Pseudomorphic HEMTs (pHEMTs) use a thin strained layer to achieve high electron mobility while maintaining lattice matching, resulting in superior performance for high-frequency applications. Understanding the differences between pHEMTs and metamorphic HEMTs is crucial for optimizing your device selection and design; explore the full article to learn more about their characteristics and applications.

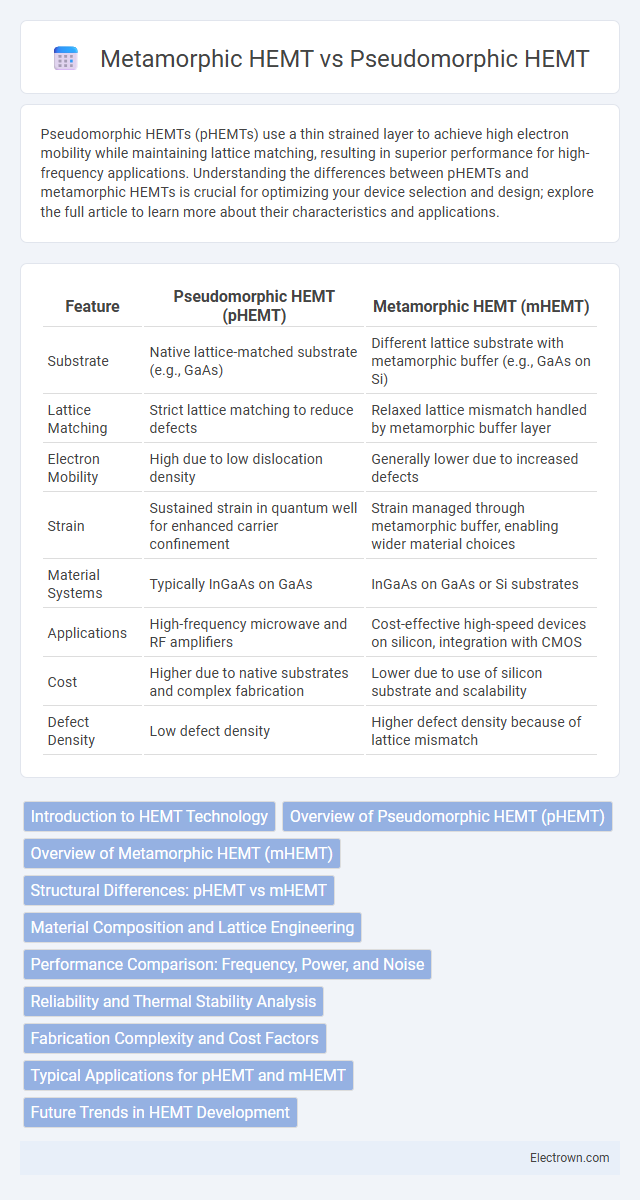

Table of Comparison

| Feature | Pseudomorphic HEMT (pHEMT) | Metamorphic HEMT (mHEMT) |

|---|---|---|

| Substrate | Native lattice-matched substrate (e.g., GaAs) | Different lattice substrate with metamorphic buffer (e.g., GaAs on Si) |

| Lattice Matching | Strict lattice matching to reduce defects | Relaxed lattice mismatch handled by metamorphic buffer layer |

| Electron Mobility | High due to low dislocation density | Generally lower due to increased defects |

| Strain | Sustained strain in quantum well for enhanced carrier confinement | Strain managed through metamorphic buffer, enabling wider material choices |

| Material Systems | Typically InGaAs on GaAs | InGaAs on GaAs or Si substrates |

| Applications | High-frequency microwave and RF amplifiers | Cost-effective high-speed devices on silicon, integration with CMOS |

| Cost | Higher due to native substrates and complex fabrication | Lower due to use of silicon substrate and scalability |

| Defect Density | Low defect density | Higher defect density because of lattice mismatch |

Introduction to HEMT Technology

High Electron Mobility Transistor (HEMT) technology leverages heterojunctions between different semiconductor materials to achieve superior electron mobility and faster switching speeds compared to traditional transistors. Pseudomorphic HEMTs (pHEMTs) utilize a thin, strained layer that maintains lattice matching to the substrate, enhancing electron transport and reducing defects. Metamorphic HEMTs (mHEMTs) introduce a relaxed buffer layer allowing lattice mismatch for integrating diverse materials, offering flexibility in material selection and improved high-frequency performance for your advanced electronic designs.

Overview of Pseudomorphic HEMT (pHEMT)

Pseudomorphic High Electron Mobility Transistors (pHEMTs) utilize a thin, strained semiconductor layer to achieve superior electron mobility and high-speed performance in RF and microwave applications. The pseudomorphic structure reduces lattice mismatch, enabling enhanced carrier confinement and lower noise figures compared to conventional HEMTs. Your choice of pHEMT devices can significantly improve signal integrity and power efficiency in advanced communication systems.

Overview of Metamorphic HEMT (mHEMT)

Metamorphic HEMTs (mHEMTs) utilize lattice-mismatched buffer layers to integrate high-electron-mobility channels on semiconductor substrates different from the channel material, enabling superior electron mobility and higher frequency performance compared to pseudomorphic HEMTs. By employing metamorphic buffer layers, mHEMTs achieve enhanced strain relaxation, allowing for larger bandgap differences and improved device scalability in microwave and millimeter-wave applications. Your choice of mHEMT can result in devices with higher cutoff frequencies and greater output power, making them ideal for RF amplifiers and high-speed transistors.

Structural Differences: pHEMT vs mHEMT

Pseudomorphic HEMTs (pHEMTs) feature a thin strained epitaxial layer grown lattice-matched to the substrate, preserving crystal integrity while enhancing electron mobility. Metamorphic HEMTs (mHEMTs) incorporate a relaxed buffer layer allowing lattice mismatch between the epitaxial layer and substrate, enabling the integration of high-indium-content channels for superior electron velocity. The structural distinction lies in pHEMT's reliance on pseudomorphic strain for improved performance versus mHEMT's use of metamorphic buffers to achieve broader material flexibility and higher electron saturation velocity.

Material Composition and Lattice Engineering

Pseudomorphic HEMTs utilize a thin epitaxial layer of InGaAs grown on a GaAs substrate, maintaining lattice coherence through careful lattice matching to reduce defects and improve electron mobility. Metamorphic HEMTs employ a graded buffer layer to accommodate lattice mismatch between the InGaAs channel and the GaAs or Si substrate, enabling higher indium content for enhanced electron velocity but introducing more dislocations. Advanced lattice engineering in pseudomorphic HEMTs focuses on strain and interface quality, while metamorphic designs prioritize buffer grading to manage strain relaxation and achieve high-performance transistor characteristics.

Performance Comparison: Frequency, Power, and Noise

Pseudomorphic HEMTs (pHEMTs) exhibit higher electron mobility due to lattice-matched channels, resulting in superior frequency performance and reduced noise figures compared to metamorphic HEMTs (mHEMTs). Metamorphic HEMTs enable higher power density by incorporating relaxed buffer layers for wider bandgap materials, allowing better thermal tolerance and power handling. While pHEMTs optimize low-noise amplification for applications like RF front-ends, mHEMTs excel in high-frequency power amplifiers where output power and robustness are critical.

Reliability and Thermal Stability Analysis

Pseudomorphic HEMTs (pHEMTs) exhibit enhanced reliability and superior thermal stability due to their lattice-matched interfaces, which minimize dislocation densities and reduce defect-related degradation under high-temperature operation. Metamorphic HEMTs (mHEMTs) offer greater flexibility in material selection and higher electron mobility but can experience increased defect generation and thermal stress from lattice mismatch, impacting long-term device stability. Thermal conductivity differences between the buffer layers in pHEMT and mHEMT structures critically influence heat dissipation efficiency, making pHEMTs generally more robust in thermal management for high-power applications.

Fabrication Complexity and Cost Factors

Pseudomorphic HEMTs (pHEMTs) utilize lattice-matched epitaxial layers, resulting in lower fabrication complexity and reduced defect density compared to metamorphic HEMTs (MHEMTs), which require complex buffer layers to accommodate lattice mismatch. The intricate buffer design in MHEMTs increases material and processing costs due to strain management and defect mitigation techniques. Your choice between pHEMT and MHEMT significantly impacts production expenses, where pHEMTs offer a cost-effective solution for applications demanding high electron mobility with simpler fabrication.

Typical Applications for pHEMT and mHEMT

Pseudomorphic HEMTs (pHEMTs) are commonly used in high-frequency applications such as wireless communication systems, satellite receivers, and radar due to their low noise and high electron mobility. Metamorphic HEMTs (mHEMTs) are preferred in higher power microwave and millimeter-wave applications, including 5G base stations and radar transmitters, because of their ability to operate at higher voltages and temperatures. Both devices enhance performance in RF front-end modules, but mHEMTs offer greater flexibility in lattice mismatch engineering for advanced power efficiency.

Future Trends in HEMT Development

Future trends in HEMT development emphasize enhancing electron mobility and thermal stability to meet the demands of high-frequency and high-power applications. Pseudomorphic HEMTs (pHEMTs) maintain lattice matching, ensuring superior device reliability and scalability for 5G and RF front-end modules. In contrast, metamorphic HEMTs (mHEMTs) enable the integration of higher indium content for increased electron velocity, driving advancements in millimeter-wave and next-generation wireless communication technologies.

Pseudomorphic HEMT vs metamorphic HEMT Infographic

electrown.com

electrown.com