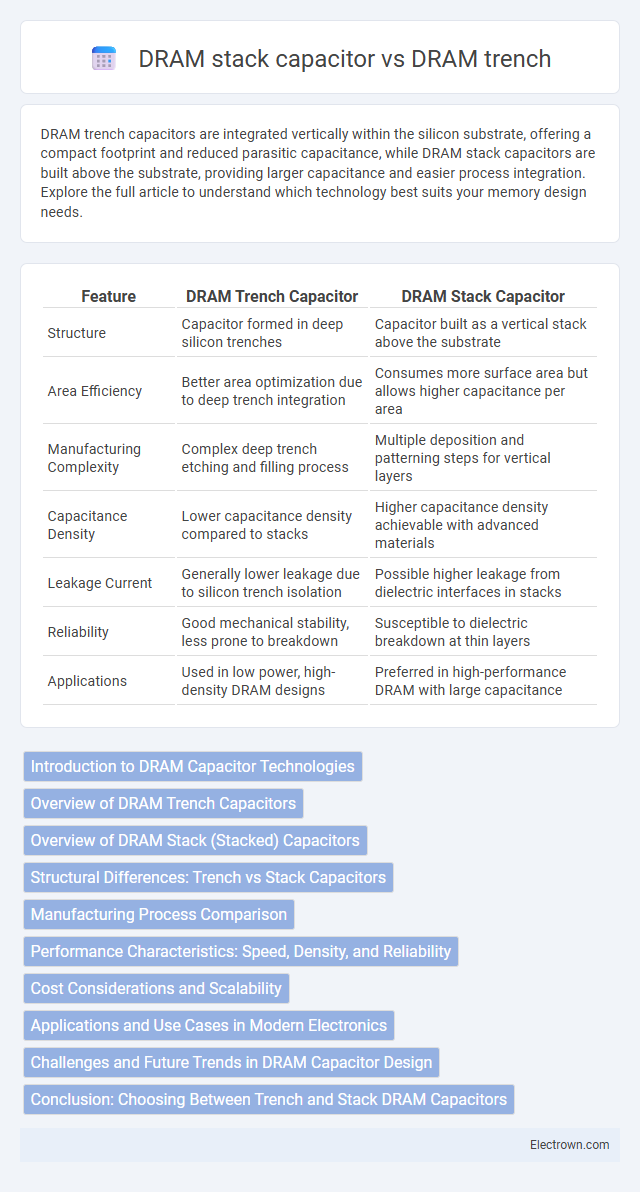

DRAM trench capacitors are integrated vertically within the silicon substrate, offering a compact footprint and reduced parasitic capacitance, while DRAM stack capacitors are built above the substrate, providing larger capacitance and easier process integration. Explore the full article to understand which technology best suits your memory design needs.

Table of Comparison

| Feature | DRAM Trench Capacitor | DRAM Stack Capacitor |

|---|---|---|

| Structure | Capacitor formed in deep silicon trenches | Capacitor built as a vertical stack above the substrate |

| Area Efficiency | Better area optimization due to deep trench integration | Consumes more surface area but allows higher capacitance per area |

| Manufacturing Complexity | Complex deep trench etching and filling process | Multiple deposition and patterning steps for vertical layers |

| Capacitance Density | Lower capacitance density compared to stacks | Higher capacitance density achievable with advanced materials |

| Leakage Current | Generally lower leakage due to silicon trench isolation | Possible higher leakage from dielectric interfaces in stacks |

| Reliability | Good mechanical stability, less prone to breakdown | Susceptible to dielectric breakdown at thin layers |

| Applications | Used in low power, high-density DRAM designs | Preferred in high-performance DRAM with large capacitance |

Introduction to DRAM Capacitor Technologies

DRAM capacitor technologies primarily include trench capacitors and stacked capacitors, each designed to optimize charge storage within limited chip area. Trench capacitors integrate deep vertical structures etched into the silicon substrate, offering high capacitance density by utilizing the substrate depth. Stacked capacitors, conversely, build multiple capacitor layers above the substrate surface, enabling greater scalability and easier integration with standard CMOS processes for advanced memory nodes.

Overview of DRAM Trench Capacitors

DRAM trench capacitors use deep, narrow trenches etched into the silicon substrate to maximize the surface area for charge storage, delivering higher capacitance within a smaller footprint compared to planar capacitors. These capacitors improve density and scalability, making them suitable for high-performance memory applications where space is limited. Your device benefits from enhanced storage capacity and reliability due to the optimized electric field distribution in trench designs.

Overview of DRAM Stack (Stacked) Capacitors

DRAM stack capacitors utilize a multi-layer structure to increase capacitance within a limited chip area, enhancing memory density and performance. Their vertical stacking design enables higher charge storage and improved scalability compared to trench capacitors, which form capacitors by etching deep trenches into the silicon substrate. Stack capacitors dominate in modern DRAM technology due to better process compatibility and reduced manufacturing complexity.

Structural Differences: Trench vs Stack Capacitors

DRAM trench capacitors are embedded vertically into the silicon substrate, creating a deep, cylindrical structure that maximizes surface area within a small footprint. In contrast, DRAM stack capacitors are constructed above the substrate, layering multiple conductive and dielectric materials to form a three-dimensional stack that increases capacitance. Your choice between trench and stack capacitor designs impacts chip density, manufacturing complexity, and electrical performance, making structural differences a key factor in DRAM optimization.

Manufacturing Process Comparison

DRAM trench capacitors are fabricated by etching deep, narrow trenches into the silicon substrate, allowing higher capacitance density within a smaller footprint, but the complex etching and filling processes increase manufacturing difficulty and cost. DRAM stack capacitors are built by depositing multiple layers of dielectric and electrode materials above the silicon surface, offering simpler planar processing and better compatibility with standard CMOS technology, though they often require more chip area. The trade-off between process complexity and capacitor geometry influences yield, scaling potential, and overall device performance in dynamic random-access memory fabrication.

Performance Characteristics: Speed, Density, and Reliability

DRAM trench capacitors offer higher density by utilizing vertical silicon trenches, enabling compact cell sizes and improved scalability for memory arrays. Stack capacitors, while generally larger, provide better reliability and potentially faster access speeds due to simpler fabrication and reduced leakage current. Speed performance in trench capacitors can be affected by increased parasitic capacitance, whereas stack capacitors maintain consistent speed and durability across various process nodes.

Cost Considerations and Scalability

DRAM trench capacitors offer lower manufacturing costs due to simpler planar processes but face scalability challenges as feature sizes shrink, limiting their effectiveness in advanced nodes. Stack capacitors provide superior scalability for high-density DRAM designs by enabling vertical integration, though this comes with increased fabrication complexity and higher production expenses. Your choice depends on balancing initial cost efficiency against long-term scalability requirements for future memory technology nodes.

Applications and Use Cases in Modern Electronics

DRAM trench capacitors are predominantly used in embedded DRAM applications where space efficiency and integration with logic circuits are critical, such as in mobile devices and low-power embedded systems. DRAM stack capacitors find extensive use in high-density memory modules like desktop and server DRAM due to their superior scalability and higher capacitance per cell. Both capacitor types are essential in modern electronics, optimizing performance and power consumption based on specific device requirements.

Challenges and Future Trends in DRAM Capacitor Design

DRAM trench capacitors face challenges such as limited scalability and increased manufacturing complexity, while DRAM stack capacitors struggle with maintaining high capacitance in reduced form factors. Future trends in DRAM capacitor design focus on novel materials and 3D architectures to enhance capacitance density and reduce leakage currents. Your ability to leverage these advancements will be crucial for developing next-generation memory solutions with improved performance and energy efficiency.

Conclusion: Choosing Between Trench and Stack DRAM Capacitors

Trench DRAM capacitors offer improved scaling and reduced cell area by embedding the capacitor vertically into the silicon substrate, making them suitable for advanced nodes requiring high density. Stack DRAM capacitors provide better capacitance stability and simpler fabrication processes, which can result in lower manufacturing costs and enhanced reliability at slightly larger cell sizes. Selecting between trench and stack capacitors depends on prioritizing either device scaling and cell density (favoring trench) or process simplicity and capacitance uniformity (favoring stack).

DRAM trench vs DRAM stack capacitor Infographic

electrown.com

electrown.com