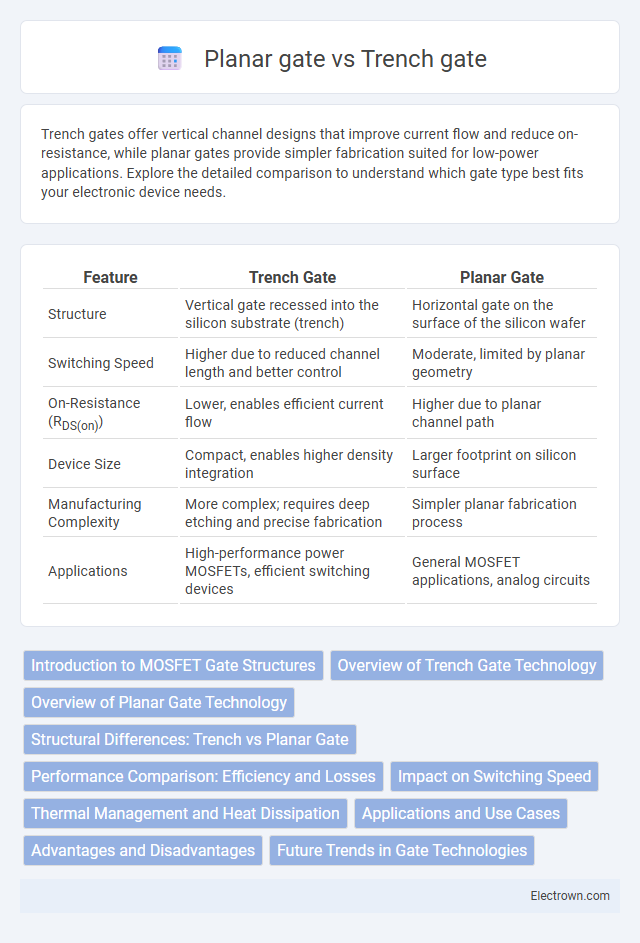

Trench gates offer vertical channel designs that improve current flow and reduce on-resistance, while planar gates provide simpler fabrication suited for low-power applications. Explore the detailed comparison to understand which gate type best fits your electronic device needs.

Table of Comparison

| Feature | Trench Gate | Planar Gate |

|---|---|---|

| Structure | Vertical gate recessed into the silicon substrate (trench) | Horizontal gate on the surface of the silicon wafer |

| Switching Speed | Higher due to reduced channel length and better control | Moderate, limited by planar geometry |

| On-Resistance (RDS(on)) | Lower, enables efficient current flow | Higher due to planar channel path |

| Device Size | Compact, enables higher density integration | Larger footprint on silicon surface |

| Manufacturing Complexity | More complex; requires deep etching and precise fabrication | Simpler planar fabrication process |

| Applications | High-performance power MOSFETs, efficient switching devices | General MOSFET applications, analog circuits |

Introduction to MOSFET Gate Structures

Trench gate and planar gate represent two fundamental MOSFET gate structures that influence device performance and fabrication complexity. Trench gate MOSFETs feature vertically oriented gates etched into the silicon substrate, enhancing channel control and reducing on-resistance. Your choice between these structures affects power efficiency and switching speed, with planar gates offering simpler manufacturing but generally higher on-resistance compared to trench designs.

Overview of Trench Gate Technology

Trench gate technology utilizes vertical channel transistors with gates embedded in etched trenches, enabling higher current density and improved switching performance compared to planar gate structures. This design reduces on-resistance and enhances device efficiency by increasing the effective channel width without expanding chip footprint. Your power electronics benefit from the superior thermal management and reliability inherent in trench gate MOSFETs, particularly in high-frequency and high-power applications.

Overview of Planar Gate Technology

Planar gate technology features a flat transistor gate structure built on the semiconductor surface, offering simple fabrication and reliable performance in traditional MOSFET devices. This technology enables efficient control of the channel region, reducing leakage currents and improving threshold voltage stability. Your choice between planar and trench gate often depends on application-specific requirements, as planar gates excel in lower power and cost-sensitive applications.

Structural Differences: Trench vs Planar Gate

Trench gate MOSFETs feature a vertical channel etched into the silicon substrate, allowing the gate electrode to wrap around the channel on multiple sides, which enhances gate control and reduces on-resistance. In contrast, planar gate MOSFETs have a horizontal channel on the wafer surface with the gate electrode positioned above, limiting electrostatic control due to the single-sided gate structure. The vertical trench design in trench MOSFETs also enables higher cell density and improved current handling compared to the planar gate structure.

Performance Comparison: Efficiency and Losses

Trench gate MOSFETs offer lower on-resistance and reduced switching losses compared to planar gate MOSFETs due to their vertical channel structure, enhancing overall efficiency in high-current applications. The compact trench design minimizes gate charge and parasitic capacitances, which significantly reduces conduction and switching losses. Planar gate devices typically exhibit higher resistance and slower switching speeds, resulting in less efficient performance under demanding power conditions.

Impact on Switching Speed

Trench gate MOSFETs exhibit faster switching speeds compared to planar gate designs due to their reduced gate charge and lower on-resistance, which significantly minimizes switching losses. The vertical channel structure in trench gates enhances charge carrier mobility and reduces gate-to-drain capacitance, directly impacting your device's efficiency in high-frequency applications. These characteristics make trench gate technology a superior choice for applications demanding rapid switching performance.

Thermal Management and Heat Dissipation

Trench gate MOSFETs offer superior thermal management compared to planar gate devices due to their vertical structure, which enables better heat dissipation through the bulk silicon substrate. The increased surface area in trench designs facilitates efficient heat transfer away from the junction, reducing thermal resistance and enhancing device reliability under high power conditions. Your choice of trench gate technology can significantly improve cooling efficiency in applications demanding high thermal performance.

Applications and Use Cases

Trench gate MOSFETs are widely used in power management applications such as DC-DC converters, motor drivers, and high-efficiency switching power supplies due to their low on-resistance and high current handling capabilities. Planar gate MOSFETs find applications in analog circuits, low-voltage switching, and integrated circuit designs where simpler fabrication and better device matching are crucial. The choice between trench and planar gate technologies depends largely on the specific performance requirements, such as breakdown voltage, switching speed, and thermal management in various electronic systems.

Advantages and Disadvantages

Trench gate MOSFETs offer lower on-resistance and higher current density compared to planar gate designs, enabling better efficiency in power applications. However, trench gates are more complex to manufacture and can suffer from reliability issues like gate oxide degradation under high stress. Your choice between trench and planar gates should consider whether performance or manufacturing simplicity is the priority for your specific application.

Future Trends in Gate Technologies

Trench gate technology offers superior electrostatic control and reduced leakage currents compared to planar gate designs, making it a preferred choice for advanced power devices in emerging applications such as electric vehicles and renewable energy systems. Planar gate structures, while simpler and cost-effective, face scaling challenges that limit their performance in sub-10 nm nodes, driving industry adoption of trench gate and FinFET architectures. Future trends emphasize integrating trench gates with novel materials like GaN and SiC to enhance thermal management and switching speeds in high-frequency, high-power semiconductor devices.

Trench gate vs Planar gate Infographic

electrown.com

electrown.com