MOSFETs offer fast switching speeds and high efficiency, making them ideal for low-voltage applications, while GTOs handle higher voltage and current loads but switch slower and require complex gate drive circuits. Explore the article to understand which device best suits your power electronics needs.

Table of Comparison

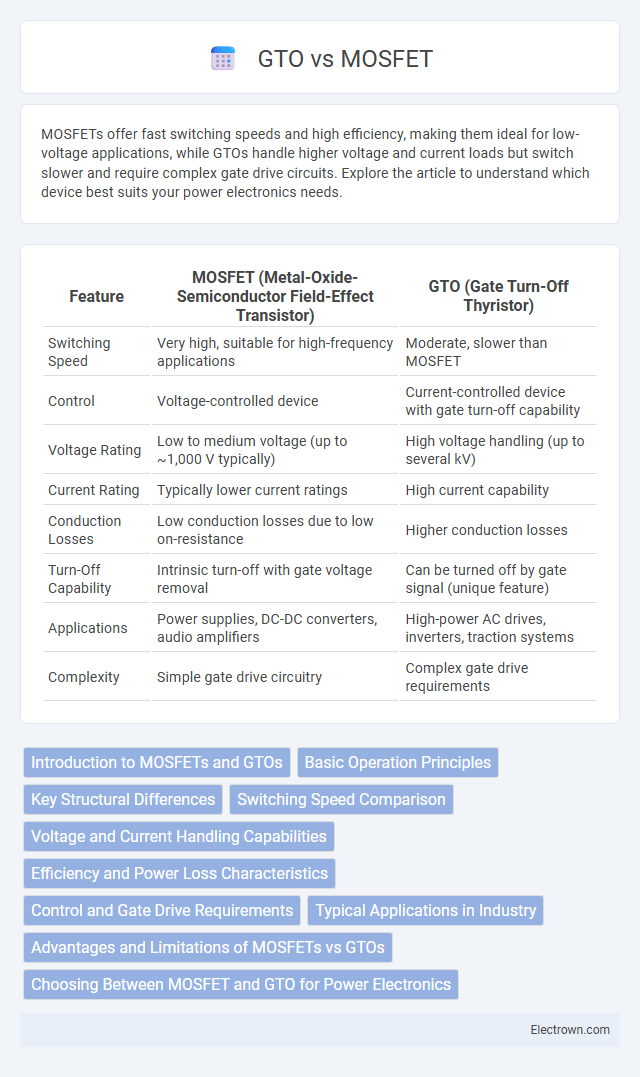

| Feature | MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) | GTO (Gate Turn-Off Thyristor) |

|---|---|---|

| Switching Speed | Very high, suitable for high-frequency applications | Moderate, slower than MOSFET |

| Control | Voltage-controlled device | Current-controlled device with gate turn-off capability |

| Voltage Rating | Low to medium voltage (up to ~1,000 V typically) | High voltage handling (up to several kV) |

| Current Rating | Typically lower current ratings | High current capability |

| Conduction Losses | Low conduction losses due to low on-resistance | Higher conduction losses |

| Turn-Off Capability | Intrinsic turn-off with gate voltage removal | Can be turned off by gate signal (unique feature) |

| Applications | Power supplies, DC-DC converters, audio amplifiers | High-power AC drives, inverters, traction systems |

| Complexity | Simple gate drive circuitry | Complex gate drive requirements |

Introduction to MOSFETs and GTOs

MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) are voltage-controlled devices widely used in low to medium power applications due to their high switching speed and efficiency. Gate Turn-Off Thyristors (GTOs) are high-power semiconductor switches designed for high voltage and current applications, offering robust turn-off capability unlike traditional thyristors. The key distinction lies in MOSFETs' rapid switching and low gate drive power compared to GTOs' ability to handle higher power levels with slower switching speeds.

Basic Operation Principles

MOSFETs operate based on voltage control where a gate voltage regulates current flow through a semiconductor channel, enabling fast switching with low on-resistance. GTOs (Gate Turn-Off Thyristors) function as current-controlled devices that can be turned on by a gate signal and turned off by a negative gate current, allowing them to handle high power levels but with slower switching speeds compared to MOSFETs. Understanding these basic operational principles helps you choose the appropriate device for applications requiring efficient switching or high power control.

Key Structural Differences

MOSFETs feature a gate insulated from the channel by a thin oxide layer, enabling voltage-controlled operation with high input impedance, while GTOs utilize a gate structure that controls the device by injecting carriers to turn off the conduction, relying on current. The MOSFET's channel is formed through an inversion layer, allowing rapid switching and low conduction losses, whereas the GTO is based on a thyristor structure with four layers (PNPN) that sustain high voltage and current but switch slower. Your choice between MOSFET and GTO hinges on these structural differences, impacting switching speed, efficiency, and control complexity in power electronics applications.

Switching Speed Comparison

MOSFETs exhibit significantly faster switching speeds compared to Gate Turn-Off Thyristors (GTOs), making them ideal for high-frequency applications. The intrinsic structure of MOSFETs allows switching in the nanosecond range, whereas GTOs typically switch in microseconds due to their thyristor-based latch mechanism. Your choice of a switching device should consider this speed difference, especially in power electronics requiring rapid switching cycles.

Voltage and Current Handling Capabilities

MOSFETs typically handle voltage ranges up to 1000V with current ratings up to several hundred amperes, making them suitable for low to medium power applications. Gate Turn-Off Thyristors (GTOs) operate efficiently at much higher voltages, often exceeding 6000V, and can handle currents in the kiloampere range, which suits high-power industrial uses. The voltage and current handling capabilities position MOSFETs for fast switching and efficiency, whereas GTOs are preferred for high-power, high-voltage environments requiring robust control.

Efficiency and Power Loss Characteristics

MOSFETs exhibit higher efficiency and lower conduction losses at low to medium voltage levels due to their low on-resistance (R_DS(on)), making them ideal for high-frequency switching applications. GTOs, while capable of handling higher voltage and current ratings, suffer from greater switching and conduction losses because of their slower turn-off times and higher forward voltage drop. The superior switching speed and lower gate drive power of MOSFETs contribute to reduced power dissipation and enhanced overall efficiency in power electronic systems.

Control and Gate Drive Requirements

MOSFETs offer simpler gate drive requirements with low voltage control signals, typically needing only a small gate-to-source voltage for switching. GTOs demand complex gate drive circuits capable of providing high amplitude negative gate current to turn off the device, increasing control complexity. The efficiency and speed of MOSFET switching outperform GTOs due to their voltage-driven gate control versus current-driven gate requirements of GTOs.

Typical Applications in Industry

MOSFETs dominate switching power supplies, motor drives, and low-voltage applications due to their high switching speeds and efficiency. GTOs are preferred in high-power industrial drives, such as traction systems and large-scale power inverters, where robust current handling and high voltage capabilities are critical. Understanding the application requirements helps you select the appropriate device for optimized performance and reliability.

Advantages and Limitations of MOSFETs vs GTOs

MOSFETs offer faster switching speeds and higher efficiency compared to GTOs, making them ideal for high-frequency applications and precise control in power electronics. However, MOSFETs typically handle lower voltage and current ratings than GTOs, which are more robust for high-power, high-voltage applications but suffer from slower switching and higher gate drive power requirements. Understanding these trade-offs helps you select the appropriate device for your specific performance and reliability needs.

Choosing Between MOSFET and GTO for Power Electronics

Choosing between MOSFET and GTO in power electronics depends on the application's voltage, current, and switching frequency requirements. MOSFETs excel in low to medium voltage applications with high switching speeds and efficiency, making them ideal for DC-DC converters and motor drives. You should select GTOs for high power, high voltage scenarios where robust control and high current handling are crucial despite slower switching speeds.

MOSFET vs GTO Infographic

electrown.com

electrown.com