrial uses. To understand which technology best suits Your needs, explore the detailed comparison in the rest of the article.

Table of Comparison

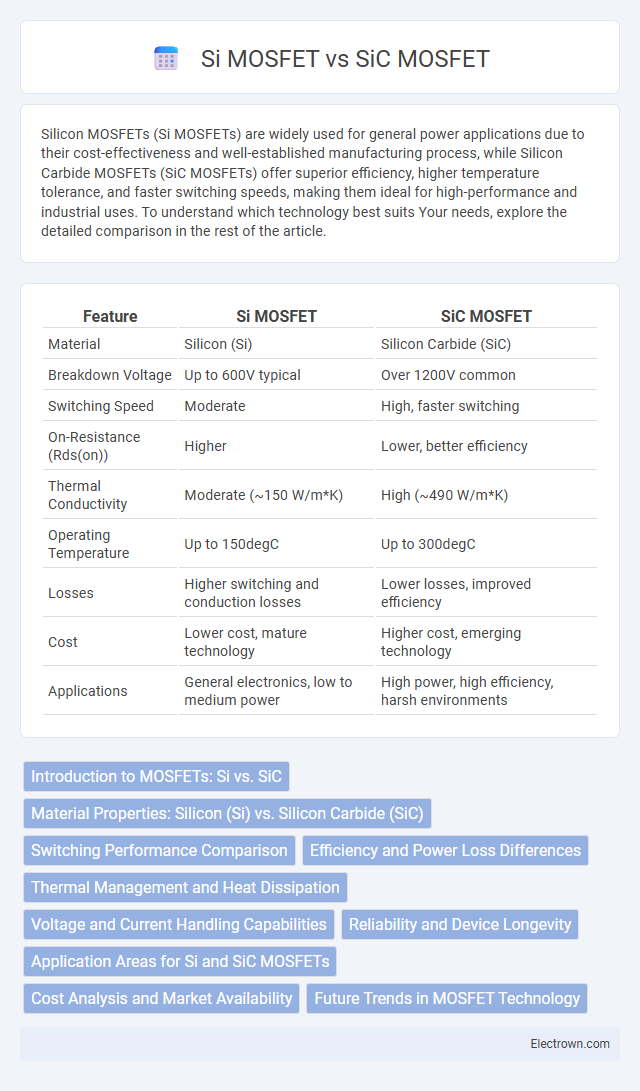

| Feature | Si MOSFET | SiC MOSFET |

|---|---|---|

| Material | Silicon (Si) | Silicon Carbide (SiC) |

| Breakdown Voltage | Up to 600V typical | Over 1200V common |

| Switching Speed | Moderate | High, faster switching |

| On-Resistance (Rds(on)) | Higher | Lower, better efficiency |

| Thermal Conductivity | Moderate (~150 W/m*K) | High (~490 W/m*K) |

| Operating Temperature | Up to 150degC | Up to 300degC |

| Losses | Higher switching and conduction losses | Lower losses, improved efficiency |

| Cost | Lower cost, mature technology | Higher cost, emerging technology |

| Applications | General electronics, low to medium power | High power, high efficiency, harsh environments |

Introduction to MOSFETs: Si vs. SiC

Silicon (Si) MOSFETs have been the standard in power electronics due to their established manufacturing processes and cost-effectiveness, offering reliable switching performance for many applications. Silicon Carbide (SiC) MOSFETs provide superior thermal conductivity, higher breakdown voltage, and faster switching speeds, making them ideal for high-power, high-temperature environments. Your choice between Si and SiC MOSFETs depends on the specific power efficiency, thermal management, and performance requirements of your electronic system.

Material Properties: Silicon (Si) vs. Silicon Carbide (SiC)

Silicon Carbide (SiC) MOSFETs exhibit higher thermal conductivity (approximately 3.7 W/cm*K) compared to Silicon (Si) MOSFETs (around 1.5 W/cm*K), enabling superior heat dissipation and higher temperature operation. SiC features a wider bandgap (~3.26 eV) than Si (~1.12 eV), resulting in lower leakage currents and improved efficiency at high voltages and frequencies. The higher electric field breakdown strength of SiC (around 2-3 MV/cm) versus Si (approximately 0.3 MV/cm) allows for reduced device sizes and enhanced power density in semiconductor applications.

Switching Performance Comparison

Si MOSFETs exhibit moderate switching speeds but suffer higher switching losses due to their material properties, resulting in reduced efficiency in high-frequency applications. SiC MOSFETs deliver superior switching performance with faster transition times and lower energy loss, making them ideal for high-power and high-frequency environments. Your choice of SiC MOSFET can optimize efficiency and thermal management in demanding switching applications compared to traditional Si counterparts.

Efficiency and Power Loss Differences

Si MOSFETs typically exhibit higher conduction and switching losses due to silicon's inherent material properties, resulting in lower efficiency in high-frequency or high-power applications. SiC MOSFETs offer significantly reduced power losses thanks to their wider bandgap, enabling faster switching speeds and lower on-resistance, which translates into superior energy efficiency and thermal management. The efficiency improvements of SiC MOSFETs make them ideal for applications demanding high power density and reduced cooling requirements.

Thermal Management and Heat Dissipation

Si MOSFETs exhibit higher thermal resistance and lower maximum junction temperatures, limiting their performance in high-power applications due to less efficient heat dissipation. SiC MOSFETs feature superior thermal conductivity (approximately 3.7 W/cm*K compared to silicon's 1.5 W/cm*K) and can operate at junction temperatures up to 175degC or higher, enabling enhanced thermal management and reduced heat buildup. The improved heat dissipation in SiC devices results in increased reliability, smaller cooling system requirements, and higher power density in automotive and industrial applications.

Voltage and Current Handling Capabilities

Si MOSFETs typically handle voltages up to 600V and currents in the range of tens to hundreds of amperes, suitable for general-purpose applications. SiC MOSFETs excel with voltage ratings exceeding 1200V and current capacities often surpassing those of Si counterparts, making them ideal for high-power and high-efficiency scenarios. Your choice depends on the voltage and current requirements of the application, with SiC providing superior performance in demanding environments.

Reliability and Device Longevity

Si MOSFETs offer established reliability with decades of proven performance in various applications, but they tend to experience more degradation under high temperature and voltage stress compared to SiC MOSFETs. SiC MOSFETs provide superior device longevity due to their wide bandgap properties, which enable higher thermal stability, reduced on-resistance, and better tolerance to harsh environments. Your choice of SiC MOSFETs can lead to longer-lasting power systems with lower failure rates and improved operational reliability.

Application Areas for Si and SiC MOSFETs

Si MOSFETs dominate low-voltage applications like consumer electronics and power supplies due to their cost-effectiveness and established manufacturing processes. SiC MOSFETs excel in high-power, high-temperature environments such as electric vehicles, renewable energy systems, and industrial motor drives because of their superior thermal conductivity and efficiency. Choosing the right device for Your application enhances performance, especially when demanding efficiency and reliability under extreme conditions.

Cost Analysis and Market Availability

Si MOSFETs generally offer lower upfront costs due to mature silicon fabrication technologies and widespread manufacturing infrastructure, making them more accessible in diverse markets. SiC MOSFETs, while more expensive initially because of complex production processes and limited suppliers, provide superior performance for high-power applications, driving growing demand despite higher prices. Your choice between Si and SiC MOSFETs should weigh immediate cost savings against long-term efficiency and reliability benefits in your specific application.

Future Trends in MOSFET Technology

Silicon Carbide (SiC) MOSFETs are rapidly advancing as the future standard in power electronics due to superior efficiency, higher thermal conductivity, and faster switching speeds compared to traditional Silicon (Si) MOSFETs. Emerging trends emphasize wide adoption of SiC devices in electric vehicles, renewable energy systems, and high-frequency industrial applications, driven by the need for energy-efficient and compact power solutions. Research is focusing on improving SiC defect density, cost reduction, and enhancing reliability to further accelerate market penetration.

si mosfet vs sic mosfet Infographic

electrown.com

electrown.com