Surface mount technology (SMT) offers compact, high-density circuit designs with faster assembly and better performance in high-frequency applications, while through-hole technology provides stronger mechanical bonds ideal for components subjected to mechanical stress. Understanding the advantages and applications of both methods will help you choose the most suitable approach for your electronics project--read on to explore detailed comparisons and expert insights.

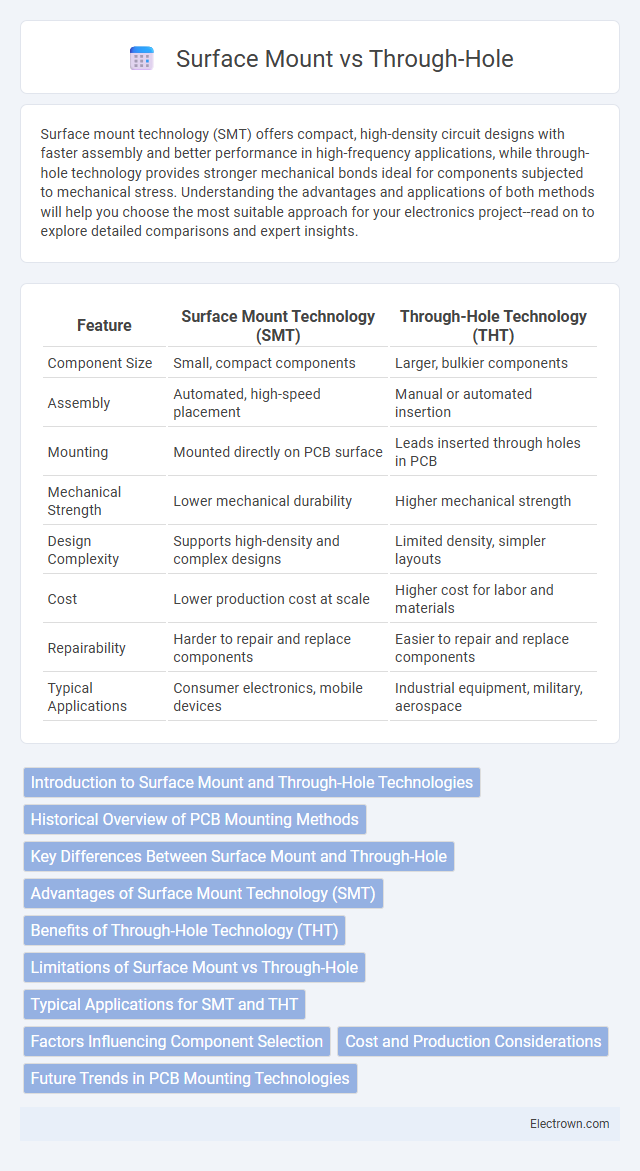

Table of Comparison

| Feature | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

|---|---|---|

| Component Size | Small, compact components | Larger, bulkier components |

| Assembly | Automated, high-speed placement | Manual or automated insertion |

| Mounting | Mounted directly on PCB surface | Leads inserted through holes in PCB |

| Mechanical Strength | Lower mechanical durability | Higher mechanical strength |

| Design Complexity | Supports high-density and complex designs | Limited density, simpler layouts |

| Cost | Lower production cost at scale | Higher cost for labor and materials |

| Repairability | Harder to repair and replace components | Easier to repair and replace components |

| Typical Applications | Consumer electronics, mobile devices | Industrial equipment, military, aerospace |

Introduction to Surface Mount and Through-Hole Technologies

Surface mount technology (SMT) involves directly placing components onto the surface of printed circuit boards (PCBs), enabling smaller, lighter designs with higher component density. Through-hole technology (THT) requires inserting component leads into pre-drilled holes on the PCB, offering robust mechanical connections ideal for high-stress applications. Understanding these methods helps you choose the best assembly process based on project requirements and manufacturing efficiency.

Historical Overview of PCB Mounting Methods

Surface mount technology (SMT) emerged in the 1960s as a response to the demand for miniaturization and higher circuit density, gradually replacing the earlier through-hole technology that dominated PCB assembly since the 1950s. Through-hole mounting involves inserting component leads directly into drilled holes on the PCB, providing mechanical strength and reliability critical in early electronics like military and aerospace applications. The shift to SMT allowed for automated assembly processes, reduced manufacturing costs, and enabled compact, high-performance devices in consumer electronics throughout the late 20th century.

Key Differences Between Surface Mount and Through-Hole

Surface mount technology (SMT) uses smaller, flat components directly placed on the PCB surface, enabling higher circuit density and automated assembly, while through-hole technology involves inserting component leads into drilled holes, providing stronger mechanical bonds ideal for heavy or high-stress parts. SMT typically allows for faster production and reduced material costs due to miniaturization, whereas through-hole offers better durability and easier manual prototyping or repair. Understanding these distinctions helps you choose the best method based on your project's requirements for size, strength, and manufacturing complexity.

Advantages of Surface Mount Technology (SMT)

Surface Mount Technology (SMT) offers significant advantages such as smaller component size enabling higher circuit density and more compact designs. SMT improves manufacturing efficiency with faster assembly and automated processes, reducing labor costs and minimizing errors. Your electronic devices benefit from enhanced performance and reliability due to reduced lead inductance and better thermal management.

Benefits of Through-Hole Technology (THT)

Through-Hole Technology (THT) offers superior mechanical strength and reliability, making it ideal for components subjected to high stress or mechanical strain. THT ensures strong, durable electrical connections by inserting component leads through drilled holes and soldering them on the opposite side of the PCB. This method enhances thermal performance and allows for easier manual assembly and repair in prototypes or low-volume production.

Limitations of Surface Mount vs Through-Hole

Surface mount technology (SMT) faces limitations such as lower mechanical strength and difficulty in handling high-power components compared to through-hole mounting, which offers superior durability and heat dissipation. Through-hole components are better suited for heavy-duty applications but require more space and complex assembly processes. Your choice depends on balancing the need for compact design against reliability and ease of repair.

Typical Applications for SMT and THT

Surface mount technology (SMT) is predominantly used in high-density electronic devices such as smartphones, laptops, and wearable gadgets due to its compact size and automated assembly benefits. Through-hole technology (THT) is favored in applications requiring strong mechanical bonds and reliability, including aerospace, military, and automotive electronics where durability and ease of inspection are critical. SMT suits mass production of complex circuits with miniaturized components, while THT remains ideal for prototyping, connectors, and components subject to high mechanical stress.

Factors Influencing Component Selection

Component selection between surface mount and through-hole technology depends on factors such as board space constraints, mechanical strength requirements, and manufacturing volume. Surface mount devices (SMDs) offer compact size and high-density placement ideal for automated assembly, while through-hole components provide superior mechanical stability suited for connectors or high-stress applications. Your choice should consider cost, assembly technique, thermal performance, and repairability to ensure optimal functionality and reliability in the final electronic product.

Cost and Production Considerations

Surface mount technology (SMT) typically reduces production costs due to smaller component size, automated placement, and higher assembly speeds. Through-hole technology involves higher labor costs and longer production times, but provides stronger mechanical connections for heavy or high-stress components. Choosing the right method depends on your budget, production volume, and the mechanical requirements of the final product.

Future Trends in PCB Mounting Technologies

Future trends in PCB mounting technologies emphasize miniaturization and increased automation, driving the adoption of advanced surface mount technology (SMT) over traditional through-hole methods. Innovations such as 3D printing for printed circuit boards and embedded components enhance design flexibility and electrical performance, while automated optical inspection (AOI) systems improve assembly precision and yield rates. Your electronic designs will benefit from these emerging technologies by enabling higher component density and improved reliability in compact devices.

Surface mount vs through-hole Infographic

electrown.com

electrown.com