SiC JFETs offer superior thermal stability and lower on-resistance, making them ideal for high-frequency and high-temperature applications, while SiC MOSFETs provide easier gate control and faster switching speeds, enhancing efficiency in power electronics. Explore the rest of the article to understand which semiconductor device best suits Your specific needs.

Table of Comparison

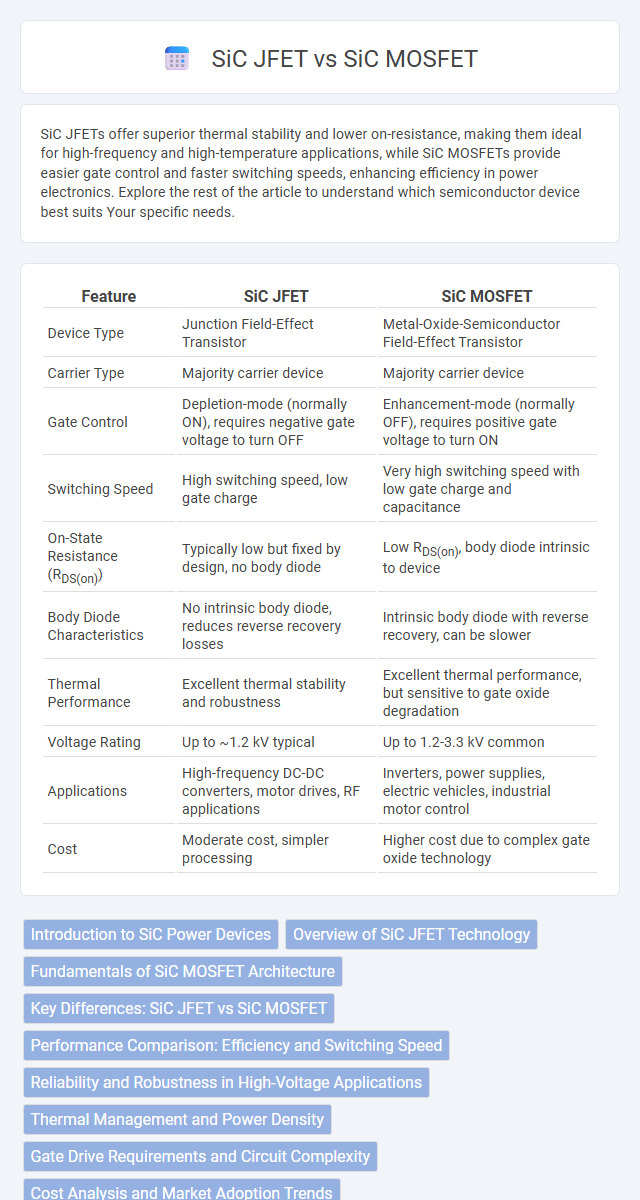

| Feature | SiC JFET | SiC MOSFET |

|---|---|---|

| Device Type | Junction Field-Effect Transistor | Metal-Oxide-Semiconductor Field-Effect Transistor |

| Carrier Type | Majority carrier device | Majority carrier device |

| Gate Control | Depletion-mode (normally ON), requires negative gate voltage to turn OFF | Enhancement-mode (normally OFF), requires positive gate voltage to turn ON |

| Switching Speed | High switching speed, low gate charge | Very high switching speed with low gate charge and capacitance |

| On-State Resistance (RDS(on)) | Typically low but fixed by design, no body diode | Low RDS(on), body diode intrinsic to device |

| Body Diode Characteristics | No intrinsic body diode, reduces reverse recovery losses | Intrinsic body diode with reverse recovery, can be slower |

| Thermal Performance | Excellent thermal stability and robustness | Excellent thermal performance, but sensitive to gate oxide degradation |

| Voltage Rating | Up to ~1.2 kV typical | Up to 1.2-3.3 kV common |

| Applications | High-frequency DC-DC converters, motor drives, RF applications | Inverters, power supplies, electric vehicles, industrial motor control |

| Cost | Moderate cost, simpler processing | Higher cost due to complex gate oxide technology |

Introduction to SiC Power Devices

SiC power devices, including SiC JFETs and SiC MOSFETs, offer superior performance in high-voltage, high-temperature, and high-frequency applications compared to silicon counterparts. SiC JFETs provide low on-resistance and robustness with normally-on operation, while SiC MOSFETs feature normally-off behavior and simpler gate drive circuitry, making them suitable for different power electronics designs. Advances in SiC technology enable enhanced efficiency and reliability in electric vehicles, renewable energy systems, and industrial motor drives.

Overview of SiC JFET Technology

SiC JFET technology offers a robust solution in power electronics with high thermal conductivity and excellent switching performance compared to traditional silicon devices. Its normally-on characteristic provides low on-resistance and fast switching speeds, making it suitable for high-efficiency applications such as inverters and motor drives. Additionally, SiC JFET devices exhibit superior robustness under high voltage and temperature conditions, enhancing overall system reliability and reducing cooling requirements.

Fundamentals of SiC MOSFET Architecture

SiC MOSFETs feature a vertical structure with a metal-oxide-semiconductor gate, enabling superior switching speeds and high-voltage capabilities compared to SiC JFETs. Their architecture includes a thin oxide layer that provides excellent gate control, reducing gate leakage and improving overall device reliability. You benefit from lower conduction losses and enhanced thermal performance in SiC MOSFETs, making them ideal for high-efficiency power electronics applications.

Key Differences: SiC JFET vs SiC MOSFET

SiC JFETs offer normally-on operation with low on-resistance and high thermal conductivity, making them ideal for high-frequency applications requiring robust switching performance. SiC MOSFETs provide normally-off operation with simpler gate drive requirements and better controllability, enhancing safety and ease of integration into your power electronics systems. The choice between SiC JFET and SiC MOSFET depends on balancing efficiency, switching speed, and system design complexity.

Performance Comparison: Efficiency and Switching Speed

SiC MOSFETs typically exhibit higher switching speeds and better efficiency at high frequencies compared to SiC JFETs, due to their unipolar conduction and lower gate charge. SiC JFETs offer excellent conduction performance with lower on-resistance but tend to have slower switching speeds than MOSFETs because of the minority carrier effects in their design. In high-power applications, SiC MOSFETs generally deliver superior overall efficiency and faster switching performance, making them suitable for demanding, high-frequency power electronics.

Reliability and Robustness in High-Voltage Applications

SiC JFETs exhibit superior reliability in high-voltage environments due to their simpler structure and absence of a gate oxide layer, which reduces susceptibility to oxide degradation and enhances robustness against high electric fields. SiC MOSFETs, while offering enhanced gate control and faster switching speeds, face challenges related to oxide reliability and threshold voltage instability under high-voltage stress. For extreme high-voltage applications above 1200V, SiC JFETs provide a more robust solution with improved long-term stability and better tolerance to avalanche and thermal stress.

Thermal Management and Power Density

SiC JFETs offer superior thermal management due to their simpler structure, which reduces heat generation and enhances reliability under high-temperature conditions. SiC MOSFETs provide higher power density, enabling more compact designs with efficient switching performance, but often require advanced cooling solutions to handle increased thermal stress. Your choice depends on balancing the need for robust heat dissipation in JFETs against the space-saving advantages of MOSFETs in high-power applications.

Gate Drive Requirements and Circuit Complexity

SiC JFETs require simpler gate drive circuits due to their normally-on nature and absence of a gate oxide layer, reducing overall circuit complexity and improving robustness against voltage spikes. SiC MOSFETs need more precise gate drive voltages with strict threshold control to prevent false switching, which increases the complexity of the drive circuitry and demands careful layout to avoid oscillations. Your choice between SiC JFET and MOSFET gate drive design hinges on balancing the simplicity and reliability of JFETs against the enhanced controllability and efficiency offered by MOSFETs.

Cost Analysis and Market Adoption Trends

SiC JFETs generally exhibit lower cost structures due to simpler fabrication processes compared to SiC MOSFETs, which require more complex gate oxide layers and processing steps. Market adoption trends indicate rising preference for SiC MOSFETs in high-performance power electronics driven by their superior switching speed and ease of gate driving, despite higher costs. Cost reductions in SiC MOSFET production and expanding application sectors such as electric vehicles and renewable energy are accelerating broader market acceptance.

Application Suitability: Choosing Between SiC JFET and MOSFET

SiC JFETs are highly suitable for high-temperature and high-voltage applications due to their low on-resistance and robust thermal stability, making them ideal for power converters and motor drives. SiC MOSFETs offer superior switching speed and lower gate drive complexity, which benefits applications requiring high-frequency operation and precise control, such as renewable energy systems and electric vehicles. Your choice should consider factors like operating temperature, switching frequency, and system complexity to optimize performance and efficiency.

SiC JFET vs SiC MOSFET Infographic

electrown.com

electrown.com