Discrete input signals represent binary states, such as ON/OFF or TRUE/FALSE, commonly used in digital controllers for clear-cut conditions, whereas analog input signals measure continuous variations, like temperature or pressure, providing detailed data for precise control. Understanding the difference between discrete and analog inputs will help you optimize your system's performance; continue reading to explore their applications and advantages.

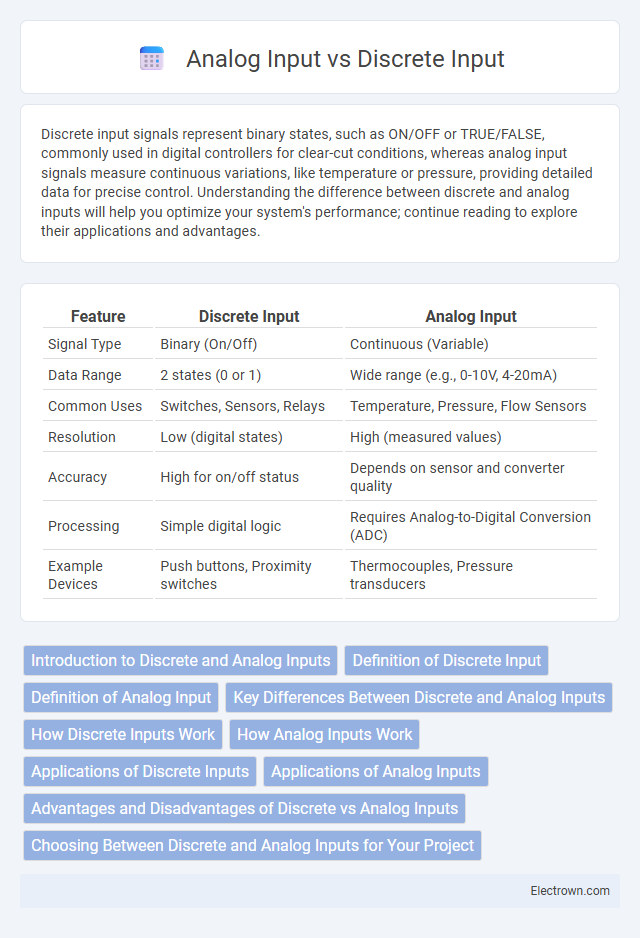

Table of Comparison

| Feature | Discrete Input | Analog Input |

|---|---|---|

| Signal Type | Binary (On/Off) | Continuous (Variable) |

| Data Range | 2 states (0 or 1) | Wide range (e.g., 0-10V, 4-20mA) |

| Common Uses | Switches, Sensors, Relays | Temperature, Pressure, Flow Sensors |

| Resolution | Low (digital states) | High (measured values) |

| Accuracy | High for on/off status | Depends on sensor and converter quality |

| Processing | Simple digital logic | Requires Analog-to-Digital Conversion (ADC) |

| Example Devices | Push buttons, Proximity switches | Thermocouples, Pressure transducers |

Introduction to Discrete and Analog Inputs

Discrete inputs represent binary signals, typically indicating on/off or true/false states, commonly used in digital control systems and industrial automation for monitoring switches, sensors, and relays. Analog inputs capture continuous signals varying over a range, such as voltage or current levels, essential for measuring temperature, pressure, or flow in process control applications. Understanding the fundamental differences between discrete and analog inputs enables precise data acquisition and system responsiveness in various engineering and automation contexts.

Definition of Discrete Input

Discrete input refers to a type of digital signal used in control systems and automation, representing binary states such as ON/OFF or TRUE/FALSE. These inputs detect simple, distinct conditions like switch positions, sensor statuses, or push-button activations without intermediate values. Unlike analog inputs that measure continuous variables, discrete inputs provide precise, two-state data essential for logic operations and control decisions.

Definition of Analog Input

Analog input refers to a continuous signal that represents varying physical quantities such as temperature, pressure, or voltage, providing real-time data to control systems. Unlike discrete input, which recognizes only binary states (on/off), analog input captures a range of values within a specific scale, allowing for precise monitoring and control. This type of input is essential in processes requiring fine adjustment and detailed measurement to optimize system performance.

Key Differences Between Discrete and Analog Inputs

Discrete inputs register binary signals representing ON/OFF or TRUE/FALSE states, typically used for digital devices such as switches and sensors. Analog inputs capture continuous signals varying in voltage or current, enabling precise measurement of variables like temperature, pressure, and flow. The key difference lies in data type: discrete inputs process digital signals with two distinct values, whereas analog inputs handle a range of values, requiring analog-to-digital conversion for analysis.

How Discrete Inputs Work

Discrete inputs function by detecting binary states, typically represented as ON or OFF signals, to monitor the status of devices such as switches or sensors. These inputs send a simple high or low voltage signal to a control system, allowing you to track the presence or absence of an event with clear, unambiguous data. Their design ensures rapid response times and reliable operation in automation and control processes.

How Analog Inputs Work

Analog inputs convert continuous physical signals such as temperature, pressure, or voltage into corresponding electrical signals that a control system can process. These inputs utilize sensors like thermocouples or potentiometers to generate variable voltage or current levels representing real-world measurements. Your system then interprets these analog signals to monitor and regulate processes with precise and real-time data.

Applications of Discrete Inputs

Discrete inputs are commonly used in industrial automation for monitoring the status of devices such as switches, push buttons, and emergency stop circuits, providing binary on/off signals for precise control. They enable your control systems to detect simple events, such as the presence or absence of objects on conveyor belts or the open/closed state of safety guards. These inputs are essential for applications requiring quick, reliable digital data to trigger specific machine actions or safety protocols.

Applications of Analog Inputs

Analog inputs are essential for applications requiring continuous signal monitoring, such as temperature control in HVAC systems, pressure measurement in industrial processes, and speed detection in motor controls. These inputs accurately capture varying voltage or current levels, enabling precise adjustments and real-time data analysis. Your automation system benefits from analog inputs by enhancing process control accuracy and ensuring smooth operation in dynamic environments.

Advantages and Disadvantages of Discrete vs Analog Inputs

Discrete inputs offer advantages such as simple on/off status detection and easy integration with digital systems, making them ideal for binary signals like switches and sensors. However, their limitations include inability to provide variable measurements and lack of precision compared to analog inputs, which excel in representing continuous signals such as temperature, pressure, or voltage with high accuracy. Analog inputs require more complex processing and are susceptible to noise interference, but their ability to capture detailed variations makes them essential for precise control and monitoring applications.

Choosing Between Discrete and Analog Inputs for Your Project

Choosing between discrete and analog inputs depends on the type of data your project requires. Discrete inputs handle simple, binary signals like on/off or open/closed states, ideal for detecting switches or sensors with two states. Analog inputs process variable signals, such as temperature or pressure, providing a continuous range of values essential for precise monitoring and control in automation systems.

Discrete Input vs Analog Input Infographic

electrown.com

electrown.com