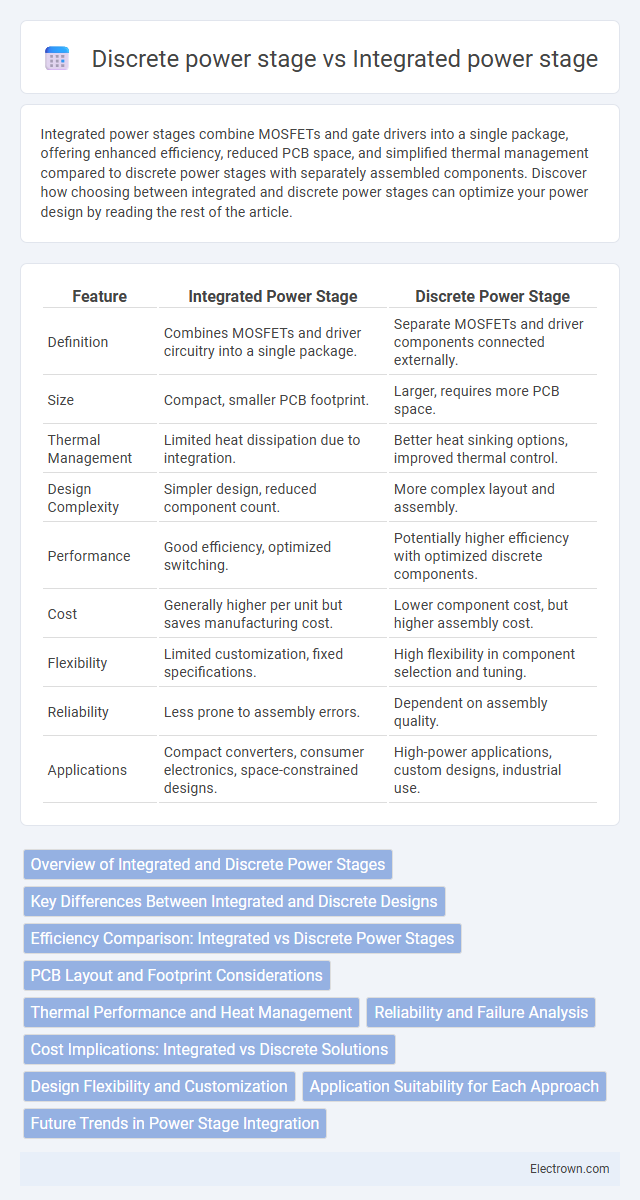

Integrated power stages combine MOSFETs and gate drivers into a single package, offering enhanced efficiency, reduced PCB space, and simplified thermal management compared to discrete power stages with separately assembled components. Discover how choosing between integrated and discrete power stages can optimize your power design by reading the rest of the article.

Table of Comparison

| Feature | Integrated Power Stage | Discrete Power Stage |

|---|---|---|

| Definition | Combines MOSFETs and driver circuitry into a single package. | Separate MOSFETs and driver components connected externally. |

| Size | Compact, smaller PCB footprint. | Larger, requires more PCB space. |

| Thermal Management | Limited heat dissipation due to integration. | Better heat sinking options, improved thermal control. |

| Design Complexity | Simpler design, reduced component count. | More complex layout and assembly. |

| Performance | Good efficiency, optimized switching. | Potentially higher efficiency with optimized discrete components. |

| Cost | Generally higher per unit but saves manufacturing cost. | Lower component cost, but higher assembly cost. |

| Flexibility | Limited customization, fixed specifications. | High flexibility in component selection and tuning. |

| Reliability | Less prone to assembly errors. | Dependent on assembly quality. |

| Applications | Compact converters, consumer electronics, space-constrained designs. | High-power applications, custom designs, industrial use. |

Overview of Integrated and Discrete Power Stages

Integrated power stages combine power MOSFETs and gate drivers into a single compact module, optimizing thermal performance and reducing parasitic inductance for higher efficiency and simplified PCB layout. Discrete power stages separate MOSFETs and drivers, offering greater design flexibility and customization at the cost of increased layout complexity and potentially higher electromagnetic interference. Selection between integrated and discrete power stages depends on application requirements such as power density, efficiency targets, and design constraints.

Key Differences Between Integrated and Discrete Designs

Integrated power stages combine the MOSFETs and gate drivers into a single package, reducing circuit complexity, improving switching performance, and enhancing thermal management compared to discrete power stages, which use separate components. Discrete power stages offer greater design flexibility and customization for specific applications but may result in larger PCB footprints and increased parasitic inductance. Your choice impacts efficiency, reliability, and assembly time, with integrated solutions favoring compact design and discrete designs enabling tailored performance.

Efficiency Comparison: Integrated vs Discrete Power Stages

Integrated power stages offer improved efficiency by reducing parasitic inductances and minimizing power losses through closely coupled components on a single substrate. Discrete power stages, while providing design flexibility, often suffer from higher conduction and switching losses due to longer interconnections and separate packaging. Choosing an integrated power stage can enhance your system's overall energy efficiency and thermal performance compared to a discrete solution.

PCB Layout and Footprint Considerations

Integrated power stages offer a more compact PCB layout with reduced footprint compared to discrete power stages, enabling higher component density and simplified routing. Discrete power stages, while larger and more complex, provide greater flexibility in component selection and placement, which may be necessary for custom thermal or electrical requirements. When optimizing your design, integrated solutions minimize parasitic inductance and improve efficiency, but discrete layouts allow tailored optimization of the power stage footprint.

Thermal Performance and Heat Management

Integrated power stages typically offer superior thermal performance due to their compact design and closely coupled components, which enable more efficient heat dissipation through a unified substrate. Discrete power stages, while often providing higher flexibility, can suffer from increased thermal resistance caused by multiple interfaces and separate packaging, complicating heat management. Optimizing heat sinks and PCB layout is crucial for discrete stages to achieve reliable thermal control comparable to integrated solutions.

Reliability and Failure Analysis

Integrated power stages offer enhanced reliability through reduced component count and optimized thermal management, minimizing failure points commonly associated with discrete power stages. Failure analysis indicates that discrete power stages are more prone to solder joint failures and component mismatches due to their separate assembly, which can lead to uneven thermal stress. The unified design of integrated power stages allows for more consistent performance and easier identification of failure modes, improving overall system robustness.

Cost Implications: Integrated vs Discrete Solutions

Integrated power stages generally offer lower overall cost due to reduced component count and simplified PCB design, which minimizes assembly time and manufacturing expenses. Discrete power stages, while potentially providing higher customization and performance optimization, incur higher costs from increased material usage and complex assembly processes. For cost-sensitive applications, integrated solutions deliver better economic efficiency, whereas discrete designs may justify their expense in high-performance or specialized contexts.

Design Flexibility and Customization

Discrete power stages offer greater design flexibility and customization by allowing engineers to select individual components tailored to specific voltage, current, and thermal requirements, optimizing performance for unique applications. Integrated power stages combine MOSFETs and drivers into a single package, simplifying design and reducing board space but limiting the ability to fine-tune parameters or replace components independently. Your choice depends on whether precise customization or compact, streamlined design is a higher priority for your power management needs.

Application Suitability for Each Approach

Integrated power stages offer compact design and simplified thermal management, making them ideal for applications requiring space efficiency and high switching frequencies, such as consumer electronics and portable devices. Discrete power stages provide greater flexibility and customization, suitable for high-power industrial equipment and systems demanding precise performance tuning and enhanced thermal dissipation. Your choice depends on whether you prioritize integration for compactness or customization for robust, high-power applications.

Future Trends in Power Stage Integration

Future trends in power stage integration emphasize higher efficiency and compact design through advanced semiconductor materials like GaN and SiC, enabling faster switching speeds and reduced thermal losses. Increasing demand for electric vehicles and renewable energy systems drives the development of more integrated solutions combining power transistors and gate drivers on a single chip to enhance reliability and reduce manufacturing costs. The shift towards smart power stages with embedded sensors and digital control interfaces facilitates real-time monitoring and predictive maintenance, optimizing system performance and longevity.

Integrated power stage vs Discrete power stage Infographic

electrown.com

electrown.com