IGBTs offer faster switching speeds and higher efficiency compared to SCRs, making them ideal for modern power electronics applications. Explore the rest of the article to understand which device suits your specific power control needs best.

Table of Comparison

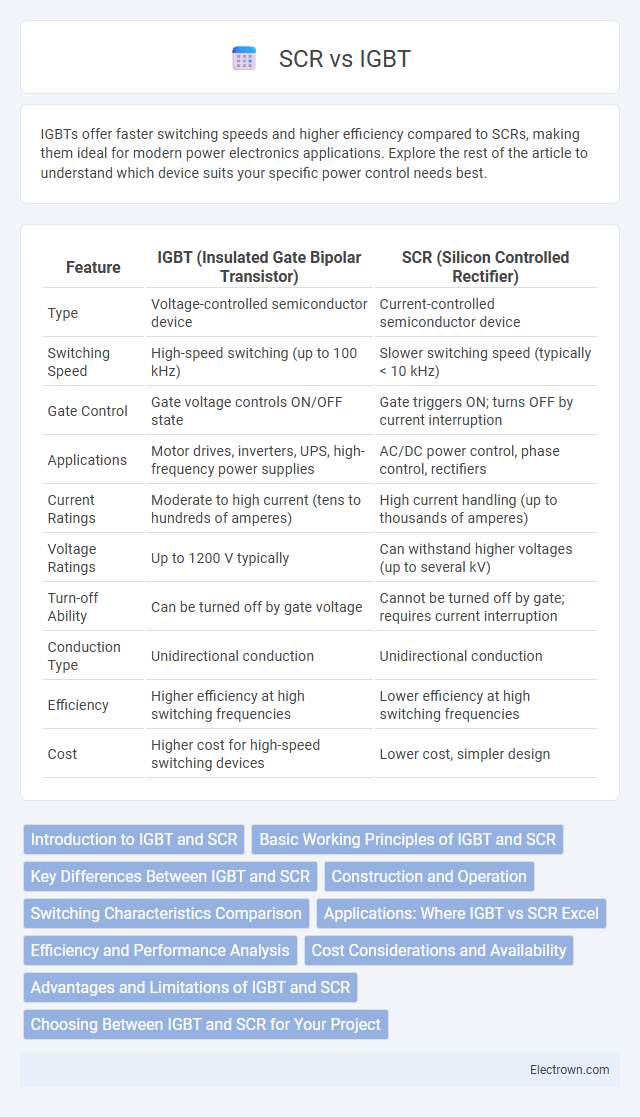

| Feature | IGBT (Insulated Gate Bipolar Transistor) | SCR (Silicon Controlled Rectifier) |

|---|---|---|

| Type | Voltage-controlled semiconductor device | Current-controlled semiconductor device |

| Switching Speed | High-speed switching (up to 100 kHz) | Slower switching speed (typically < 10 kHz) |

| Gate Control | Gate voltage controls ON/OFF state | Gate triggers ON; turns OFF by current interruption |

| Applications | Motor drives, inverters, UPS, high-frequency power supplies | AC/DC power control, phase control, rectifiers |

| Current Ratings | Moderate to high current (tens to hundreds of amperes) | High current handling (up to thousands of amperes) |

| Voltage Ratings | Up to 1200 V typically | Can withstand higher voltages (up to several kV) |

| Turn-off Ability | Can be turned off by gate voltage | Cannot be turned off by gate; requires current interruption |

| Conduction Type | Unidirectional conduction | Unidirectional conduction |

| Efficiency | Higher efficiency at high switching frequencies | Lower efficiency at high switching frequencies |

| Cost | Higher cost for high-speed switching devices | Lower cost, simpler design |

Introduction to IGBT and SCR

Insulated Gate Bipolar Transistors (IGBTs) combine the advantages of MOSFETs and bipolar transistors, providing high efficiency and fast switching in power electronics applications such as motor drives and inverters. Silicon Controlled Rectifiers (SCRs), or thyristors, are robust semiconductor devices primarily used for high voltage and high current control in applications like AC power control and rectification. Both IGBTs and SCRs play crucial roles in power conversion, with IGBTs favored for dynamic switching performance and SCRs preferred for their reliability in continuous conduction modes.

Basic Working Principles of IGBT and SCR

IGBT (Insulated Gate Bipolar Transistor) operates by combining the high input impedance of a MOSFET with the low saturation voltage of a bipolar transistor, allowing it to switch electrical power efficiently through a voltage-driven gate. SCR (Silicon Controlled Rectifier) functions as a four-layer semiconductor device that acts as a latch, turning on when a gate current triggers it and remaining conducting until the current drops below a holding level. Your choice between IGBT and SCR depends on the need for fast switching capabilities and control complexity in power electronics applications.

Key Differences Between IGBT and SCR

IGBT (Insulated Gate Bipolar Transistor) offers faster switching speeds and better efficiency compared to SCR (Silicon Controlled Rectifier), which is ideal for high power applications but operates slower. SCR is primarily used in AC power control and rectification, while IGBT is preferred for high-frequency switching in inverters and motor drives. The control method differs as IGBT uses voltage-driven gate control, whereas SCR relies on current-driven gate triggering for activation.

Construction and Operation

Insulated Gate Bipolar Transistors (IGBTs) combine the high input impedance of MOSFETs with the low saturation voltage of bipolar transistors, featuring a gate, collector, and emitter structure that enables fast switching through voltage-controlled operation. Silicon Controlled Rectifiers (SCRs) consist of four layers of alternating P and N-type materials forming a thyristor with an anode, cathode, and gate terminal, operating as a latching device triggered by a gate pulse and maintaining conduction until current drops below a threshold. The IGBT's layered semiconductor design supports rapid turn-on and turn-off ideal for high-frequency applications, while the SCR's layered PNPN structure is optimized for handling high voltages and currents in controlled rectification but with slower switching speeds.

Switching Characteristics Comparison

IGBTs offer faster switching speeds with lower turn-off losses compared to SCRs, making them ideal for high-frequency applications. SCRs excel in handling high voltage and current but have slower turn-on and turn-off times due to their latching behavior. Choosing between IGBT and SCR for your circuit depends on whether rapid switching or robust high-power handling is more critical for your application.

Applications: Where IGBT vs SCR Excel

Insulated Gate Bipolar Transistors (IGBTs) excel in high-speed switching applications such as electric vehicle inverters, renewable energy systems, and industrial motor drives due to their fast switching capabilities and high efficiency. Silicon Controlled Rectifiers (SCRs) are preferred in high-power, low-frequency applications like controlled rectifiers, AC power control, and induction heating systems because of their robustness and ability to handle large current loads. Choosing between IGBT and SCR depends on the application's frequency, power rating, and switching speed requirements, with IGBTs dominating in dynamic control scenarios and SCRs in static power regulation.

Efficiency and Performance Analysis

Insulated Gate Bipolar Transistors (IGBTs) exhibit higher switching speeds and better thermal efficiency compared to Silicon Controlled Rectifiers (SCRs), making them ideal for high-frequency applications. SCRs, while robust for high voltage and current handling, suffer from slower switching times and higher conduction losses, which reduce overall efficiency in dynamic performance scenarios. The superior switching efficiency and rapid turn-off capabilities of IGBTs contribute to enhanced performance in power electronics, especially in inverter and motor control systems.

Cost Considerations and Availability

IGBTs generally have higher upfront costs compared to SCRs due to their advanced semiconductor technology and efficiency benefits. SCRs remain widely available and cost-effective for high-power applications, making them a practical choice when budget constraints are critical. Your decision should weigh long-term performance gains of IGBTs against the immediate affordability and accessibility of SCRs.

Advantages and Limitations of IGBT and SCR

Insulated Gate Bipolar Transistors (IGBTs) offer fast switching speeds and high efficiency, making them ideal for high-frequency applications such as motor drives and inverters, while Silicon Controlled Rectifiers (SCRs) excel in handling high voltage and current with robust durability in power control and rectification. IGBTs have limitations in voltage blocking capability and thermal management, whereas SCRs have slower switching speeds and require external circuits for turn-off control. Choosing between IGBTs and SCRs depends on application-specific requirements including switching frequency, voltage, current ratings, and control complexity.

Choosing Between IGBT and SCR for Your Project

Selecting between IGBT (Insulated Gate Bipolar Transistor) and SCR (Silicon Controlled Rectifier) depends on factors like switching speed, voltage, and current ratings. IGBTs offer faster switching and better efficiency in high-frequency applications such as motor drives and inverters, while SCRs excel in high-power, low-frequency scenarios like controlled rectifiers and phase control. Evaluating parameters like gate control, thermal management, and application frequency ensures optimal device performance and project success.

igbt vs scr Infographic

electrown.com

electrown.com