Edge termination and field plate are two crucial techniques used in semiconductor device design to manage electric field distribution and enhance performance. Understanding the differences and benefits of each method can significantly improve your device reliability and efficiency; explore the rest of the article to learn how these technologies optimize your semiconductor applications.

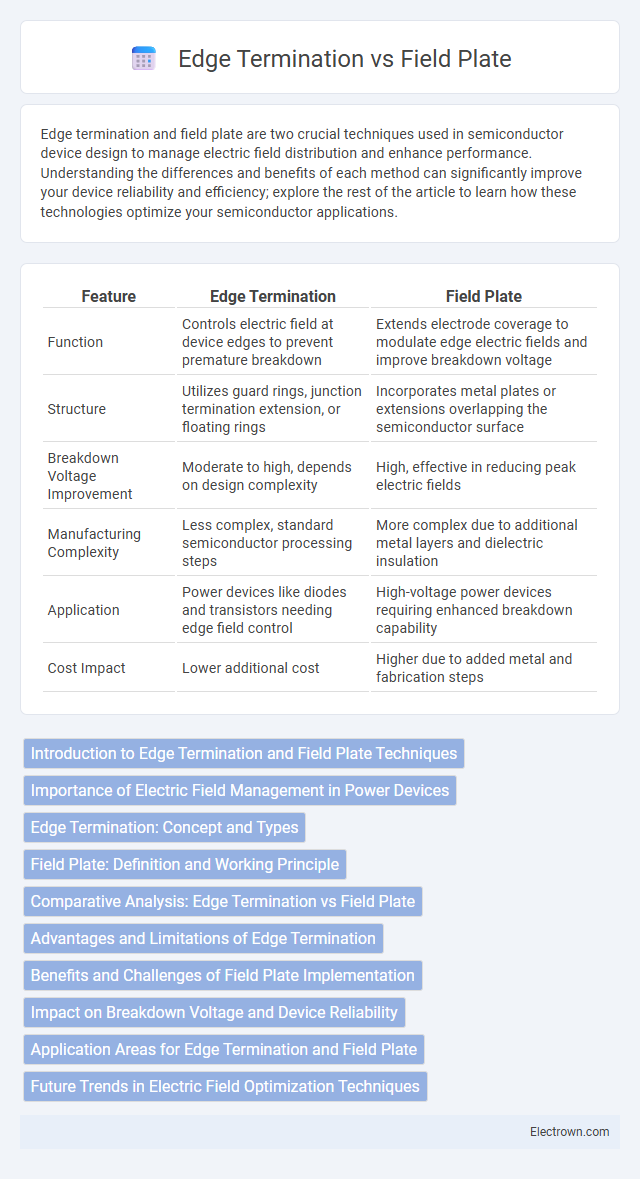

Table of Comparison

| Feature | Edge Termination | Field Plate |

|---|---|---|

| Function | Controls electric field at device edges to prevent premature breakdown | Extends electrode coverage to modulate edge electric fields and improve breakdown voltage |

| Structure | Utilizes guard rings, junction termination extension, or floating rings | Incorporates metal plates or extensions overlapping the semiconductor surface |

| Breakdown Voltage Improvement | Moderate to high, depends on design complexity | High, effective in reducing peak electric fields |

| Manufacturing Complexity | Less complex, standard semiconductor processing steps | More complex due to additional metal layers and dielectric insulation |

| Application | Power devices like diodes and transistors needing edge field control | High-voltage power devices requiring enhanced breakdown capability |

| Cost Impact | Lower additional cost | Higher due to added metal and fabrication steps |

Introduction to Edge Termination and Field Plate Techniques

Edge termination techniques enhance the reliability and breakdown voltage of power semiconductor devices by controlling the electric field at the device periphery. Field plates, a specialized type of edge termination, utilize metal layers extending over the passivation to modulate the surface electric field and reduce peak field intensity. These methods are critical in high-voltage devices such as silicon carbide (SiC) and gallium nitride (GaN) power transistors to improve performance and longevity.

Importance of Electric Field Management in Power Devices

Effective electric field management in power devices is crucial to prevent premature breakdown and enhance reliability. Edge termination techniques, such as junction termination extensions (JTE), spread the electric field at device peripheries, reducing peak field intensity. Field plates further optimize this by modulating the surface electric field distribution, improving breakdown voltage and minimizing leakage currents in high-voltage semiconductor components.

Edge Termination: Concept and Types

Edge termination refers to techniques used in power semiconductor devices to manage electric field distribution at the device periphery, preventing premature breakdown. Common types include Junction Termination Extension (JTE), Guard Rings, and Floating Field Rings, each designed to spread the electric field and enhance breakdown voltage. Proper edge termination improves device reliability and performance by minimizing edge-related electric field crowding and surface leakage currents.

Field Plate: Definition and Working Principle

Field plates are semiconductor devices used to improve the electric field distribution at the edges of power devices, preventing premature breakdown and enhancing reliability. They work by extending a conductive plate over the device's edge termination area, modulating the electric field and reducing peak field intensity through capacitive coupling. This technique enhances the voltage handling capability and reduces surface charge accumulation, improving overall device performance.

Comparative Analysis: Edge Termination vs Field Plate

Edge termination techniques primarily focus on controlling electric field distribution at the device periphery to prevent premature breakdown and enhance voltage stability. In contrast, field plates actively modulate gate-to-drain capacitance and improve electric field uniformity by extending the gate electrode, which reduces peak electric fields and improves device reliability. Comparative analysis reveals that field plates offer superior performance in high-voltage applications by minimizing leakage currents and enhancing breakdown voltage, while edge termination provides simpler fabrication and effective field management for lower to moderate voltage devices.

Advantages and Limitations of Edge Termination

Edge termination enhances the voltage blocking capability of power devices by controlling the electric field distribution at the device periphery. Its advantages include simplicity in fabrication and reduced device area compared to field plates, leading to lower manufacturing costs and improved yield. Limitations involve sensitivity to process variations and inadequate field management in high-voltage applications, often requiring complementary techniques for optimal performance.

Benefits and Challenges of Field Plate Implementation

Field plate implementation in power semiconductor devices enhances electric field distribution, reducing surface electric field peaks and improving device reliability under high voltage stress. The benefits include minimized leakage current, higher breakdown voltage, and improved ruggedness, making field plates ideal for high-voltage applications. Challenges involve increased fabrication complexity, potential capacitance increase that may affect switching speed, and the requirement for precise design optimization to balance performance and cost.

Impact on Breakdown Voltage and Device Reliability

Edge termination techniques, such as beveling or junction termination extensions, optimize the electric field distribution at device peripheries, significantly enhancing breakdown voltage by preventing premature edge breakdown. Field plate structures improve device reliability by reducing surface electric fields and minimizing charge trapping effects, which extends lifespan under high voltage stress. Comparing both, edge termination primarily boosts maximum breakdown voltage, while field plates offer superior long-term reliability under repetitive high-voltage operation.

Application Areas for Edge Termination and Field Plate

Edge termination is extensively applied in high-voltage power devices such as insulated-gate bipolar transistors (IGBTs) and power diodes, where controlling electric field distribution at device peripheries is crucial to prevent premature breakdown. Field plates are commonly utilized in advanced semiconductor components like GaN-based high electron mobility transistors (HEMTs) and silicon carbide (SiC) MOSFETs to enhance reliability and performance by reducing electric field crowding and improving breakdown voltage. Your choice between edge termination and field plate techniques depends on the specific device architecture, voltage requirements, and application environment.

Future Trends in Electric Field Optimization Techniques

Future trends in electric field optimization techniques emphasize the integration of advanced edge termination structures with innovative field plate designs to enhance breakdown voltage and reduce leakage currents in power devices. Emerging materials such as high-k dielectrics and the application of novel fabrication methods like atomic layer deposition enable more precise control of electric field distribution at device edges. This synergy between edge termination and field plate technology is driving improvements in efficiency, reliability, and miniaturization of next-generation semiconductor components.

Edge termination vs Field plate Infographic

electrown.com

electrown.com