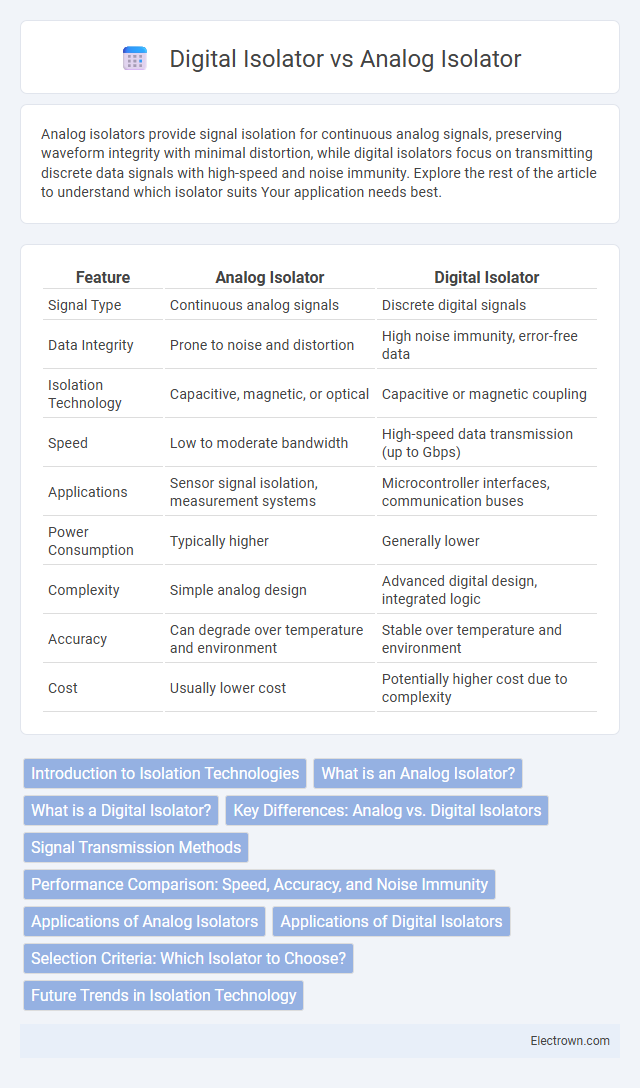

Analog isolators provide signal isolation for continuous analog signals, preserving waveform integrity with minimal distortion, while digital isolators focus on transmitting discrete data signals with high-speed and noise immunity. Explore the rest of the article to understand which isolator suits Your application needs best.

Table of Comparison

| Feature | Analog Isolator | Digital Isolator |

|---|---|---|

| Signal Type | Continuous analog signals | Discrete digital signals |

| Data Integrity | Prone to noise and distortion | High noise immunity, error-free data |

| Isolation Technology | Capacitive, magnetic, or optical | Capacitive or magnetic coupling |

| Speed | Low to moderate bandwidth | High-speed data transmission (up to Gbps) |

| Applications | Sensor signal isolation, measurement systems | Microcontroller interfaces, communication buses |

| Power Consumption | Typically higher | Generally lower |

| Complexity | Simple analog design | Advanced digital design, integrated logic |

| Accuracy | Can degrade over temperature and environment | Stable over temperature and environment |

| Cost | Usually lower cost | Potentially higher cost due to complexity |

Introduction to Isolation Technologies

Isolation technologies protect electronic circuits by preventing direct electrical connection while allowing signal transmission. Analog isolators use continuous signal modulation techniques such as capacitive or magnetic coupling for linear signal transfer, ideal for sensor and audio applications. Digital isolators employ high-speed digital signals with methods like capacitive or optical coupling to transmit discrete data, providing enhanced noise immunity and faster data rates in communication systems.

What is an Analog Isolator?

An analog isolator is a device that transmits analog signals across an isolation barrier without electrical connection, ensuring signal integrity while protecting against high voltage surges and noise interference. It typically uses capacitive, optical, or magnetic coupling techniques to maintain continuous and accurate analog signal transmission. Analog isolators are vital in applications requiring precise measurement and control in industrial automation, medical instrumentation, and power electronics.

What is a Digital Isolator?

A digital isolator is an integrated circuit designed to transmit digital signals across electrical isolation barriers using capacitive or magnetic coupling, ensuring high-speed data transfer with minimal signal distortion. Unlike analog isolators, which handle continuous analog signals, digital isolators are optimized for discrete digital signals, offering improved noise immunity and lower power consumption. These devices are critical in applications requiring galvanic isolation for safety and signal integrity, such as industrial automation and medical equipment.

Key Differences: Analog vs. Digital Isolators

Analog isolators transmit continuous signals while maintaining signal integrity, making them ideal for sensor and audio applications where fidelity is crucial. Digital isolators use pulse-based data transmission to provide fast, noise-immune communication in digital circuits, offering higher speed and integration flexibility. Your choice depends on whether signal accuracy or data throughput is the primary requirement for your electronic system.

Signal Transmission Methods

Analog isolators use continuous voltage or current signals to transmit information across isolated barriers, preserving the waveform's integrity for applications like sensor data or audio signals. Digital isolators rely on high-speed digital pulses, often employing capacitive, magnetic, or optical coupling techniques to achieve fast, noise-immune signal transmission in microcontroller or communication interfaces. Your choice between analog and digital isolators depends on the nature of the signal being transmitted and the required speed, accuracy, and isolation level.

Performance Comparison: Speed, Accuracy, and Noise Immunity

Analog isolators provide superior accuracy and noise immunity for continuous signal transmission, making them ideal for sensitive sensor applications, while digital isolators excel in speed and data integrity for high-frequency signal isolation. Digital isolators offer faster data rates, often exceeding tens of Mbps, with robust electromagnetic interference (EMI) resistance due to digital signaling techniques. Your choice depends on whether high-speed communication or precise analog signal fidelity is most critical for your system's performance.

Applications of Analog Isolators

Analog isolators are commonly used in medical equipment, industrial automation, and sensor signal transmission where preserving the integrity of analog signals is crucial. These isolators effectively protect sensitive components from high voltage surges and ground loops while maintaining signal accuracy for precise measurement and control. Your application benefits from their ability to provide noise-free isolation in environments requiring continuous analog data monitoring.

Applications of Digital Isolators

Digital isolators are widely used in applications requiring high-speed, noise-immune data transmission between circuits operating at different voltage levels, such as industrial automation, medical devices, and communication systems. They enable safe signal isolation in microcontroller-to-sensor interfaces, power electronics, and motor control by providing galvanic isolation without compromising signal integrity. Their capability to support high data rates and low propagation delay makes them ideal for digital communication buses like SPI, UART, and USB.

Selection Criteria: Which Isolator to Choose?

When selecting between an analog isolator and a digital isolator, consider the signal type and application requirements; analog isolators are ideal for continuous, real-time signals like audio or sensor data, while digital isolators excel in high-speed, discrete signal transmission. Your choice depends on factors such as bandwidth, noise immunity, power consumption, and isolation voltage ratings. Evaluate the isolation distance and communication protocol compatibility to ensure optimal performance and system reliability.

Future Trends in Isolation Technology

Future trends in isolation technology emphasize increased integration of analog and digital isolators to enhance performance in mixed-signal environments. Advances in silicon photonics and capacitive coupling aim to improve data transfer rates, reduce power consumption, and offer higher isolation voltages. Your choice of isolation technology will need to consider these innovations for applications demanding greater reliability and faster signal integrity.

analog isolator vs digital isolator Infographic

electrown.com

electrown.com