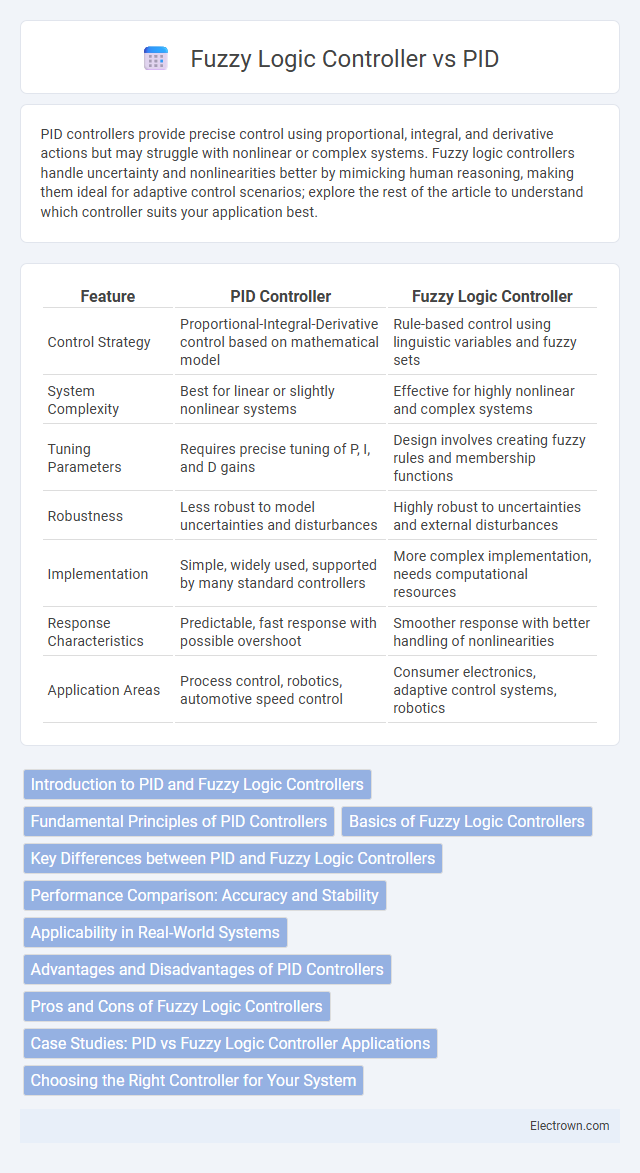

PID controllers provide precise control using proportional, integral, and derivative actions but may struggle with nonlinear or complex systems. Fuzzy logic controllers handle uncertainty and nonlinearities better by mimicking human reasoning, making them ideal for adaptive control scenarios; explore the rest of the article to understand which controller suits your application best.

Table of Comparison

| Feature | PID Controller | Fuzzy Logic Controller |

|---|---|---|

| Control Strategy | Proportional-Integral-Derivative control based on mathematical model | Rule-based control using linguistic variables and fuzzy sets |

| System Complexity | Best for linear or slightly nonlinear systems | Effective for highly nonlinear and complex systems |

| Tuning Parameters | Requires precise tuning of P, I, and D gains | Design involves creating fuzzy rules and membership functions |

| Robustness | Less robust to model uncertainties and disturbances | Highly robust to uncertainties and external disturbances |

| Implementation | Simple, widely used, supported by many standard controllers | More complex implementation, needs computational resources |

| Response Characteristics | Predictable, fast response with possible overshoot | Smoother response with better handling of nonlinearities |

| Application Areas | Process control, robotics, automotive speed control | Consumer electronics, adaptive control systems, robotics |

Introduction to PID and Fuzzy Logic Controllers

PID controllers use proportional, integral, and derivative terms to regulate system output by minimizing error and ensuring stability in linear control applications. Fuzzy Logic Controllers apply rule-based reasoning with linguistic variables to handle uncertainty and nonlinear systems, mimicking human decision-making. Your choice depends on the system's complexity, with PID suited for precise, well-defined processes and fuzzy logic excelling in ambiguous or complex environments.

Fundamental Principles of PID Controllers

PID controllers operate based on three fundamental principles: proportional, integral, and derivative control. The proportional component reduces the error by applying a correction proportional to the current error value. The integral adjusts for accumulated past errors, while the derivative predicts future error trends, resulting in precise and stable system performance.

Basics of Fuzzy Logic Controllers

Fuzzy Logic Controllers (FLC) rely on linguistic variables and fuzzy sets rather than precise numerical inputs, offering a flexible and approximate reasoning approach ideal for complex or nonlinear systems. Unlike traditional PID controllers that use fixed mathematical models, FLC mimics human decision-making by applying fuzzy rules and membership functions to handle uncertainty and imprecision. Your system benefits from enhanced adaptability and robustness when fuzzy logic effectively manages ambiguous data where conventional PID controllers may struggle.

Key Differences between PID and Fuzzy Logic Controllers

PID controllers rely on precise mathematical models and fixed control rules based on proportional, integral, and derivative terms, whereas Fuzzy Logic Controllers use linguistic variables and approximate reasoning to handle uncertainties and nonlinearities. PID control excels in linear systems with predictable behavior, while fuzzy logic controllers adapt better to complex, nonlinear processes without requiring an exact model. The tuning process for PID involves adjusting gain parameters for stability, whereas fuzzy controllers optimize membership functions and rule sets to emulate human decision-making.

Performance Comparison: Accuracy and Stability

PID controllers offer precise control with straightforward tuning, delivering consistent accuracy in linear systems but can struggle with nonlinearity and disturbances, affecting stability. Fuzzy Logic Controllers excel in handling system uncertainties and nonlinearities, maintaining robust stability and adaptive accuracy without requiring an explicit mathematical model. Comparative studies show Fuzzy Logic Controllers outperform PID in complex, dynamic environments by providing smoother responses and greater resilience to parameter variations.

Applicability in Real-World Systems

PID controllers excel in industrial systems requiring precise, linear control like temperature regulation and motor speed, where system dynamics are well-understood and stable. Fuzzy Logic Controllers thrive in complex, nonlinear environments such as robotics and automotive systems by mimicking human reasoning to handle uncertainty and adapt to changing conditions. Your choice depends on whether your application demands straightforward control with predictable responses or flexible handling of ambiguous, dynamic inputs.

Advantages and Disadvantages of PID Controllers

PID controllers excel in simplicity and ease of implementation, offering reliable performance for a wide range of linear control systems with well-defined parameters. Their primary advantage lies in precise control through proportional, integral, and derivative actions, which help minimize steady-state error and improve transient response. However, PID controllers struggle with nonlinearities and parameter variations, often requiring manual tuning and sometimes failing to adapt effectively to complex or rapidly changing environments, where fuzzy logic controllers may perform better.

Pros and Cons of Fuzzy Logic Controllers

Fuzzy Logic Controllers (FLCs) offer advantages such as handling nonlinear systems effectively and tolerating uncertainties without requiring precise mathematical models, making them suitable for complex or ill-defined processes. However, their design relies heavily on expert knowledge for rule formulation, which can be time-consuming and subjective, and performance may degrade if rules are not properly tuned. Compared to PID controllers, FLCs can provide smoother control in dynamic environments but often demand higher computational resources and lack standardized design methods.

Case Studies: PID vs Fuzzy Logic Controller Applications

Case studies reveal PID controllers excel in linear, well-modeled systems like temperature regulation in industrial furnaces, offering simplicity and reliability. Fuzzy Logic Controllers outperform in complex, nonlinear environments such as autonomous vehicle navigation, where handling uncertainty and imprecise inputs is crucial. Comparative analyses in robotics demonstrate Fuzzy Logic's adaptability, while PID remains favored for precise, stable control in process industries.

Choosing the Right Controller for Your System

Choosing the right controller for your system depends on the complexity and nature of the process being controlled. PID controllers excel in systems with linear dynamics and well-defined parameters, offering straightforward tuning and reliable performance. Fuzzy Logic Controllers provide advantages in handling nonlinearities and uncertainties by mimicking human reasoning, making them suitable for complex, ambiguous environments where precise mathematical models are unavailable.

PID vs Fuzzy Logic Controller Infographic

electrown.com

electrown.com