C-V measurement focuses on determining the capacitance-voltage relationship of semiconductor devices, providing insights into doping profiles and interface states. Understanding the distinctions between C-V and I-V measurements can enhance your analysis of device characteristics--explore the rest of the article to learn more.

Table of Comparison

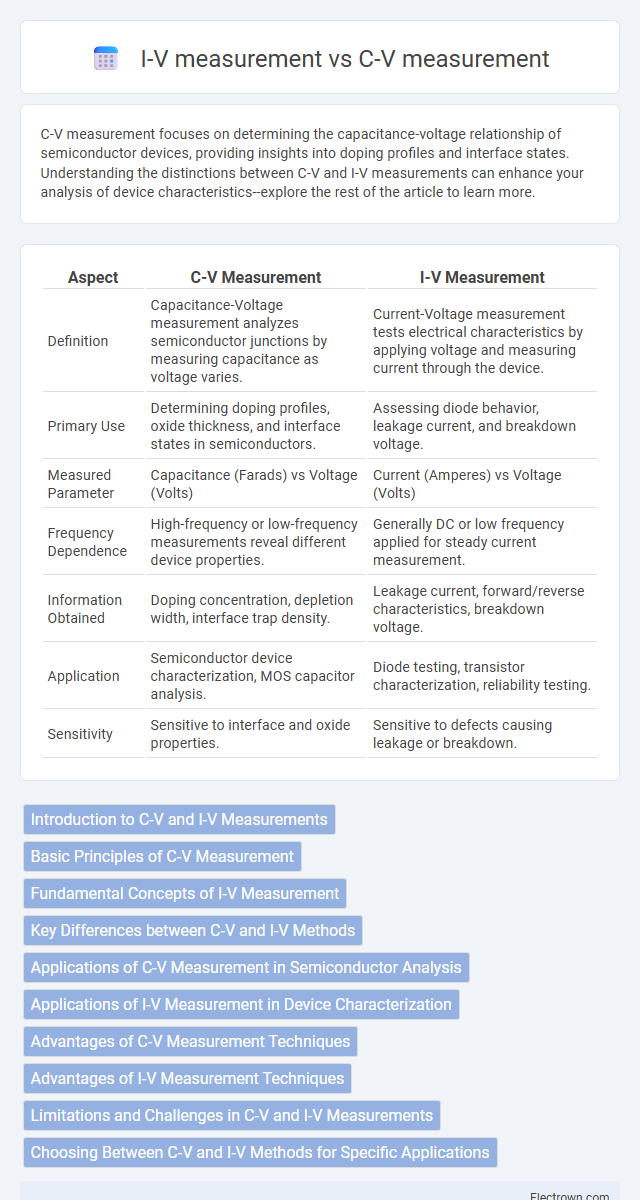

| Aspect | C-V Measurement | I-V Measurement |

|---|---|---|

| Definition | Capacitance-Voltage measurement analyzes semiconductor junctions by measuring capacitance as voltage varies. | Current-Voltage measurement tests electrical characteristics by applying voltage and measuring current through the device. |

| Primary Use | Determining doping profiles, oxide thickness, and interface states in semiconductors. | Assessing diode behavior, leakage current, and breakdown voltage. |

| Measured Parameter | Capacitance (Farads) vs Voltage (Volts) | Current (Amperes) vs Voltage (Volts) |

| Frequency Dependence | High-frequency or low-frequency measurements reveal different device properties. | Generally DC or low frequency applied for steady current measurement. |

| Information Obtained | Doping concentration, depletion width, interface trap density. | Leakage current, forward/reverse characteristics, breakdown voltage. |

| Application | Semiconductor device characterization, MOS capacitor analysis. | Diode testing, transistor characterization, reliability testing. |

| Sensitivity | Sensitive to interface and oxide properties. | Sensitive to defects causing leakage or breakdown. |

Introduction to C-V and I-V Measurements

C-V (Capacitance-Voltage) measurement characterizes the dielectric properties and interface quality of semiconductor materials by analyzing capacitance changes with applied voltage, providing insights into doping concentration and oxide thickness. I-V (Current-Voltage) measurement evaluates the electrical behavior of devices by recording current flow in response to voltage, essential for identifying leakage currents, breakdown voltages, and device performance. Both techniques are fundamental in semiconductor device analysis, with C-V measurements focusing on junction properties and I-V measurements emphasizing conduction mechanisms.

Basic Principles of C-V Measurement

C-V measurement analyzes the capacitance-voltage relationship of semiconductor devices, primarily assessing the doping profile and interface states by applying a varying voltage and measuring the resulting capacitance. This technique leverages the depletion region's width modulation under different bias conditions, providing insight into charge distribution and junction properties. Unlike I-V measurement, which focuses on current response, C-V profiling enables non-destructive evaluation of device parameters such as oxide thickness and trap density.

Fundamental Concepts of I-V Measurement

I-V measurement involves analyzing the current response of a device under varying voltage to characterize electrical properties such as resistance, conductivity, and diode behavior. It provides direct insight into charge transport mechanisms, threshold voltages, and leakage currents within semiconductors or electronic components. These measurements are crucial for assessing device performance, reliability, and identifying defects through parameters like current-voltage curves and breakdown voltages.

Key Differences between C-V and I-V Methods

C-V measurement analyzes the capacitance-voltage relationship to extract semiconductor properties such as doping concentration and depletion layer width, while I-V measurement evaluates current-voltage characteristics to assess device behavior like leakage current and breakdown voltage. The C-V method is non-destructive and sensitive to interface states and junction capacitance changes, whereas the I-V technique provides direct information on charge transport mechanisms and electrical conductivity. C-V profiling is commonly used for doping profile analysis, whereas I-V testing is essential for device reliability and performance evaluation.

Applications of C-V Measurement in Semiconductor Analysis

C-V measurement is essential for analyzing semiconductor properties such as doping concentration, oxide thickness, and interface trap density, offering detailed insights into material and device quality. This technique is widely used in characterizing MOS capacitors, thin films, and junctions, enabling precise control over manufacturing processes. Your ability to optimize semiconductor devices improves significantly through the accurate profiling provided by C-V measurements compared to basic I-V analysis, which primarily focuses on current flow and device behavior under bias.

Applications of I-V Measurement in Device Characterization

I-V measurement plays a crucial role in device characterization by providing detailed insights into electrical behavior such as current flow, resistance, and breakdown voltage of semiconductors and electronic components. This method is essential for identifying leakage currents, threshold voltages, and device reliability under varying bias conditions, enabling precise evaluation of diodes, transistors, and photovoltaic cells. Your ability to optimize device performance and ensure quality control heavily relies on accurate I-V analysis in research and manufacturing environments.

Advantages of C-V Measurement Techniques

C-V measurement techniques excel in characterizing semiconductor devices by providing detailed information about doping profiles, oxide thickness, and interface trap densities, which I-V measurements cannot directly reveal. These techniques offer high sensitivity to electrical properties and enable the precise extraction of capacitance-voltage relationships critical for device optimization and reliability testing. Your analysis benefits from enhanced accuracy in identifying material and device parameters essential for improving performance and fabrication processes.

Advantages of I-V Measurement Techniques

I-V measurement techniques provide direct insight into the electrical characteristics of semiconductor devices by quantifying current flow under varying voltage conditions, enabling precise detection of leakage currents, breakdown voltages, and resistive losses. These measurements are critical for assessing device performance, reliability, and failure mechanisms, offering rapid data collection and straightforward interpretation. Your ability to analyze diode junctions, transistor behavior, and material properties is significantly enhanced by the high sensitivity and accuracy of I-V measurements compared to C-V methods.

Limitations and Challenges in C-V and I-V Measurements

C-V measurements face limitations such as sensitivity to interface traps, frequency dispersion, and the requirement for precise calibration to avoid inaccurate capacitance values. I-V measurements encounter challenges including contact resistance effects, leakage currents, and non-idealities like hysteresis, which complicate accurate extraction of device parameters. Your analysis should consider these inherent difficulties to ensure reliable characterization of semiconductor devices.

Choosing Between C-V and I-V Methods for Specific Applications

C-V (Capacitance-Voltage) measurements provide critical insights into semiconductor junction properties, such as doping profiles and interface states, making them ideal for analyzing MOS capacitors and diode junctions. I-V (Current-Voltage) measurements focus on electrical behavior under varying voltage, essential for characterizing device leakage, breakdown voltage, and diode conduction efficiency. Your choice depends on whether detailed information about material properties (C-V) or device performance under bias (I-V) is more relevant to your specific semiconductor analysis needs.

C-V measurement vs I-V measurement Infographic

electrown.com

electrown.com