Ball-grid array (BGA) packages offer superior electrical performance and thermal conductivity compared to quad flat packages (QFP) due to their shorter interconnects and efficient heat dissipation. Explore the rest of the article to understand which package best suits Your electronic design needs.

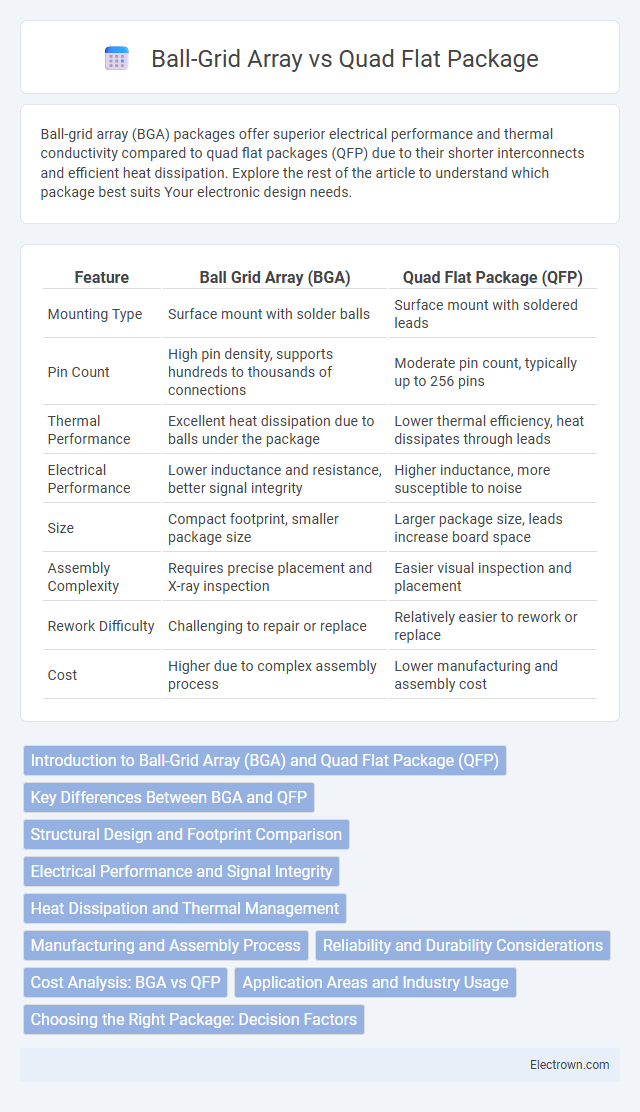

Table of Comparison

| Feature | Ball Grid Array (BGA) | Quad Flat Package (QFP) |

|---|---|---|

| Mounting Type | Surface mount with solder balls | Surface mount with soldered leads |

| Pin Count | High pin density, supports hundreds to thousands of connections | Moderate pin count, typically up to 256 pins |

| Thermal Performance | Excellent heat dissipation due to balls under the package | Lower thermal efficiency, heat dissipates through leads |

| Electrical Performance | Lower inductance and resistance, better signal integrity | Higher inductance, more susceptible to noise |

| Size | Compact footprint, smaller package size | Larger package size, leads increase board space |

| Assembly Complexity | Requires precise placement and X-ray inspection | Easier visual inspection and placement |

| Rework Difficulty | Challenging to repair or replace | Relatively easier to rework or replace |

| Cost | Higher due to complex assembly process | Lower manufacturing and assembly cost |

Introduction to Ball-Grid Array (BGA) and Quad Flat Package (QFP)

Ball-Grid Array (BGA) packages feature an array of solder balls on the underside of the component, providing superior thermal performance and electrical connections compared to traditional packages. Quad Flat Package (QFP) consists of a rectangular or square flat plastic housing with leads extending from all four sides, allowing for easy surface mounting on PCBs. BGA is typically favored for high-density, high-performance applications, while QFP is widely used in moderate pin count and cost-sensitive designs.

Key Differences Between BGA and QFP

Ball-grid array (BGA) packages feature an array of solder balls on the underside for electrical connections, providing superior thermal and electrical performance compared to quad flat packages (QFP), which use flat, gull-wing leads extending from all four sides. BGA offers higher pin density and better heat dissipation, making it ideal for complex, high-performance integrated circuits, while QFP is easier to inspect and rework, often preferred for prototypes and lower pin counts. The mechanical robustness and reduced inductance of BGA improve signal integrity, contrasting with the relatively higher inductance and fragility of QFP leads.

Structural Design and Footprint Comparison

Ball-grid array (BGA) packages feature solder balls arranged in a grid on the underside, enabling a smaller footprint and improved thermal performance compared to quad flat packages (QFP), which have gull-wing leads extending from each side. The structural design of BGAs allows for higher pin density and reduced lead inductance, optimizing signal integrity and assembly reliability. QFPs offer easier visual inspection and rework due to their exposed leads but require larger board space and can be more susceptible to mechanical stress.

Electrical Performance and Signal Integrity

Ball-grid array (BGA) packages offer superior electrical performance and signal integrity compared to quad flat packages (QFP) due to shorter interconnect paths and reduced parasitic inductance and capacitance, minimizing signal degradation. BGAs provide improved grounding and power distribution, which enhances high-frequency performance and reduces electromagnetic interference (EMI). The enhanced thermal management in BGAs also contributes to maintaining stable electrical characteristics under varying operational conditions.

Heat Dissipation and Thermal Management

Ball-grid array (BGA) packages offer superior heat dissipation compared to quad flat packages (QFP) due to their ability to make direct contact between the die and the PCB through solder balls, which enhances thermal conductivity. Thermal management in BGAs is more efficient as the distributed solder balls allow heat to spread evenly and reduce hotspots, benefiting high-power applications. Your system's reliability improves with BGA devices when efficient heat removal is essential for maintaining optimal performance and preventing thermal-induced failures.

Manufacturing and Assembly Process

The Ball Grid Array (BGA) package offers a streamlined manufacturing process through its grid of solder balls, enabling automated placement and reflow soldering with high precision and reduced lead inductance. In contrast, the Quad Flat Package (QFP) involves intricate lead alignment and manual or semi-automated soldering, increasing the risk of solder bridging and assembly defects. BGA's superior thermal and electrical performance results from its efficient heat dissipation and strong mechanical connections formed during the reflow process.

Reliability and Durability Considerations

Ball-grid array (BGA) packages offer superior reliability and durability compared to quad flat packages (QFP) due to their enhanced thermal performance and robust solder joint design. The solder balls in BGA provide better resistance to mechanical stress and thermal cycling, reducing the risk of joint fatigue and failure. In contrast, QFPs are more susceptible to lead bending and solder joint cracking under mechanical or thermal stress, impacting long-term durability.

Cost Analysis: BGA vs QFP

Ball-grid array (BGA) packages typically have higher initial manufacturing costs compared to quad flat packages (QFP) due to more complex assembly processes and specialized equipment requirements. However, BGA offers better thermal performance and electrical characteristics, potentially reducing long-term operational costs and improving reliability. Your choice between BGA and QFP should consider both upfront expenses and total cost of ownership based on application demands.

Application Areas and Industry Usage

Ball-grid array (BGA) packages excel in high-performance computing, telecommunications, and mobile devices due to their superior thermal management and electrical performance, supporting applications like processors and memory modules. Quad flat packages (QFP) are widely used in consumer electronics, automotive control systems, and industrial automation, favored for their ease of inspection and soldering in moderate pin count applications. The semiconductor industry leverages BGA for miniaturized, high-speed circuits, while QFP remains prominent in cost-sensitive, lower I/O environments.

Choosing the Right Package: Decision Factors

Choosing the right package between Ball Grid Array (BGA) and Quad Flat Package (QFP) depends on factors like PCB space, thermal performance, and signal integrity requirements. BGA offers superior electrical performance and heat dissipation due to its array of solder balls, making it suitable for high-density and high-frequency applications. QFP is preferred for easy visual inspection and simpler rework in lower pin count devices where PCB space is less constrained.

Ball-grid array vs quad flat package Infographic

electrown.com

electrown.com