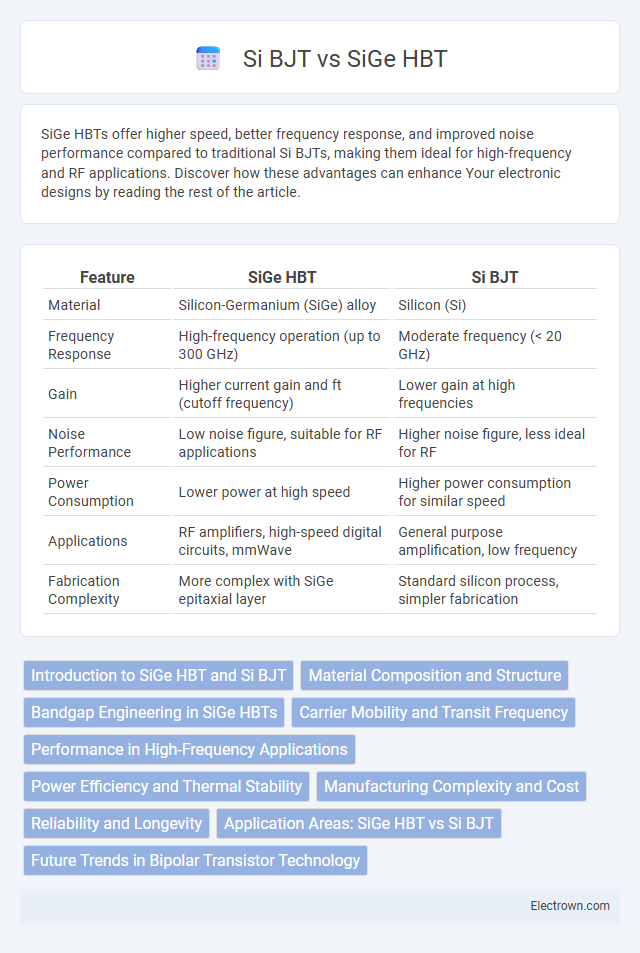

SiGe HBTs offer higher speed, better frequency response, and improved noise performance compared to traditional Si BJTs, making them ideal for high-frequency and RF applications. Discover how these advantages can enhance Your electronic designs by reading the rest of the article.

Table of Comparison

| Feature | SiGe HBT | Si BJT |

|---|---|---|

| Material | Silicon-Germanium (SiGe) alloy | Silicon (Si) |

| Frequency Response | High-frequency operation (up to 300 GHz) | Moderate frequency (< 20 GHz) |

| Gain | Higher current gain and ft (cutoff frequency) | Lower gain at high frequencies |

| Noise Performance | Low noise figure, suitable for RF applications | Higher noise figure, less ideal for RF |

| Power Consumption | Lower power at high speed | Higher power consumption for similar speed |

| Applications | RF amplifiers, high-speed digital circuits, mmWave | General purpose amplification, low frequency |

| Fabrication Complexity | More complex with SiGe epitaxial layer | Standard silicon process, simpler fabrication |

Introduction to SiGe HBT and Si BJT

SiGe HBTs (Silicon-Germanium Heterojunction Bipolar Transistors) integrate silicon and germanium to enhance carrier mobility and speed, offering superior high-frequency performance compared to traditional Si BJTs (Silicon Bipolar Junction Transistors). Si BJTs rely solely on silicon, providing reliable switching and amplification with well-established fabrication processes. Your choice between SiGe HBT and Si BJT depends on the required frequency response, power efficiency, and integration needs in high-speed analog and RF applications.

Material Composition and Structure

SiGe HBTs utilize a silicon-germanium alloy in the base region, which enhances carrier mobility and allows for higher frequency operation compared to traditional Si BJTs composed entirely of silicon. The heterojunction formed between silicon and SiGe creates a bandgap gradient, improving injection efficiency and reducing base transit time. Your choice of SiGe HBT offers superior performance in high-speed and high-frequency applications due to this advanced material composition and layered structure design.

Bandgap Engineering in SiGe HBTs

SiGe Heterojunction Bipolar Transistors (HBTs) utilize bandgap engineering by incorporating a silicon-germanium alloy in the base region, which creates a graded bandgap profile that enhances carrier injection efficiency. This bandgap grading reduces base transit time and improves high-frequency performance compared to traditional silicon Bipolar Junction Transistors (BJTs). Optimized bandgap engineering in SiGe HBTs enables higher current gain and speed, making them ideal for RF and microwave applications.

Carrier Mobility and Transit Frequency

SiGe HBTs exhibit higher carrier mobility compared to Si BJTs due to the strained silicon-germanium base, which significantly enhances electron transport efficiency. This increased carrier mobility directly contributes to a superior transit frequency (fT), allowing SiGe HBTs to achieve fT values exceeding 300 GHz, compared to typical Si BJTs with fT values around 100 GHz. Your high-frequency applications benefit from the faster switching speeds and improved performance of SiGe HBT devices.

Performance in High-Frequency Applications

SiGe HBTs exhibit superior performance in high-frequency applications compared to Si BJTs due to their higher cutoff frequency (fT) and maximum oscillation frequency (fmax), enabling faster switching speeds and improved gain at microwave frequencies. The incorporation of a SiGe heterojunction allows for reduced base transit time and enhanced charge carrier mobility, resulting in lower noise figures and better linearity. These advantages make SiGe HBTs preferred in RF front-ends, wireless communication systems, and millimeter-wave circuits where high-speed operation and signal integrity are critical.

Power Efficiency and Thermal Stability

SiGe HBTs offer superior power efficiency compared to Si BJTs due to their higher cutoff frequency and better current gain, enabling smaller, faster, and more energy-efficient circuits. They exhibit enhanced thermal stability because the SiGe heterojunction structure reduces base resistance and improves carrier transport, minimizing performance degradation under high temperature conditions. Optimizing your design with SiGe HBTs can lead to more reliable and energy-efficient applications, especially in high-frequency and high-power environments.

Manufacturing Complexity and Cost

SiGe HBTs involve more complex manufacturing processes due to the epitaxial growth of silicon-germanium layers, which requires precise temperature control and advanced equipment, increasing production costs compared to traditional Si BJTs. Silicon BJTs benefit from simpler fabrication techniques established over decades, resulting in lower manufacturing complexity and cost. Your choice between these transistors should balance performance benefits of SiGe HBTs against their higher manufacturing expense.

Reliability and Longevity

SiGe HBTs exhibit superior reliability and longevity compared to traditional Si BJTs due to their heterojunction design, which reduces base resistance and minimizes hot carrier effects. The silicon-germanium alloy in SiGe HBTs enhances thermal stability and reduces degradation over time, leading to improved device lifespan in high-frequency and high-temperature applications. Studies show that SiGe HBTs maintain performance with lower aging rates, making them ideal for long-term, reliable operation in advanced semiconductor devices.

Application Areas: SiGe HBT vs Si BJT

SiGe HBTs excel in high-frequency applications such as RF communication, radar systems, and high-speed digital circuits due to their superior speed and gain performance. Si BJTs are commonly used in low-frequency analog circuits, power amplifiers, and general-purpose switching where cost-effective, robust performance is essential. Your choice between SiGe HBT and Si BJT should align with the specific frequency, power, and integration requirements of your application area.

Future Trends in Bipolar Transistor Technology

SiGe HBTs are rapidly advancing with enhanced cutoff frequencies (fT) exceeding 500 GHz, driven by scaled-base engineering and advanced SiGe epitaxy, offering superior high-frequency performance compared to traditional Si BJTs. Future trends emphasize integrating SiGe HBTs with CMOS technology for RF front-end modules, leveraging their low noise figure and high gain for 5G and beyond wireless communication systems. Your choice of transistor technology will increasingly favor SiGe HBTs for high-speed, low-power applications due to ongoing improvements in fmax and linearity metrics.

SiGe HBT vs Si BJT Infographic

electrown.com

electrown.com