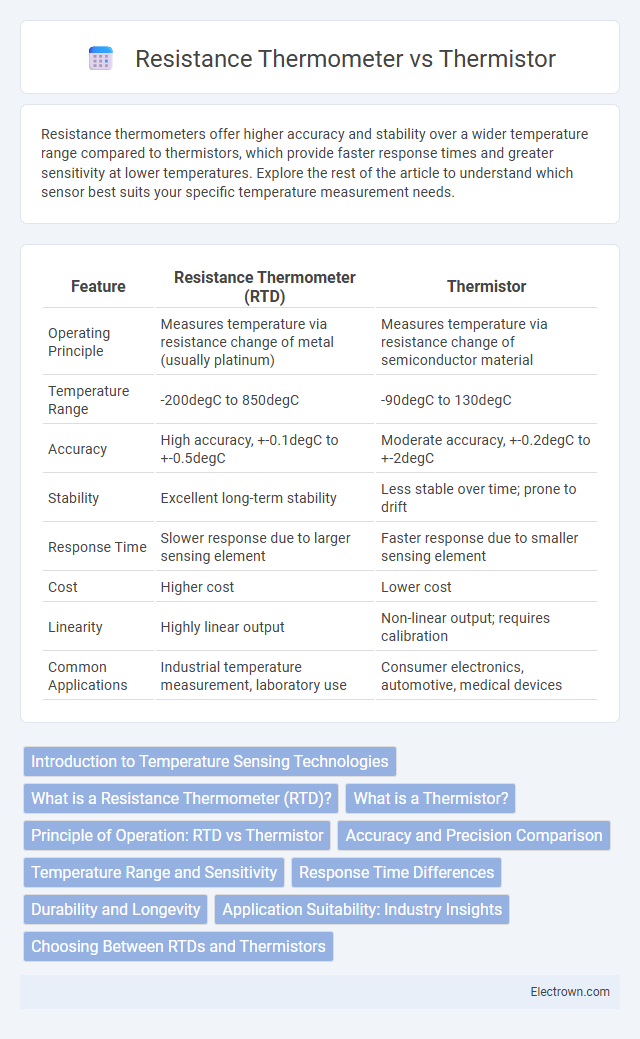

Resistance thermometers offer higher accuracy and stability over a wider temperature range compared to thermistors, which provide faster response times and greater sensitivity at lower temperatures. Explore the rest of the article to understand which sensor best suits your specific temperature measurement needs.

Table of Comparison

| Feature | Resistance Thermometer (RTD) | Thermistor |

|---|---|---|

| Operating Principle | Measures temperature via resistance change of metal (usually platinum) | Measures temperature via resistance change of semiconductor material |

| Temperature Range | -200degC to 850degC | -90degC to 130degC |

| Accuracy | High accuracy, +-0.1degC to +-0.5degC | Moderate accuracy, +-0.2degC to +-2degC |

| Stability | Excellent long-term stability | Less stable over time; prone to drift |

| Response Time | Slower response due to larger sensing element | Faster response due to smaller sensing element |

| Cost | Higher cost | Lower cost |

| Linearity | Highly linear output | Non-linear output; requires calibration |

| Common Applications | Industrial temperature measurement, laboratory use | Consumer electronics, automotive, medical devices |

Introduction to Temperature Sensing Technologies

Resistance thermometers use the predictable change in electrical resistance of metals like platinum to measure temperature with high accuracy over a wide range. Thermistors, composed of semiconductor materials, exhibit a rapid resistance change at specific temperatures, making them ideal for precise, localized sensing in limited temperature ranges. Choosing between these temperature sensing technologies depends on your application's required accuracy, temperature range, and response time.

What is a Resistance Thermometer (RTD)?

A Resistance Thermometer (RTD) is a temperature sensor that measures temperature by correlating the resistance of a metal, typically platinum, to temperature changes. RTDs offer high accuracy, stability, and repeatability, making them ideal for industrial and scientific applications requiring precise temperature measurement. Their resistance increases predictably with temperature, allowing for reliable monitoring across a wide temperature range.

What is a Thermistor?

A thermistor is a highly sensitive temperature sensor made from semiconductor materials that exhibit a significant change in electrical resistance with temperature variations. Unlike resistance thermometers, which use metal elements such as platinum, thermistors provide rapid response times and greater sensitivity within a narrower temperature range, making them ideal for precise temperature measurements in medical devices and HVAC systems. Your choice between a thermistor and resistance thermometer depends on the specific accuracy, temperature range, and response speed required for your application.

Principle of Operation: RTD vs Thermistor

Resistance Thermometers (RTDs) operate on the principle that the electrical resistance of metals increases predictably with temperature, offering high accuracy and stability over a wide range. Thermistors rely on semiconductor materials whose resistance changes exponentially with temperature, providing rapid response but typically with a narrower temperature range. Your choice depends on whether precise, linear resistance changes (RTD) or fast, sensitive detection (thermistor) suits your application.

Accuracy and Precision Comparison

Resistance thermometers (RTDs) offer higher accuracy and precision compared to thermistors, with typical accuracies of +-0.1degC to +-0.5degC, making them ideal for industrial and laboratory applications. Thermistors exhibit greater sensitivity but often show larger variability and non-linear responses, typically accurate within +-0.2degC to +-1.0degC, which limits their precision in high-accuracy measurements. The stable and repeatable resistance-temperature relationship of RTDs ensures consistent precision over wide temperature ranges, while thermistors perform best in narrower temperature intervals with faster response times.

Temperature Range and Sensitivity

Resistance thermometers typically operate effectively over a wide temperature range from -200degC to 850degC, making them suitable for extreme industrial applications. Thermistors, while limited to a narrower range of approximately -50degC to 150degC, offer significantly higher sensitivity and faster response times within this span. The high sensitivity of thermistors enhances precision in detecting small temperature changes, whereas resistance thermometers provide stable and accurate measurements across broader environmental conditions.

Response Time Differences

Resistance thermometers typically exhibit slower response times due to their larger sensing elements and metal wire construction, which require more time to reach thermal equilibrium. Thermistors, made from semiconductor materials with smaller mass, respond rapidly to temperature changes, often within milliseconds to seconds. This faster response time makes thermistors ideal for applications requiring quick and precise temperature monitoring.

Durability and Longevity

Resistance Thermometers (RTDs) typically offer superior durability and longevity compared to thermistors due to their robust construction using pure metal elements like platinum. RTDs maintain accuracy over a wider temperature range and can withstand harsh industrial environments without significant drift or degradation. Thermistors, made from ceramic or polymer materials, generally exhibit faster response times but are more susceptible to aging and environmental damage, resulting in shorter operational lifespans.

Application Suitability: Industry Insights

Resistance thermometers, such as RTDs, excel in high-precision industrial applications requiring stable and repeatable temperature measurements over a wide range, including chemical processing and aerospace industries. Thermistors offer faster response times and higher sensitivity at lower temperatures, making them ideal for HVAC systems, medical devices, and consumer electronics. Industry insights highlight that RTDs are preferred for their accuracy and durability in harsh environments, while thermistors dominate cost-sensitive and compact applications.

Choosing Between RTDs and Thermistors

Choosing between Resistance Temperature Detectors (RTDs) and thermistors depends on application accuracy, temperature range, and response time requirements. RTDs offer high accuracy and stability over a wide temperature range (-200degC to 850degC), making them ideal for industrial processes, while thermistors provide faster response times and greater sensitivity within a narrower temperature range (-50degC to 150degC), suitable for consumer devices. Cost considerations also play a role; thermistors are generally less expensive and simpler to use, whereas RTDs demand more complex circuitry and calibration but deliver superior precision.

Resistance Thermometer vs Thermistor Infographic

electrown.com

electrown.com