Clip packages secure components using metal clips, providing easier assembly and rework flexibility, while flat packages offer a compact, low-profile design ideal for space-constrained applications. Explore the rest of the article to discover which packaging solution best suits your electronic device needs.

Table of Comparison

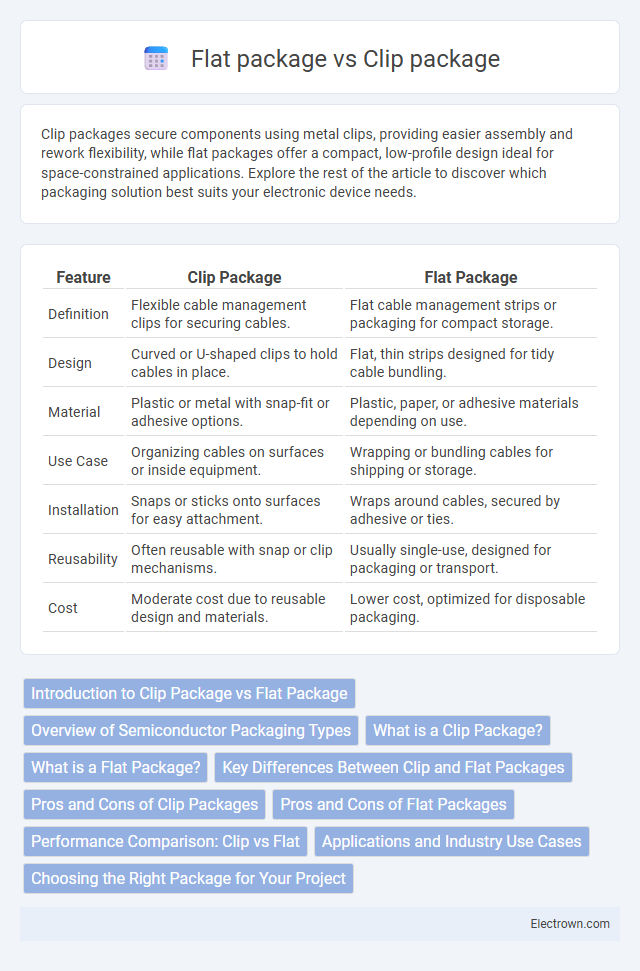

| Feature | Clip Package | Flat Package |

|---|---|---|

| Definition | Flexible cable management clips for securing cables. | Flat cable management strips or packaging for compact storage. |

| Design | Curved or U-shaped clips to hold cables in place. | Flat, thin strips designed for tidy cable bundling. |

| Material | Plastic or metal with snap-fit or adhesive options. | Plastic, paper, or adhesive materials depending on use. |

| Use Case | Organizing cables on surfaces or inside equipment. | Wrapping or bundling cables for shipping or storage. |

| Installation | Snaps or sticks onto surfaces for easy attachment. | Wraps around cables, secured by adhesive or ties. |

| Reusability | Often reusable with snap or clip mechanisms. | Usually single-use, designed for packaging or transport. |

| Cost | Moderate cost due to reusable design and materials. | Lower cost, optimized for disposable packaging. |

Introduction to Clip Package vs Flat Package

The Clip package features a raised profile and metal clips that secure the PCB, offering superior mechanical stability and improved heat dissipation compared to the Flat package's low-profile, surface-mount design. Flat packages generally provide a smaller footprint ideal for high-density circuit boards, while Clip packages excel in applications demanding robust attachment and thermal management. Selection between Clip and Flat packages depends on mechanical stress tolerance, thermal requirements, and available PCB space.

Overview of Semiconductor Packaging Types

Clip packages and flat packages are two common semiconductor packaging types designed to protect integrated circuits while facilitating electrical connections. Clip packages use metal clips for enhanced heat dissipation and mechanical stability, making them ideal for high-power applications, whereas flat packages typically feature a low-profile design with leads or pads on the bottom to optimize space and ease of mounting on PCBs. Your choice between clip and flat packages should consider thermal management needs and assembly constraints to ensure optimal device performance.

What is a Clip Package?

A Clip package is a type of semiconductor packaging where the die is mounted directly onto a metal clip or lead frame, enhancing thermal conductivity and heat dissipation. This packaging style reduces the thermal resistance between the chip and the PCB, improving reliability and performance in high-power applications. Clip packages are commonly used in power transistors, LEDs, and RF components to maintain optimal temperature control.

What is a Flat Package?

A Flat Package is a type of surface-mount electronic component packaging characterized by a rectangular or square body with leads extending from all four sides, typically bent outward for soldering. It offers a low-profile design that enhances thermal performance and mechanical stability on printed circuit boards (PCBs) compared to Clip Packages, which use metal clips for attachment. Flat Packages are widely used in integrated circuits and microcontrollers due to their compact size and efficient heat dissipation.

Key Differences Between Clip and Flat Packages

Clip packages feature leads bent into hooks that attach to the circuit, enhancing mechanical stability and allowing easier handling during assembly. Flat packages have leads extending straight out in a planar form, which offers a lower profile and better surface mount compatibility for automated soldering processes. Your choice between clip and flat packages depends on the desired mechanical strength and assembly method in your electronic design.

Pros and Cons of Clip Packages

Clip packages offer enhanced grounding and mechanical stability due to their secure metal leads, making them ideal for applications requiring strong solder joints and durability. Their rigid structure simplifies assembly and inspection but increases the package size, leading to less efficient use of PCB space compared to flat packages. However, clip packages can introduce higher parasitic inductance, potentially limiting high-frequency performance in RF or high-speed digital circuits.

Pros and Cons of Flat Packages

Flat packages offer a compact, cost-effective solution for integrated circuits, allowing for easier automated assembly and improved heat dissipation due to their low profile design. However, they can be more susceptible to physical damage and less suitable for high-pin-count applications compared to clip packages. The simpler manufacturing process of flat packages contributes to lower production costs but may compromise mechanical robustness in demanding environments.

Performance Comparison: Clip vs Flat

Clip packages generally offer better thermal performance due to their superior heat dissipation properties, making them ideal for high-power semiconductor applications. Flat packages provide a lower profile and better mechanical stability, which can reduce signal inductance and improve electrical performance in high-frequency circuits. Performance comparison between Clip and Flat packages depends on specific application requirements, balancing thermal management and electrical characteristics.

Applications and Industry Use Cases

Clip packages excel in applications requiring rapid prototyping and easy board-level upgrades, commonly used in consumer electronics and testing environments due to their accessible design. Flat packages are favored in high-density, space-constrained industries such as aerospace and medical devices, where miniaturization and reliability are critical. Both packaging types address unique industry needs: clip packages streamline development cycles, while flat packages optimize integration in compact, high-performance systems.

Choosing the Right Package for Your Project

Choosing the right package between Clip and Flat depends on your project's specific needs for size, mounting method, and electrical performance. Clip packages offer robust mechanical stability and are ideal for applications requiring secure attachment, while Flat packages provide compactness and better heat dissipation for high-density circuit designs. Your decision should consider these factors to optimize functionality and reliability in your final product.

Clip package vs Flat package Infographic

electrown.com

electrown.com