Piezo injectors offer faster response times and more precise fuel delivery compared to solenoid injectors, resulting in improved engine efficiency and lower emissions. Discover how choosing the right injector can optimize Your vehicle's performance in the rest of this article.

Table of Comparison

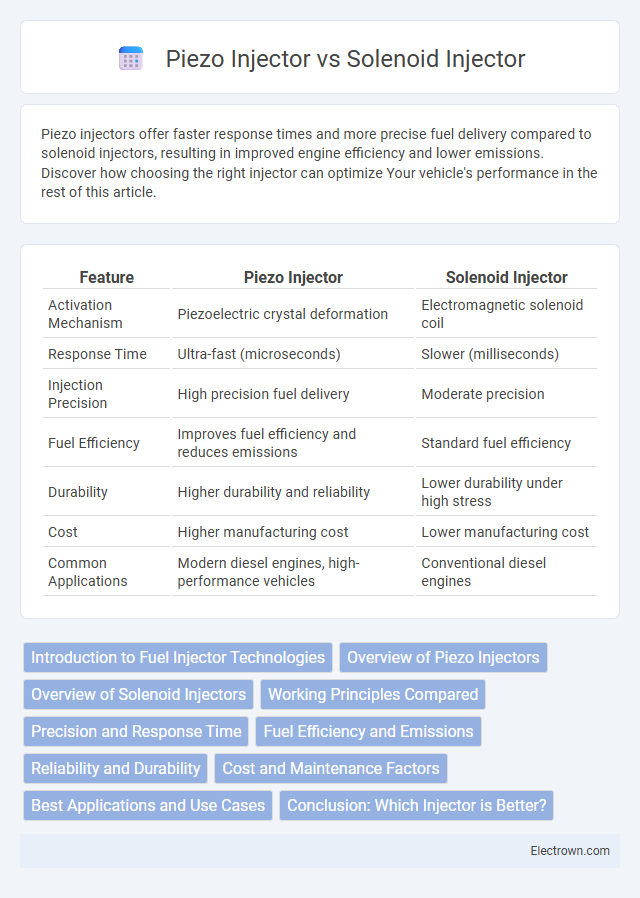

| Feature | Piezo Injector | Solenoid Injector |

|---|---|---|

| Activation Mechanism | Piezoelectric crystal deformation | Electromagnetic solenoid coil |

| Response Time | Ultra-fast (microseconds) | Slower (milliseconds) |

| Injection Precision | High precision fuel delivery | Moderate precision |

| Fuel Efficiency | Improves fuel efficiency and reduces emissions | Standard fuel efficiency |

| Durability | Higher durability and reliability | Lower durability under high stress |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Common Applications | Modern diesel engines, high-performance vehicles | Conventional diesel engines |

Introduction to Fuel Injector Technologies

Piezo injectors utilize piezoelectric crystals to achieve faster and more precise fuel injection timing compared to solenoid injectors, which rely on electromagnetic coils. Your engine's combustion efficiency can improve with piezo technology due to finer control over fuel atomization and injection patterns. Solenoid injectors remain popular for their cost-effectiveness and simpler design but generally offer slower response times and less precise fuel delivery.

Overview of Piezo Injectors

Piezo injectors use piezoelectric crystals to precisely control fuel injection timing and quantity, enabling finer atomization and improved combustion efficiency compared to traditional solenoid injectors. Their rapid response time and multiple injection capabilities enhance engine performance and reduce emissions, making them ideal for modern diesel engines. You benefit from better fuel economy and lower exhaust pollutants when using piezo injectors over solenoid types.

Overview of Solenoid Injectors

Solenoid injectors operate using an electromagnetic coil that controls the needle valve, providing fuel injection through rapid opening and closing actions. This technology is widely employed in diesel engines due to its reliability, lower manufacturing cost, and ease of maintenance compared to piezo injectors. Solenoid injectors generally offer sufficient precision for many fuel injection systems but may lack the ultra-fine control and faster response times enabled by piezoelectric injectors in advanced applications.

Working Principles Compared

Piezo injectors operate using a stack of piezoelectric crystals that expand and contract instantly when voltage is applied, allowing extremely precise control over fuel injection timing and quantity. In contrast, solenoid injectors rely on an electromagnetic coil to move a plunger that opens and closes the injector nozzle, resulting in slightly slower response times and less precise fuel delivery. Understanding your engine's requirements can help determine whether the high-speed accuracy of piezo injectors or the cost-effective reliability of solenoid injectors is more suitable for optimal performance.

Precision and Response Time

Piezo injectors provide superior precision and faster response times compared to solenoid injectors due to their ability to control fuel injection with high-frequency vibrations, enabling multiple injection events per cycle. This precise control enhances combustion efficiency, reduces emissions, and improves engine performance. Your engine benefits from smoother power delivery and better fuel economy when equipped with piezo injector technology.

Fuel Efficiency and Emissions

Piezo injectors deliver more precise fuel atomization and faster response times compared to solenoid injectors, resulting in improved fuel efficiency and reduced fuel consumption. The enhanced control of injection timing and quantity with piezo injectors significantly lowers harmful emissions such as NOx and particulate matter. Studies confirm that engines equipped with piezo injectors achieve better combustion efficiency, contributing to cleaner exhaust profiles and compliance with stringent emission standards.

Reliability and Durability

Piezo injectors offer superior reliability and durability compared to solenoid injectors due to their faster response time and precise fuel control, which reduces wear and tear. Their solid-state design minimizes mechanical friction, enhancing longevity under high-pressure conditions in modern engines. Choosing piezo injectors can extend your engine's performance lifespan while maintaining consistent fuel injection accuracy.

Cost and Maintenance Factors

Piezo injectors typically have a higher upfront cost due to their advanced design and precision components but offer improved fuel efficiency and reduced emissions, which can lower long-term expenses. Solenoid injectors are generally less expensive to purchase and maintain, with simpler mechanics leading to easier servicing and replacement. Your choice between these injectors should consider initial investment against potential savings on fuel and maintenance over time.

Best Applications and Use Cases

Piezo injectors excel in high-performance diesel engines and modern passenger vehicles due to their precise fuel atomization and rapid response times, enhancing fuel efficiency and reducing emissions. Solenoid injectors are best suited for budget-friendly or older engine designs where durability and simplicity are prioritized over ultra-precise fuel delivery. Your choice depends on the specific engine requirements and performance goals, with piezo injectors favored for advanced applications and solenoid injectors for cost-effective solutions.

Conclusion: Which Injector is Better?

Piezo injectors offer precise fuel delivery with faster response times and higher injection pressures, enhancing engine efficiency and lower emissions compared to solenoid injectors. Solenoid injectors remain a cost-effective solution with simpler design and widespread availability, suitable for less demanding applications. Your choice depends on whether priority lies in performance and emissions control (piezo) or budget and simplicity (solenoid).

Piezo injector vs Solenoid injector Infographic

electrown.com

electrown.com