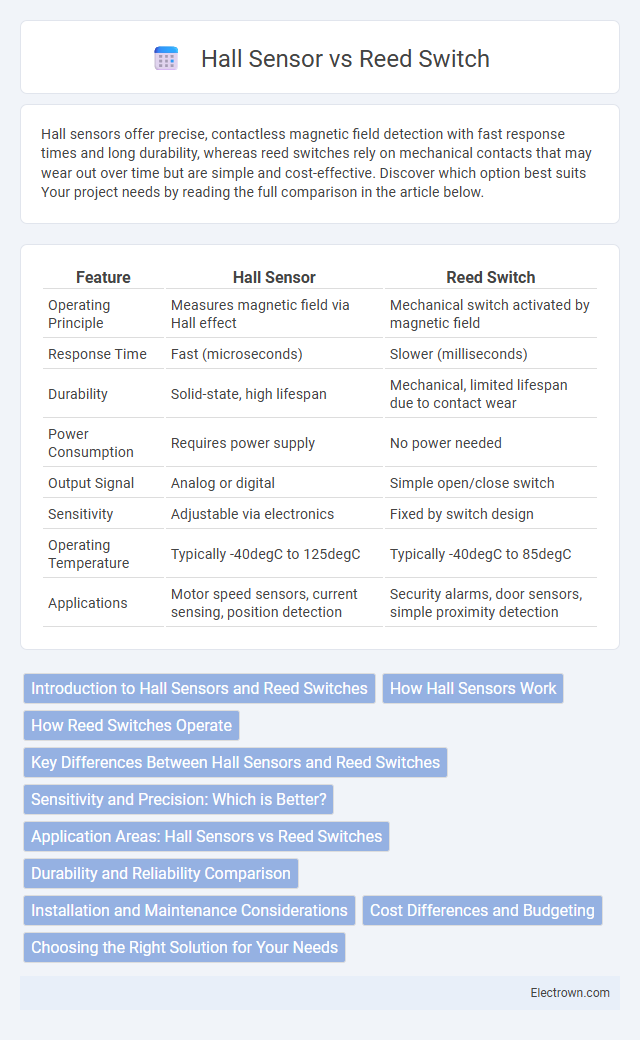

Hall sensors offer precise, contactless magnetic field detection with fast response times and long durability, whereas reed switches rely on mechanical contacts that may wear out over time but are simple and cost-effective. Discover which option best suits Your project needs by reading the full comparison in the article below.

Table of Comparison

| Feature | Hall Sensor | Reed Switch |

|---|---|---|

| Operating Principle | Measures magnetic field via Hall effect | Mechanical switch activated by magnetic field |

| Response Time | Fast (microseconds) | Slower (milliseconds) |

| Durability | Solid-state, high lifespan | Mechanical, limited lifespan due to contact wear |

| Power Consumption | Requires power supply | No power needed |

| Output Signal | Analog or digital | Simple open/close switch |

| Sensitivity | Adjustable via electronics | Fixed by switch design |

| Operating Temperature | Typically -40degC to 125degC | Typically -40degC to 85degC |

| Applications | Motor speed sensors, current sensing, position detection | Security alarms, door sensors, simple proximity detection |

Introduction to Hall Sensors and Reed Switches

Hall sensors detect magnetic fields using the Hall effect, providing contactless, precise, and fast switching suitable for speed, position, and current sensing applications. Reed switches operate with two ferrous metal reeds enclosed in a glass tube that close or open upon exposure to a magnetic field, offering a simple, low-power solution ideal for proximity and security sensing. The choice between Hall sensors and Reed switches depends on factors like sensitivity, durability, switching speed, and environmental conditions.

How Hall Sensors Work

Hall sensors operate by detecting the presence of a magnetic field through the Hall effect, where a voltage difference is generated across an electrical conductor when exposed to a magnetic field perpendicular to the current flow. Unlike reed switches that mechanically close or open contacts in response to magnetic fields, Hall sensors provide a continuous and non-contact method of measuring magnetic flux density. These sensors enable precise, reliable sensing in applications such as speed detection, position sensing, and current measurement without wear or mechanical fatigue.

How Reed Switches Operate

Reed switches operate by using two ferromagnetic blades sealed within a glass envelope that come into contact when exposed to a magnetic field, creating an electrical circuit. The contact closure is triggered by the proximity of a magnet which causes the reeds to magnetize and attract each other, enabling reliable switching without physical contact. Reed switches are valued for their simplicity, low power consumption, and high sensitivity in detecting magnetic fields.

Key Differences Between Hall Sensors and Reed Switches

Hall sensors operate using the Hall effect to detect magnetic fields, offering contactless sensing with high durability and fast response times. Reed switches rely on magnetic field-induced mechanical movement of metal reeds to open or close electrical contacts, making them susceptible to wear and slower in switching speed. Hall sensors provide continuous analog output and are more suited for precise measurements, while reed switches mainly offer binary on/off signals ideal for simple presence detection.

Sensitivity and Precision: Which is Better?

Hall sensors offer higher sensitivity and precision compared to reed switches due to their ability to detect small changes in magnetic fields with digital output and minimal contact wear. Reed switches rely on mechanical movement, which can result in slower response times and less consistent measurements over extended use. Your choice depends on the application requirements, with Hall sensors preferred for accuracy and reed switches for simple, cost-effective solutions.

Application Areas: Hall Sensors vs Reed Switches

Hall sensors are widely used in automotive systems, robotics, and consumer electronics due to their ability to provide precise, contactless position and speed sensing. Reed switches find applications in security systems, proximity sensing, and simple on/off detection tasks where low power consumption and mechanical simplicity are essential. Both technologies serve critical roles in industrial automation, but Hall sensors offer advantages in complex control systems, while reed switches excel in cost-sensitive, low-frequency switching environments.

Durability and Reliability Comparison

Hall sensors offer superior durability and reliability compared to reed switches, as they have no mechanical parts that wear out over time. Reed switches rely on physical contact between metal reeds, which can degrade due to mechanical fatigue or environmental factors like vibration and humidity. Your application benefits from the long lifespan and consistent performance of Hall sensors, especially in harsh or high-cycle environments.

Installation and Maintenance Considerations

Hall sensors offer simpler installation due to their solid-state design, requiring no physical contact or alignment with magnets, making them less prone to mechanical wear. Reed switches, reliant on mechanical contacts activated by magnetic fields, demand precise positioning and periodic inspection to ensure reliable operation, as contacts can degrade over time. Maintenance for Hall sensors is minimal, whereas reed switches may require replacement due to contact fatigue or contamination.

Cost Differences and Budgeting

Hall sensors generally come at a higher upfront cost compared to reed switches due to their advanced semiconductor technology and enhanced durability. Reed switches offer a more budget-friendly option, especially for low-volume or simple applications, but may incur higher maintenance costs over time. Your choice depends on balancing initial investment with long-term reliability and application requirements.

Choosing the Right Solution for Your Needs

Hall sensors offer precise, contactless magnetic sensing with high reliability and fast response, making them ideal for applications requiring durability and long lifespan. Reed switches, being simple mechanical devices, provide cost-effective solutions for low-power or intermittent use but may wear out faster due to physical contact. Assess your operational environment, required sensitivity, and maintenance preferences to select the solution that best aligns with your performance and budget goals.

Hall sensor vs Reed switch Infographic

electrown.com

electrown.com