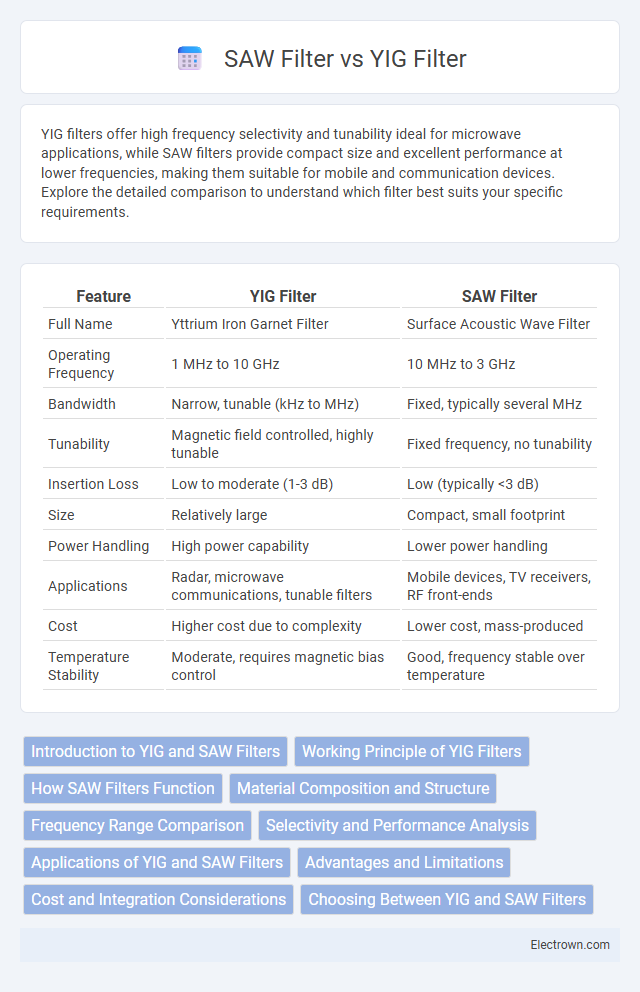

YIG filters offer high frequency selectivity and tunability ideal for microwave applications, while SAW filters provide compact size and excellent performance at lower frequencies, making them suitable for mobile and communication devices. Explore the detailed comparison to understand which filter best suits your specific requirements.

Table of Comparison

| Feature | YIG Filter | SAW Filter |

|---|---|---|

| Full Name | Yttrium Iron Garnet Filter | Surface Acoustic Wave Filter |

| Operating Frequency | 1 MHz to 10 GHz | 10 MHz to 3 GHz |

| Bandwidth | Narrow, tunable (kHz to MHz) | Fixed, typically several MHz |

| Tunability | Magnetic field controlled, highly tunable | Fixed frequency, no tunability |

| Insertion Loss | Low to moderate (1-3 dB) | Low (typically <3 dB) |

| Size | Relatively large | Compact, small footprint |

| Power Handling | High power capability | Lower power handling |

| Applications | Radar, microwave communications, tunable filters | Mobile devices, TV receivers, RF front-ends |

| Cost | Higher cost due to complexity | Lower cost, mass-produced |

| Temperature Stability | Moderate, requires magnetic bias control | Good, frequency stable over temperature |

Introduction to YIG and SAW Filters

YIG filters utilize yttrium iron garnet spheres controlled by magnetic fields to provide tunable microwave filtering with high Q-factors, ideal for radio frequency applications requiring precise frequency selection. SAW filters, based on surface acoustic wave technology, convert electrical signals into mechanical waves on a piezoelectric substrate, enabling compact, low-cost filtering primarily used in mobile communications. Your choice depends on application needs: YIG filters excel in tunability and selectivity, while SAW filters offer integration and mass production advantages.

Working Principle of YIG Filters

Yttrium Iron Garnet (YIG) filters operate based on the magnetic resonance properties of YIG spheres, where an external magnetic field tunes the resonant frequency by adjusting the spin wave modes. This tunability allows YIG filters to achieve high selectivity and wide frequency coverage, typically from hundreds of MHz to tens of GHz, making them ideal for microwave and RF signal filtering applications. Unlike Surface Acoustic Wave (SAW) filters that rely on piezoelectric effects and fixed frequencies, YIG filters offer continuous electronic tuning, essential for agile frequency selection in communication systems.

How SAW Filters Function

SAW filters function by utilizing surface acoustic waves generated on a piezoelectric substrate to selectively filter radio frequency signals, enabling high precision and stability in signal processing. These filters convert electrical signals into mechanical waves using interdigital transducers, allowing for effective frequency discrimination in communication devices. Compared to YIG filters, SAW filters offer compact size, lower power consumption, and are ideal for fixed frequency applications in mobile and wireless technologies.

Material Composition and Structure

Yttrium Iron Garnet (YIG) filters consist of a ferrimagnetic material with a garnet crystal structure, specifically Y3Fe5O12, allowing tunable microwave frequency filtering through magnetostatic waves. Surface Acoustic Wave (SAW) filters utilize piezoelectric substrates such as quartz, lithium niobate, or lithium tantalate, where interdigital transducers convert electrical signals into surface acoustic waves for precise filtering at higher frequencies. The distinct material compositions influence their operational frequency ranges and insertion losses, with YIG filters excelling in tunable microwave bands and SAW filters optimized for fixed, high-frequency RF filtering.

Frequency Range Comparison

YIG (Yttrium Iron Garnet) filters operate efficiently in the microwave frequency range from approximately 1 GHz to 40 GHz, offering tunability and narrow bandwidth suitable for high-frequency applications. SAW (Surface Acoustic Wave) filters primarily function in the lower microwave and RF spectrum, typically from 10 MHz up to around 3 GHz, favored for compact size and fixed frequency filtering. The frequency range of YIG filters surpasses that of SAW filters, making YIG ideal for broader microwave frequency tuning, while SAW filters excel in lower frequency, stable applications.

Selectivity and Performance Analysis

YIG filters exhibit superior selectivity with narrow bandwidth and high Q-factors, making them ideal for applications requiring precise frequency tuning and rejection of adjacent channels. SAW filters offer excellent performance at high frequencies with compact size and low insertion loss but generally have wider bandwidths and lower Q-factors compared to YIG filters. The choice between YIG and SAW filters depends on the trade-off between selectivity, size, and frequency range, with YIG filters favored in microwave frequency applications and SAW filters in RF and intermediate frequency stages.

Applications of YIG and SAW Filters

YIG filters are ideal for microwave communication systems, radar, and signal processing applications due to their tunable properties and high Q-factor at GHz frequencies. SAW filters excel in mobile devices, RF front-ends, and wireless communication, offering compact size and superior performance in low-frequency signal filtering. Your choice between YIG and SAW filters depends on the operating frequency range and application-specific requirements.

Advantages and Limitations

YIG filters offer high selectivity and tunable frequency range, making them ideal for microwave applications requiring precise signal filtering, but they are bulky and expensive compared to SAW filters. SAW filters provide compact size, low cost, and excellent performance at high frequencies with low insertion loss, yet they have limited tunability and lower power handling capabilities. Your choice depends on whether you prioritize tunability and selectivity (YIG) or cost-efficiency and compactness (SAW).

Cost and Integration Considerations

YIG filters generally have higher manufacturing costs due to their complex ferrite materials and bulky design, whereas SAW filters benefit from low-cost semiconductor fabrication processes allowing mass production. Integration of SAW filters into compact RF front-end modules is more straightforward, supporting miniaturization and multi-function integration in modern communication devices. Conversely, YIG filters require larger magnetic biasing components, making them less suitable for highly integrated systems demanding low power and small footprint.

Choosing Between YIG and SAW Filters

Choosing between YIG filters and SAW filters depends on frequency range and application requirements. YIG filters offer wideband tunability from hundreds of MHz to tens of GHz with high Q factor, making them ideal for microwave and RF signal processing. SAW filters provide compact size, low cost, and excellent performance in fixed frequency applications typically below 3 GHz, commonly used in mobile and communication devices.

YIG filter vs SAW filter Infographic

electrown.com

electrown.com