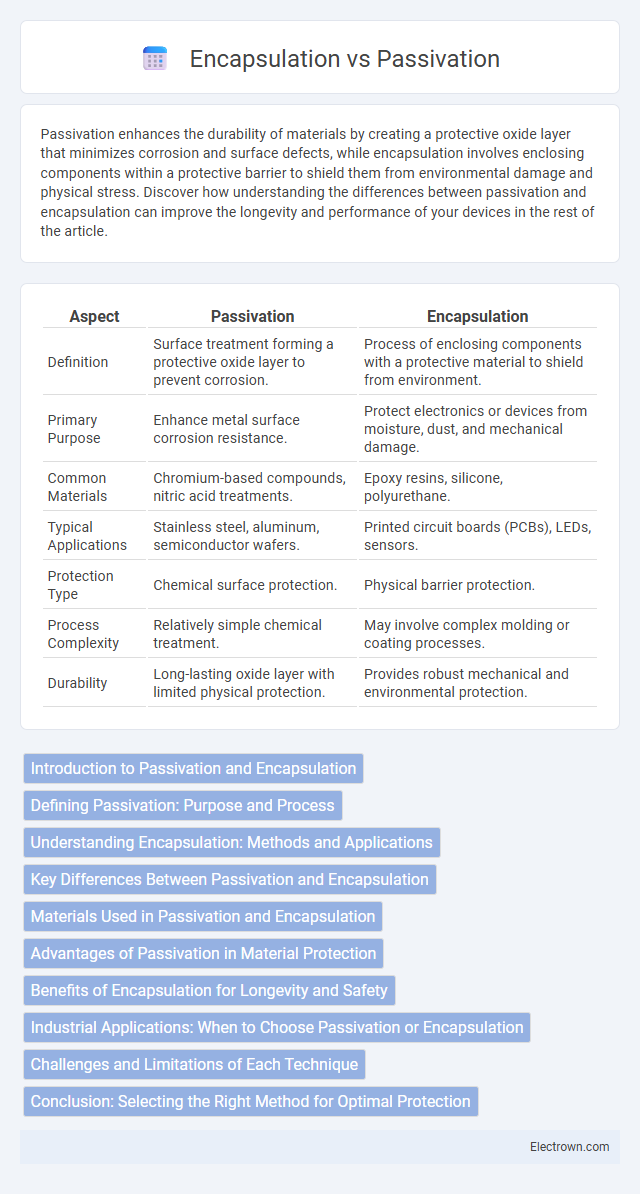

Passivation enhances the durability of materials by creating a protective oxide layer that minimizes corrosion and surface defects, while encapsulation involves enclosing components within a protective barrier to shield them from environmental damage and physical stress. Discover how understanding the differences between passivation and encapsulation can improve the longevity and performance of your devices in the rest of the article.

Table of Comparison

| Aspect | Passivation | Encapsulation |

|---|---|---|

| Definition | Surface treatment forming a protective oxide layer to prevent corrosion. | Process of enclosing components with a protective material to shield from environment. |

| Primary Purpose | Enhance metal surface corrosion resistance. | Protect electronics or devices from moisture, dust, and mechanical damage. |

| Common Materials | Chromium-based compounds, nitric acid treatments. | Epoxy resins, silicone, polyurethane. |

| Typical Applications | Stainless steel, aluminum, semiconductor wafers. | Printed circuit boards (PCBs), LEDs, sensors. |

| Protection Type | Chemical surface protection. | Physical barrier protection. |

| Process Complexity | Relatively simple chemical treatment. | May involve complex molding or coating processes. |

| Durability | Long-lasting oxide layer with limited physical protection. | Provides robust mechanical and environmental protection. |

Introduction to Passivation and Encapsulation

Passivation involves creating a protective oxide layer on a metal surface to prevent corrosion and enhance durability, commonly used in semiconductor and automotive industries. Encapsulation refers to enclosing electronic components or materials in a protective barrier, such as polymer or resin, to shield against moisture, dust, and mechanical damage. Understanding the differences between passivation and encapsulation helps you choose the right method for protecting sensitive devices and improving their longevity.

Defining Passivation: Purpose and Process

Passivation is a chemical treatment process that enhances the corrosion resistance of metal surfaces by creating a thin, protective oxide layer. This controlled oxidation prevents contaminants from reaching the underlying metal, significantly improving durability and performance in harsh environments. Your equipment benefits from passivation by maintaining structural integrity and extending its operational lifespan without the need for additional coatings.

Understanding Encapsulation: Methods and Applications

Encapsulation involves coating or embedding materials to protect components from environmental damage, contamination, and corrosion, using methods such as polymer coatings, metal oxides, and thin-film deposition. Common applications include electronics, where encapsulation shields semiconductors from moisture and mechanical stress, and in solar cells, where it enhances durability and efficiency. Advanced encapsulation techniques improve device reliability and extend operational lifespans by providing robust barriers against physical, chemical, and thermal degradation.

Key Differences Between Passivation and Encapsulation

Passivation creates a protective oxide layer on the surface of metals to prevent corrosion, while encapsulation involves enclosing an object in a material to shield it from environmental damage. Passivation is typically a chemical process targeting metal surfaces, whereas encapsulation uses physical barriers such as polymers or resins. Understanding these key differences helps you select the appropriate technique for enhancing the durability and reliability of electronic components or metal parts.

Materials Used in Passivation and Encapsulation

Passivation typically employs materials like silicon nitride (Si3N4), silicon dioxide (SiO2), and aluminum oxide (Al2O3) to create a chemically stable, protective oxide layer on metal surfaces, reducing corrosion and enhancing durability. Encapsulation uses polymers such as epoxy resins, silicone, and polyurethane to fully enclose electronic components or devices, providing mechanical protection, moisture resistance, and electrical insulation. The selection of passivation materials targets minimizing surface reactivity, while encapsulation materials focus on environmental isolation and structural support.

Advantages of Passivation in Material Protection

Passivation enhances material protection by creating a thin, inert oxide layer that significantly reduces surface reactivity and corrosion. This self-healing barrier improves durability and extends the lifespan of metals, especially stainless steel and aluminum alloys, in harsh environments. Your equipment benefits from reduced maintenance costs and improved reliability due to passivation's robust defense against oxidation and chemical degradation.

Benefits of Encapsulation for Longevity and Safety

Encapsulation provides superior protection for electronic components by creating a physical barrier against moisture, dust, and chemical contaminants, significantly extending device longevity. This method enhances safety by preventing direct contact with hazardous materials and reducing the risk of electrical shorts. Your devices benefit from improved reliability and durability, making encapsulation a critical choice for long-term applications.

Industrial Applications: When to Choose Passivation or Encapsulation

Passivation is preferred in industrial applications requiring corrosion resistance and enhanced metal surface stability, often used in stainless steel components for aerospace and automotive industries. Encapsulation is chosen when environmental sealing and electrical insulation are critical, such as in semiconductor devices, sensors, and electronics manufacturing. The decision depends on whether surface protection or environmental isolation is the primary concern for the specific industrial process.

Challenges and Limitations of Each Technique

Passivation faces challenges in forming uniform, defect-free layers on diverse materials, often leading to incomplete protection against corrosion and surface contamination. Encapsulation can introduce limitations such as increased material thickness, added weight, and potential thermal management issues, which may impact device performance and miniaturization. Both techniques require careful material selection and process optimization to overcome issues like adhesion failures, mechanical stress, and long-term environmental durability.

Conclusion: Selecting the Right Method for Optimal Protection

Passivation and encapsulation serve distinct roles in protecting materials from corrosion and environmental damage; passivation creates a thin inert oxide layer to enhance surface durability while encapsulation involves coating the entire object with a protective barrier. Your choice depends on factors such as the environment, material type, and desired longevity, with passivation ideal for metals exposed to moderate oxidation and encapsulation preferred for harsh or variable conditions. Evaluating these criteria ensures optimal protection tailored to your specific application needs.

Passivation vs encapsulation Infographic

electrown.com

electrown.com