D-HVIC offers a simpler, cost-effective design with reduced complexity, while V-HVIC provides enhanced efficiency and better power handling capabilities for high-performance applications. Explore the detailed comparison ahead to determine which HVIC suits Your specific needs for optimal circuit performance.

Table of Comparison

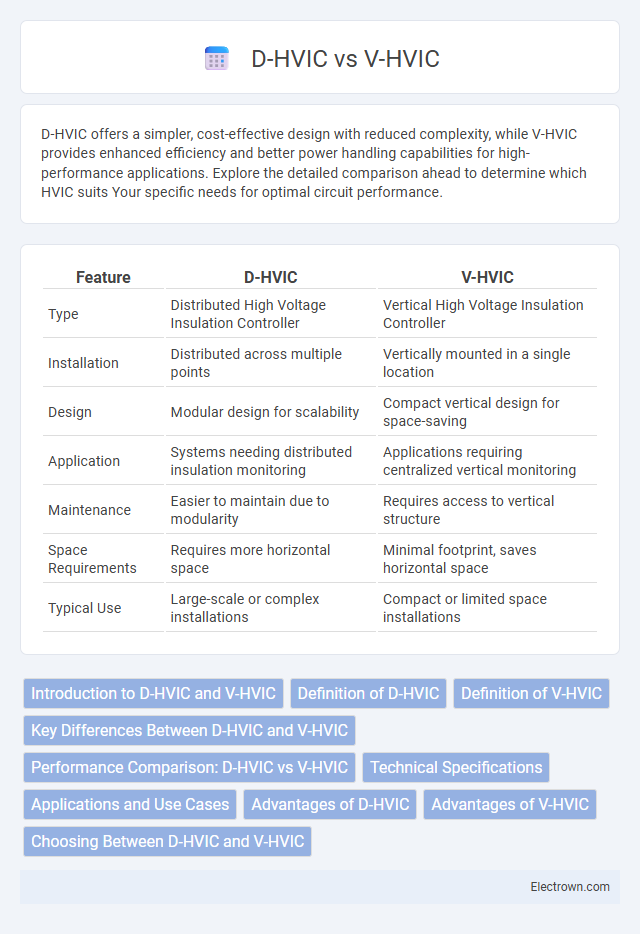

| Feature | D-HVIC | V-HVIC |

|---|---|---|

| Type | Distributed High Voltage Insulation Controller | Vertical High Voltage Insulation Controller |

| Installation | Distributed across multiple points | Vertically mounted in a single location |

| Design | Modular design for scalability | Compact vertical design for space-saving |

| Application | Systems needing distributed insulation monitoring | Applications requiring centralized vertical monitoring |

| Maintenance | Easier to maintain due to modularity | Requires access to vertical structure |

| Space Requirements | Requires more horizontal space | Minimal footprint, saves horizontal space |

| Typical Use | Large-scale or complex installations | Compact or limited space installations |

Introduction to D-HVIC and V-HVIC

D-HVIC and V-HVIC are advanced engine control systems designed to optimize valve timing for improved performance and fuel efficiency. D-HVIC (Dual Hydraulic Variable Intake Control) allows independent control of both intake valve timing and lift, while V-HVIC (Variable Hydraulic Intake Control) primarily adjusts intake valve timing. Understanding these systems enhances your knowledge of modern automotive technologies that boost engine responsiveness and reduce emissions.

Definition of D-HVIC

D-HVIC (Double-Hybrid Variable Injection Control) is a fuel injection technology designed to optimize engine performance by combining two distinct injection strategies for precise fuel delivery. This system adjusts fuel injection timing and quantity dynamically to enhance combustion efficiency, reduce emissions, and improve fuel economy compared to traditional V-HVIC (Variable Hybrid Variable Injection Control) systems. D-HVIC leverages advanced sensors and control algorithms to manage fuel-air mixture more effectively under varying engine loads and speeds.

Definition of V-HVIC

V-HVIC (Variable High Voltage Integrated Circuit) is a semiconductor technology designed to handle varying high voltage levels with enhanced efficiency and reliability in electronic systems. Compared to D-HVIC (Discrete High Voltage Integrated Circuit), V-HVIC integrates multiple voltage control functions into a single chip, reducing component count and improving circuit compactness. Understanding V-HVIC helps you optimize power management and system performance in high-voltage applications.

Key Differences Between D-HVIC and V-HVIC

D-HVIC (Distributed Hybrid Voltage and Current) and V-HVIC (Voltage-based Hybrid Voltage and Current) differ primarily in signal processing approach; D-HVIC uses distributed processing for enhanced fault tolerance, while V-HVIC relies on voltage signals for rapid fault detection. D-HVIC systems typically offer greater scalability and resilience in complex networks, whereas V-HVIC provides faster response times in voltage-sensitive environments. These distinctions impact their application in power system protection, with D-HVIC favored for large, distributed grids and V-HVIC optimized for localized voltage stability control.

Performance Comparison: D-HVIC vs V-HVIC

D-HVIC exhibits higher torque output and improved fuel efficiency compared to V-HVIC due to its dual variable valve timing system that optimizes intake and exhaust phases independently. V-HVIC, while simpler, provides moderate performance gains primarily through variable valve timing on the intake side only. Your vehicle may benefit from D-HVIC's enhanced power delivery and smoother acceleration in demanding driving conditions.

Technical Specifications

D-HVIC and V-HVIC are advanced hybrid vehicle inverter controllers designed for efficient energy management and motor control. D-HVIC typically offers a double-sided silicon carbide MOSFET configuration enabling higher switching frequencies up to 100kHz and improved thermal performance, while V-HVIC uses a vertical MOSFET arrangement optimized for ruggedness and high current capacity, often exceeding 200A in continuous operation. Your choice between D-HVIC and V-HVIC will depend on specific requirements such as switching speed, thermal efficiency, and current handling suited to your electric vehicle application.

Applications and Use Cases

D-HVIC systems excel in industrial automation and heavy machinery control due to their high voltage handling and robust performance, making them ideal for manufacturing and energy sectors. V-HVICs are primarily suited for consumer electronics and automotive applications where compact size and efficient voltage regulation are crucial. Your choice between D-HVIC and V-HVIC depends on whether your application demands high power transmission or precise low-voltage control.

Advantages of D-HVIC

D-HVIC offers superior energy efficiency by utilizing a dual hybrid valve-in-cam system that optimizes valve timing and reduces mechanical friction compared to the single V-HVIC setup. This technology enhances engine performance with improved fuel economy and lower emissions, making it ideal for modern vehicles focused on sustainability. You benefit from smoother acceleration and greater overall reliability with D-HVIC's advanced control of the intake and exhaust valves.

Advantages of V-HVIC

V-HVIC architecture offers higher switching speeds and improved power efficiency compared to D-HVIC, making it ideal for high-frequency applications. Its symmetrical layout reduces parasitic inductance, enhancing voltage handling capabilities and thermal performance. V-HVIC's compact design also supports better integration in advanced power management systems.

Choosing Between D-HVIC and V-HVIC

Choosing between D-HVIC (Dual-HVIC) and V-HVIC (Variable-HVIC) depends on your system's complexity and control requirements. D-HVIC offers enhanced redundancy and reliability by utilizing two high-voltage integrated converters, ideal for critical applications needing consistent power. V-HVIC provides flexibility and efficiency with adjustable output characteristics, making it suitable for dynamic environments where power demand varies frequently.

D-HVIC vs V-HVIC Infographic

electrown.com

electrown.com